Correction method and correction system of photosensitive circuit board

A technology of calibration system and calibration method, which is applied in the field of calibration methods and calibration systems of photosensitive circuit boards, to achieve the effects of good factory performance consistency, cost saving, and circuit board structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

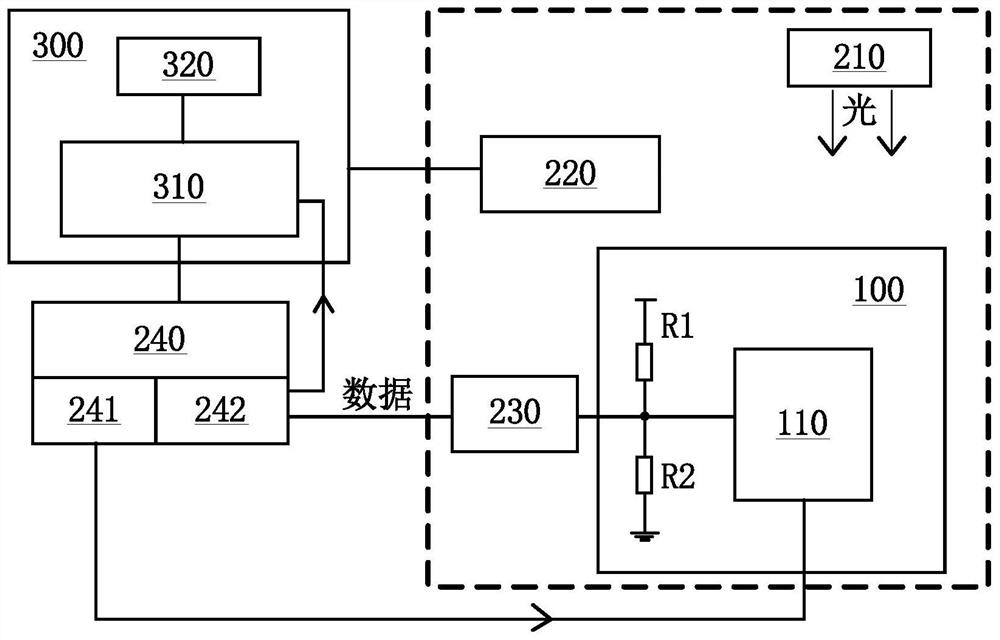

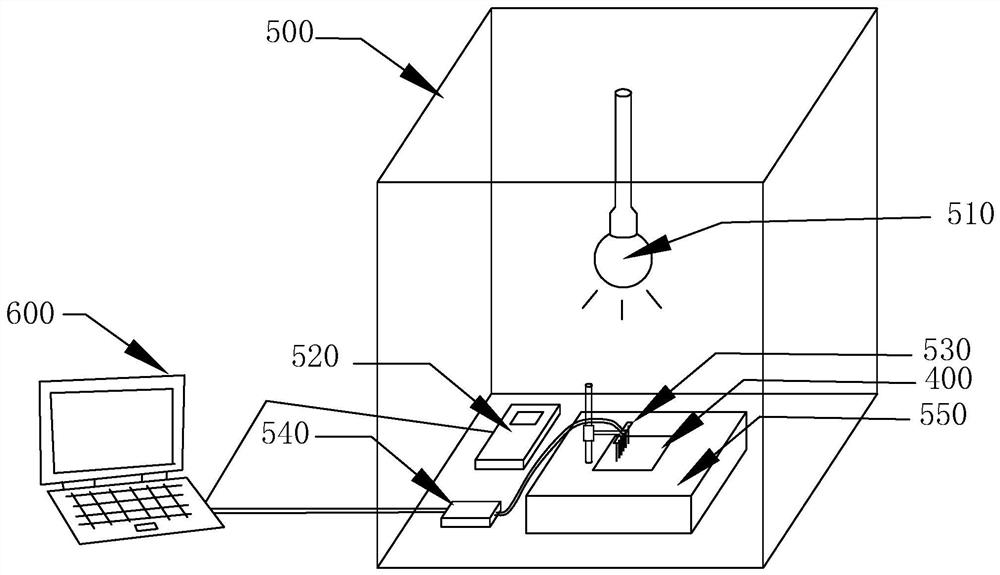

[0025] The invention provides a new correction method for a photosensitive circuit board and a correction system for a photosensitive circuit board. For a clearer representation, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] An embodiment of the present invention provides a method for calibrating a photosensitive circuit board, including:

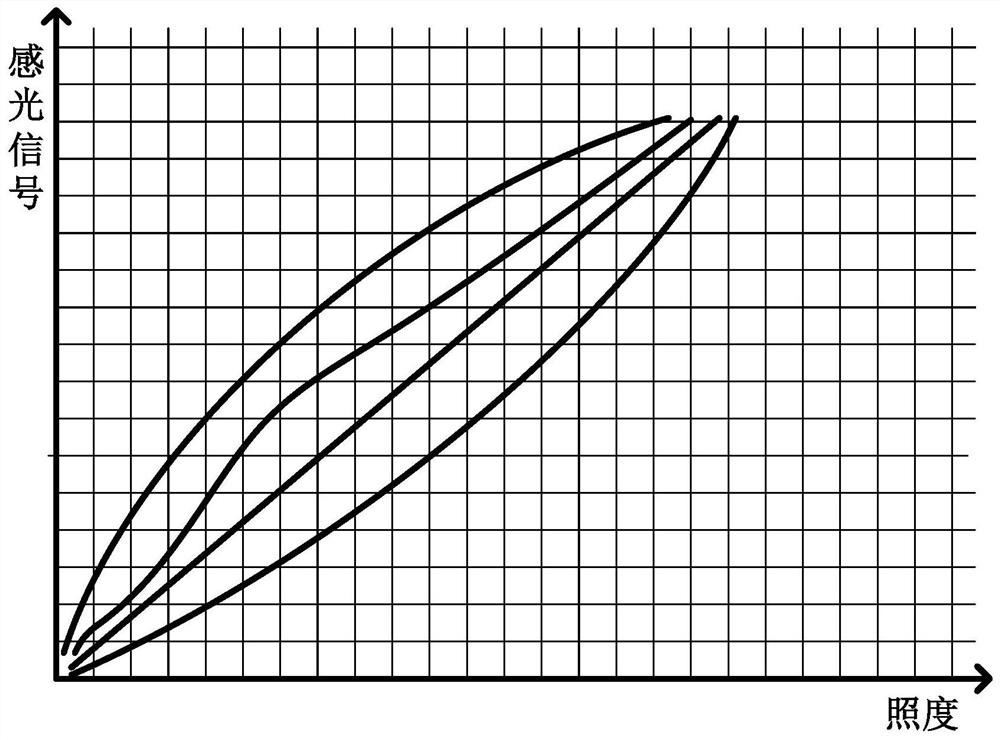

[0027] Use the photosensitive element to collect the combination of illuminance and photosensitive signal data on the unprogrammed photosensitive circuit board;

[0028] In the process of burning the photosensitive circuit board, the illuminance-photosensitive signal data combination collected by the photosensitive element and the source program are recompiled and then burned into the photosensitive circuit board.

[0029] Wherein, performing the collection of the illuminance-photosensitive signal data combination may further include:

[0030] To detect the real-time and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com