Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, vehicle components, etc., and can solve the problem of difficulty in balancing driving stability and snow performance, reduced driving stability on dry roads, and rigidity of the surrounding bank Reduce the problems such as improving moisture resistance and snow performance, maintaining driving stability, and increasing edge components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

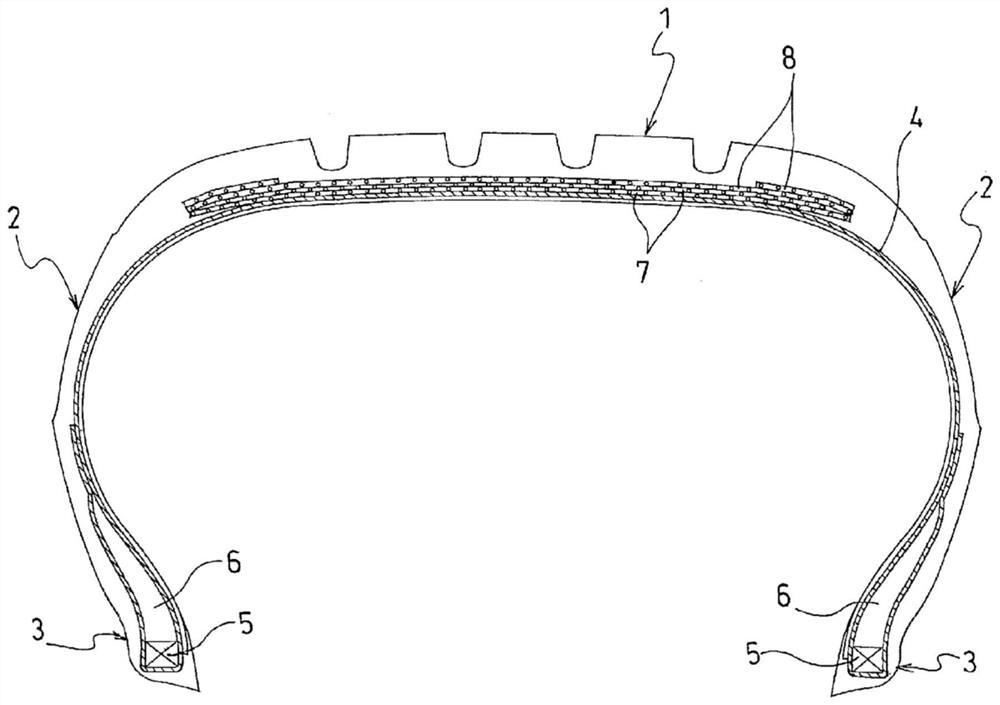

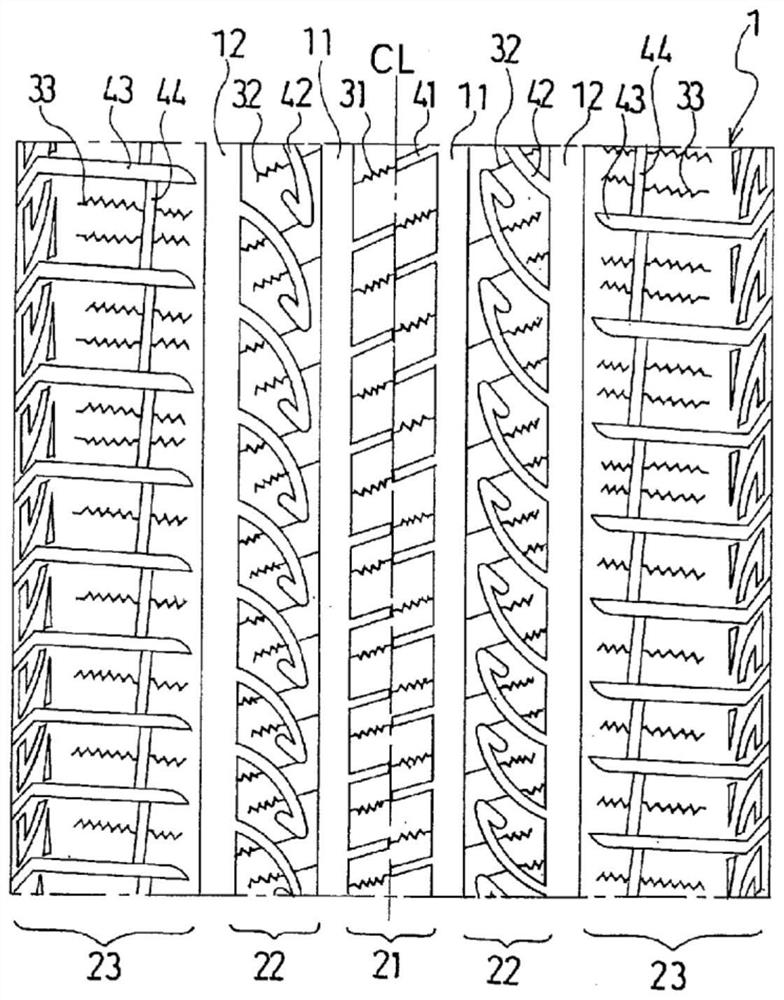

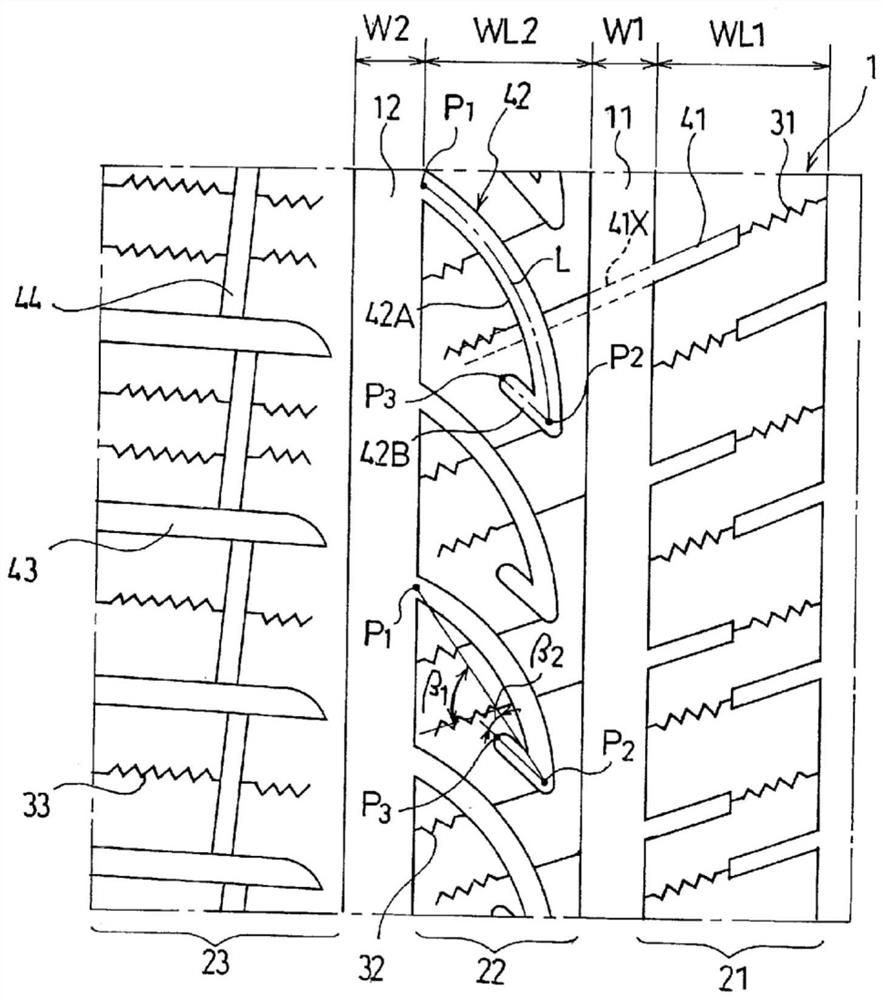

[0047]The tires of Conventional Example, Comparative Examples 1 to 3, and Examples 1 to 5 were manufactured in the following manner, the tire size was 235 / 55R19, the In a pneumatic tire with a pair of sidewall portions on both sides and a pair of bead portions provided on the inner side in the tire radial direction of such sidewall portions, in the tread portion is formed a tire extending in the tire circumferential direction on both sides of the tire equator line. A pair of inner main grooves and a pair of outer main grooves extending in the tire circumferential direction outside the inner main grooves, the central land portion is divided between the pair of inner main grooves, and the middle land portion is divided between the inner main grooves and the inner main grooves. Between the outer main grooves, the shoulder land is divided on the outer side of the outer main groove, and a plurality of sipes are formed in the central land, and a plurality of sipes and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com