Automatic precise tea leaf picking robot

A robotic and precise technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of large picking losses, falling of picked objects, and inability to pick tea leaves, so as to improve the effect of picking and harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

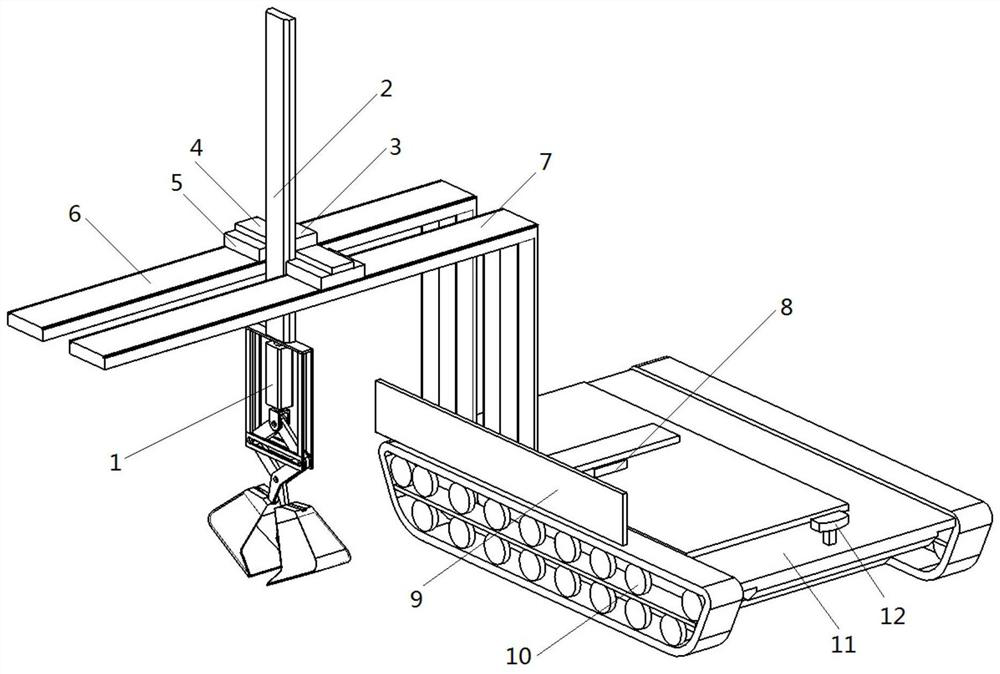

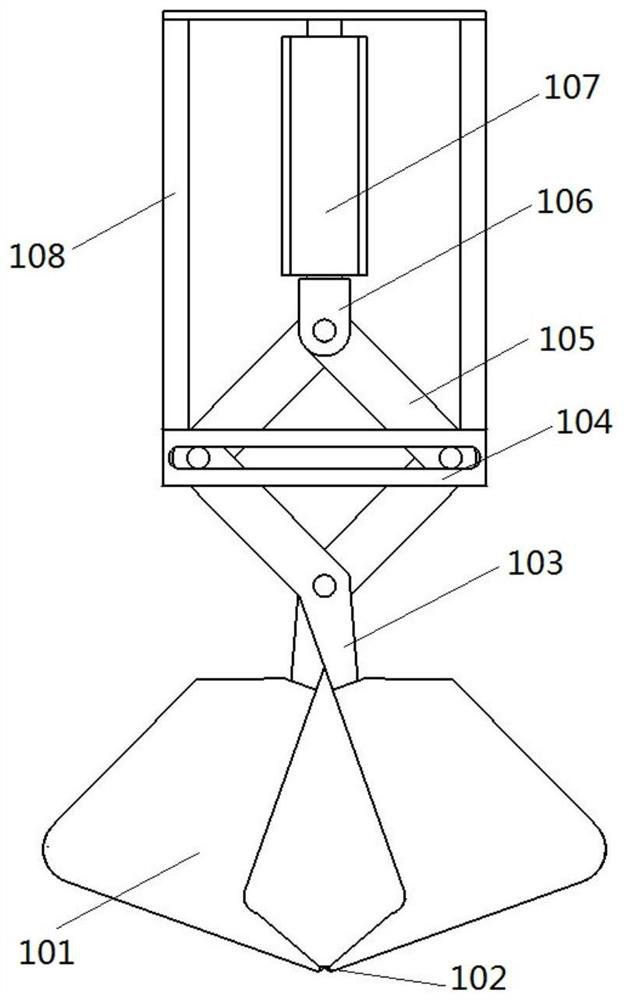

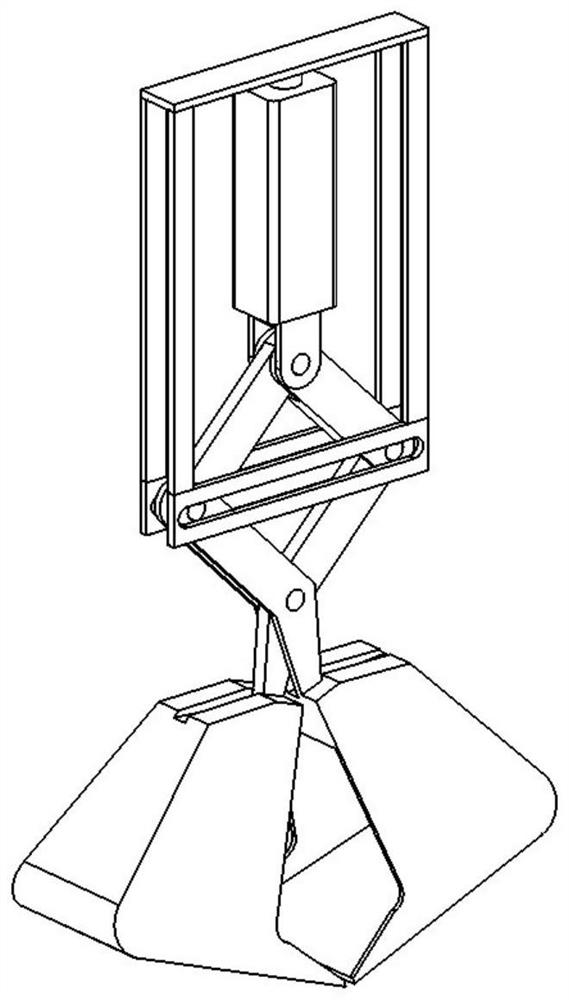

[0030] Such as figure 1 As shown, an automatic and precise tea-picking robot includes a car body 11 that can walk and move in the tea garden. The bottom of the car body 11 is provided with a crawler mechanism 10. A camera 12 and a fixed bracket 8 are installed on the car body 11. The car body 11 A box body with an opening at the top is also provided on the top, and the box body is used to collect tea leaves. In this embodiment, the crawler mechanism 10 is arranged on both sides of the car body 11, and the camera 12 is located directly in front of the car body 11. The box body for collecting tea leaves (i.e. collector) is positioned at the rear side of car body 11, and fixed support 8 is positioned at the top of car body 11 one side;

[0031] The fixed bracket 8 is equipped with a translational drive mechanism and a push plate correction mechanism 9 that can be pushed out and retracted. The push plate correction mechanism 9 is arranged at a position facing the root of the tea t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com