A kind of glass welding method of sintered samarium cobalt permanent magnet

A glass welding and permanent magnet technology, applied in the field of rare earth permanent magnet welding, can solve the problems of magnet rupture and high risk, and achieve the effects of short welding time, low welding temperature and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

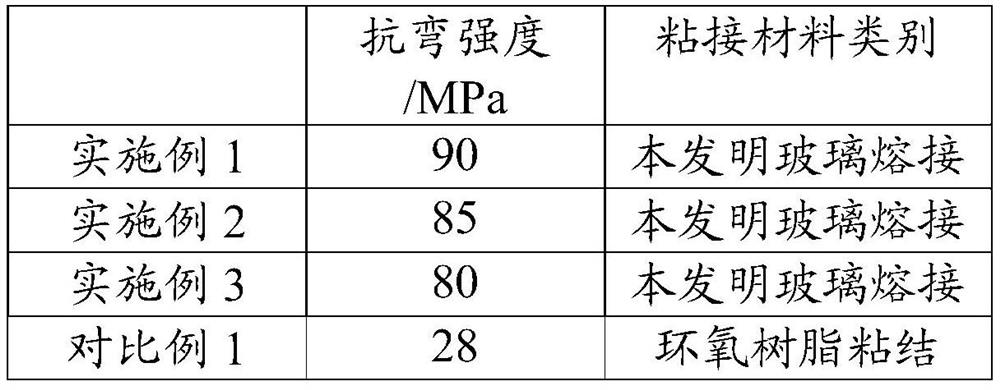

Examples

Embodiment 1

[0030] (1) Select two sintered samarium cobalt permanent magnets that have not been surface plating treatment, process them into 10×10×5mm blocks with wire cutting, sandblasting treatment on the welding surface, the compressed air pressure is 0.5MPa, the sand particles used are 1mm quartz sand, the surface distance between the nozzle and the samarium cobalt is 80mm, the spray angle is 30 °, and it is cleaned and dried with distilled water and acetone, respectively;

[0031] (2) The percentage of glass powder composition by weight is: PbO is 75%, B 2 O 3 10%, Bi 2 O 3 5%, ZnO 9%, SiO 2 0.5%, Al 2 O 3 0.5%. After weighing and mixing various raw materials according to the above ratios, they are placed in a V-type mixer and mixed evenly. The mixed raw materials are placed in the corundum crucible, heated to 800 ° C in the air atmosphere of the silicon carbon rod electric furnace, kept warm for 2 hours, poured into deionized water and quenched, dried, and crushed to below 300 mesh with...

Embodiment 2

[0035](1) Select two sintered samarium cobalt permanent magnets without surface plating treatment, process them into 10×10×5mm blocks with wire cutting, sandblast treatment on the welding surface, the compressed air pressure is 0.6MPa, the sand particles used are 1mm emery, the surface distance between the nozzle and samarium cobalt is 100mm, the spray angle is 40 °, and it is cleaned and dried with distilled water and acetone, respectively;

[0036] (2) The percentage of glass powder composition by weight is: PbO is 70%, B 2 O 3 8%, Bi 2 O 3 10%, ZnO 11.5%, SiO 2 0.3%, Al 2 O 3 0.2%. After weighing and mixing various raw materials according to the above ratios, they are placed in a V-type mixer and mixed evenly. The mixed raw materials are placed in the corundum crucible, heated to 850 ° C in the air atmosphere of the silicon carbon rod electric furnace, kept warm for 2.5 hours, poured into deionized water and quenched, dried, and ground with a ball mill to below 300 mesh. The gl...

Embodiment 3

[0040] (1) Select two sintered samarium cobalt permanent magnets that have not been surface electroplated, processed into 10×10×5mm blocks by wire cutting, sandblasting treatment on the welding surface, compressed air pressure of 0.8MPa, sand particles used for 0.5mm glass beads, nozzle and samarium cobalt surface distance of 110mm, spray angle of 50 °, respectively, with distilled water, acetone cleaning, drying;

[0041] (2) The percentage of glass powder composition by weight is: PbO is 65%, B 2 O 3 7%, Bi 2 O 3 15%, ZnO 12.5%, SiO 2 0.3%, Al 2 O 30.2%. After weighing and mixing various raw materials according to the above ratios, they are placed in a V-type mixer and mixed evenly. The homogeneous raw materials are placed in the corundum crucible, heated to 780 ° C in the air atmosphere of the silicon carbon rod electric furnace, kept warm, after 2.5 hours, poured into deionized water quenching, dried, and ball milled to below 300 mesh with a ball mill. The glass powder prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com