Model test system for measuring characteristics of slurry in shield tunneling machine and control method thereof

A model test and shield machine technology, applied in flow characteristics, teaching models, soil material testing, etc., can solve problems such as difficulty in directly measuring mud data, poor measurement accuracy, etc., and achieve the effect of solving mud data difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

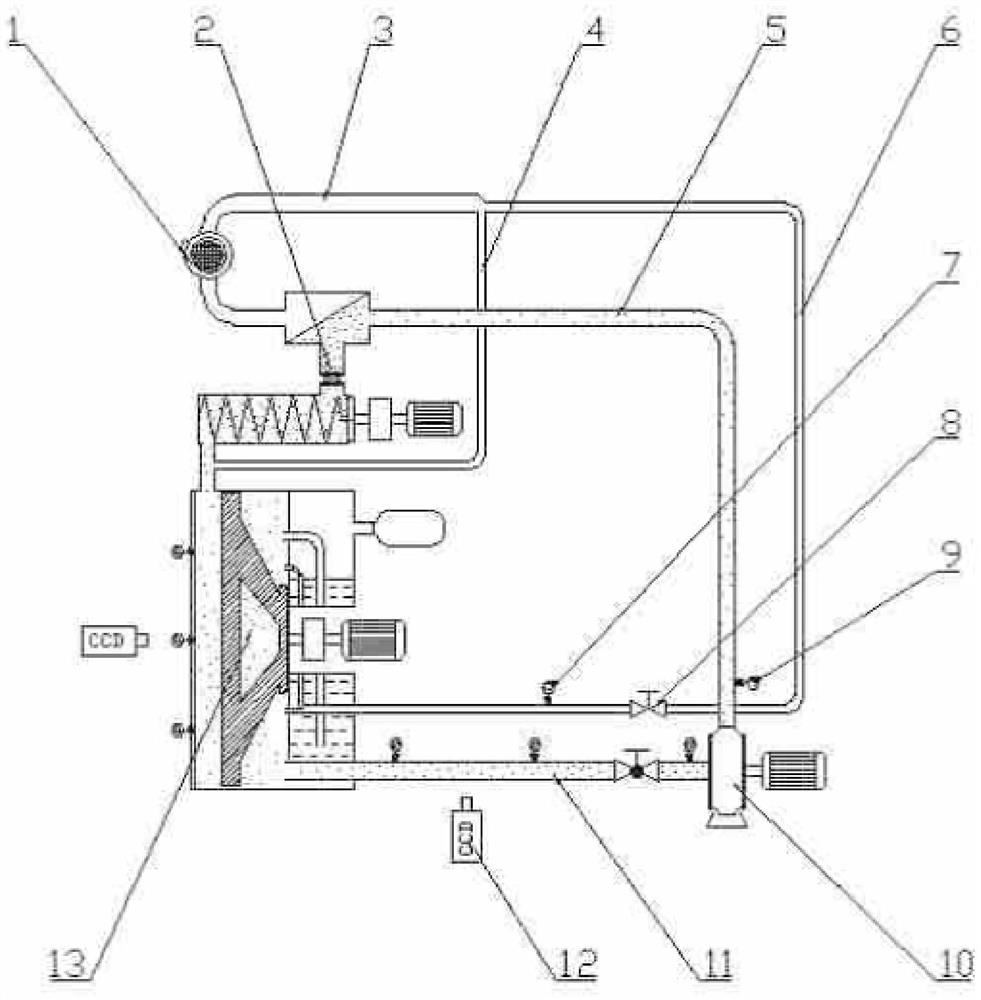

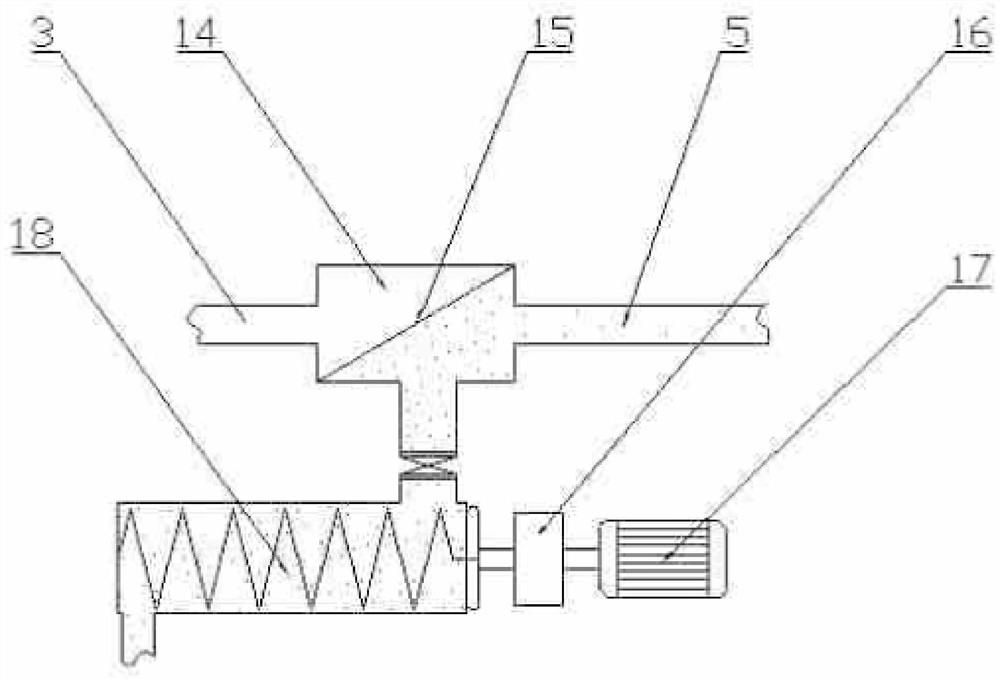

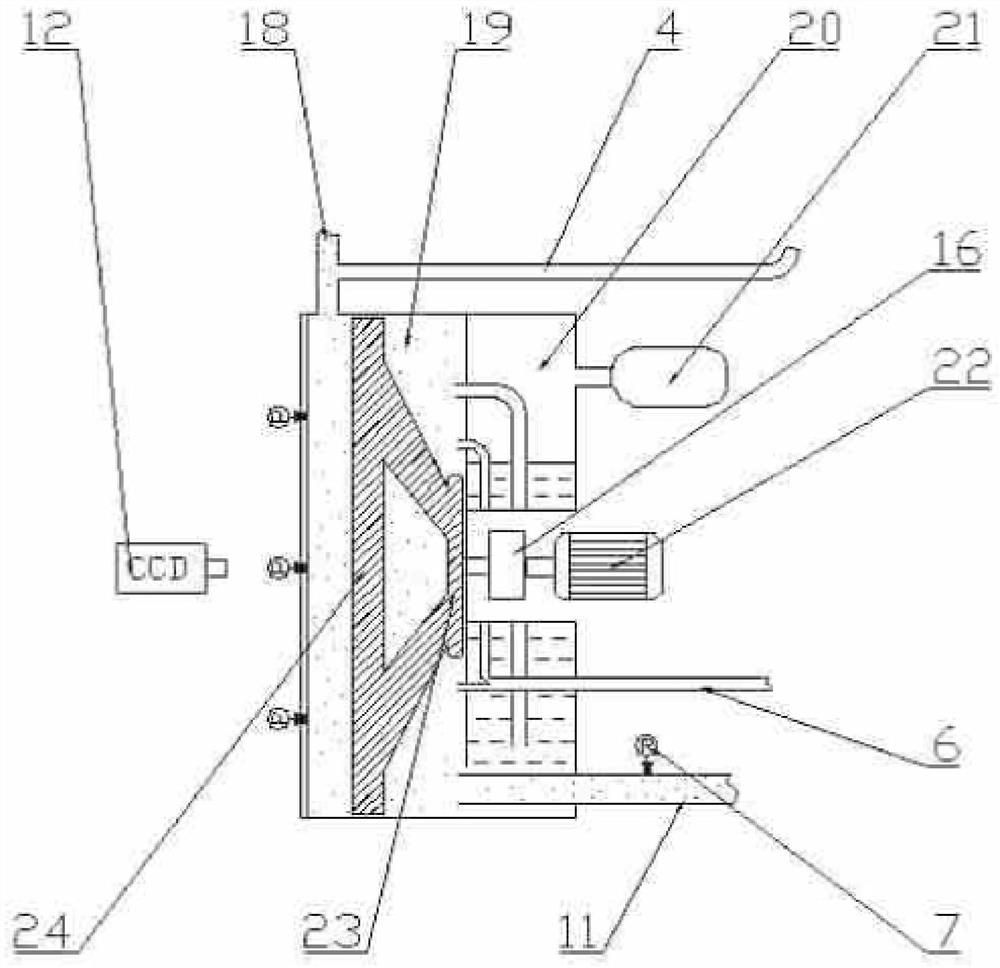

[0039]Embodiment: As shown in the figure, a model test system for measuring the mud characteristics in the shield machine includes a test model assembly 13, the upper end of the test model assembly 13 is provided with a suction pipe 3, and a pipeline is arranged on the suction pipe 3 The pump 1, the pumping pipe 3 and the upper part of the test model assembly 13 are provided with a feeding assembly 2, and the feeding assembly 2 includes a screw feeder 18. The tube 5 is connected to the solid-liquid material cylinder 14. The solid-liquid material cylinder 14 is provided with a filter screen 15 arranged in an oblique direction. The frequency conversion motor 17. Reducer 16 is all provided between frequency conversion motor 17 and screw feeder 18, between low speed motor 22 and runner 23. Between the feeding assembly 2 and the upper part of the test model assembly 13, a primary slurry return pipe 4 connected with the liquid suction pipe 3 is provided, and a displacement pump 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com