Device capable of generating three-dimensional plasma photonic crystals and provided with three discharge air gaps

A plasmonic, photonic crystal technology for plasma applications and optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

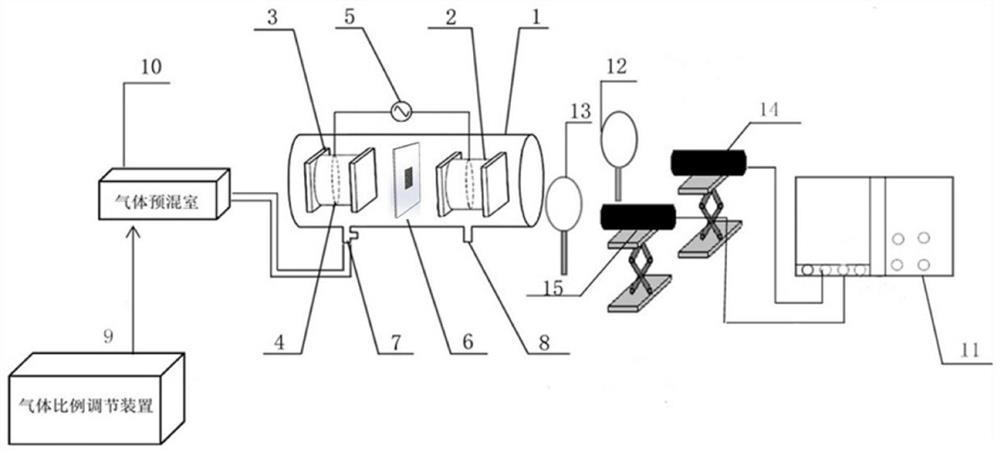

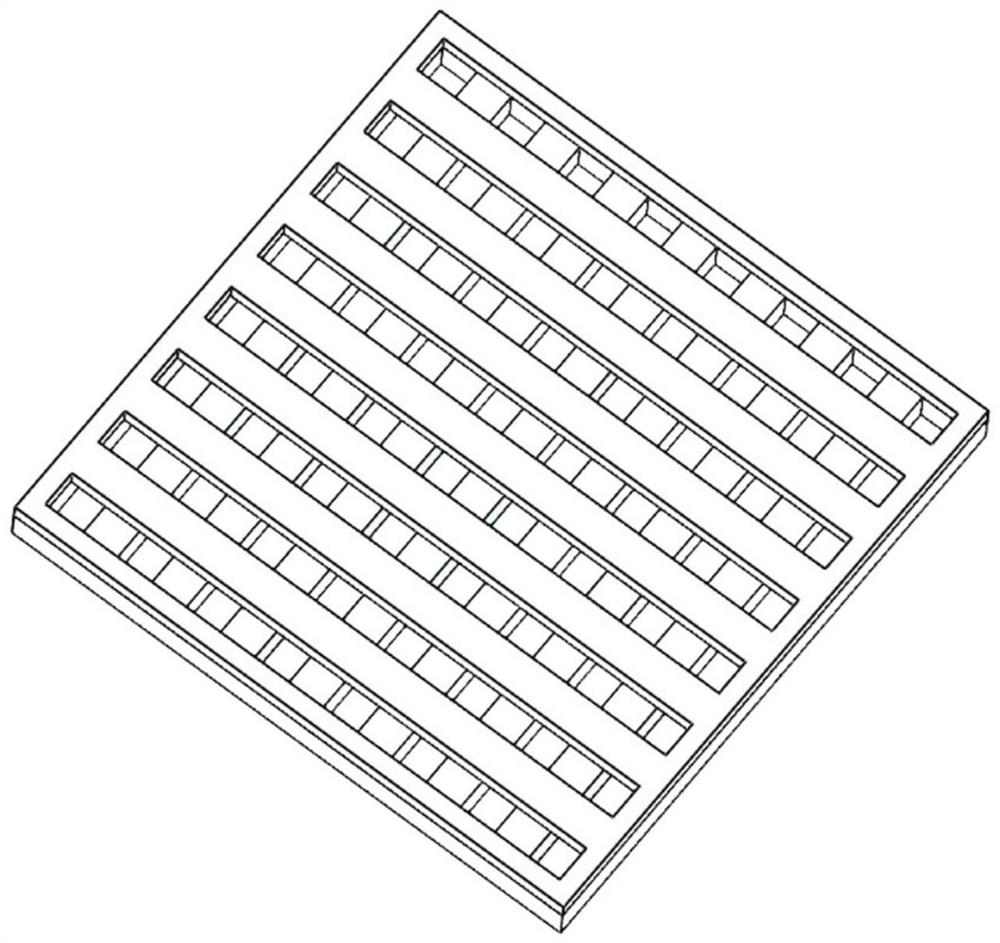

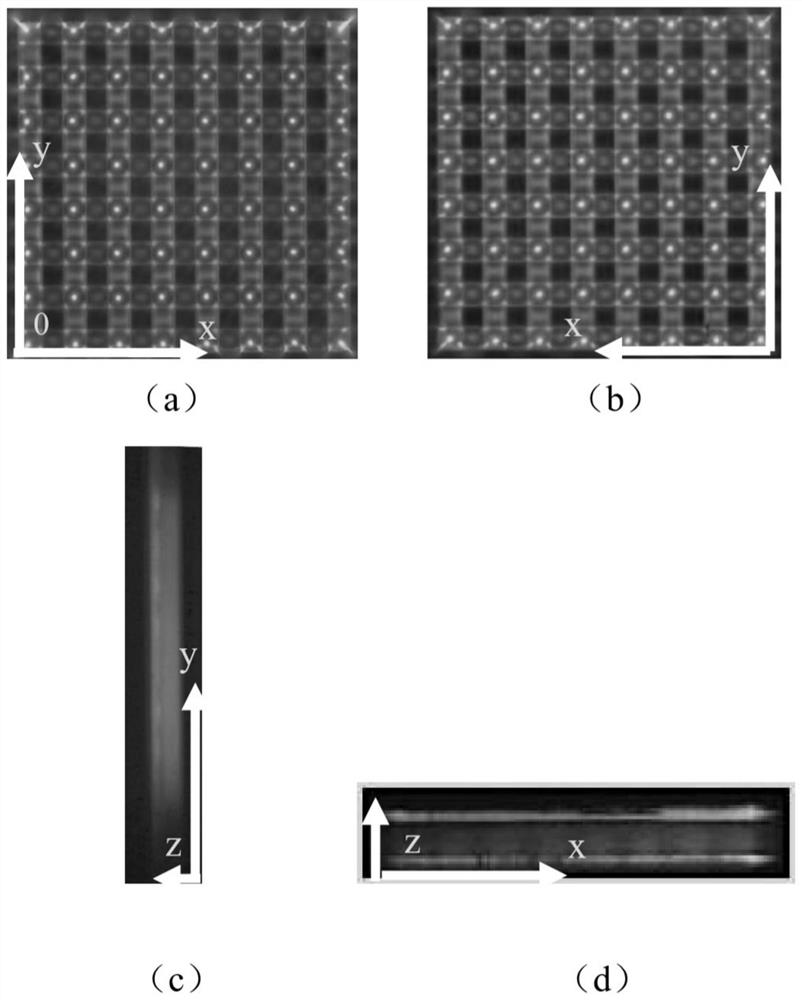

[0026] Such as figure 1 As shown, the device among the present invention comprises a vacuum reaction chamber 1, a plasma generation power supply 5 is arranged outside the vacuum reaction chamber 1, and two water electrodes 2 connected with the plasma generation power supply 5 are provided in the vacuum reaction chamber 1 , between the two water electrodes 2 there are two solid frames 6 that are pasted together. Outside the vacuum reaction chamber 1, a gas ratio adjusting device 9, a gas premixing chamber 10 and a signal collector are also arranged. The signal collector comprises a first optical filter 12, a second optical filter 13, a first photomultiplier tube 14 and a second photomultiplier tube 15, and the first photomultiplier tube 14 and the second photomultiplier tube 15 are all in phase with the oscilloscope 11. connect.

[0027] The vacuum reaction chamber 1 is used to generate plasma photonic crystals therein. The vacuum reaction chamber 1 has a horizontal cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com