A powder output device for laser additive equipment

A laser additive and equipment technology, applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of destroying the uniformity of the tiled powder layer, sticking, and low metal powder reserves, and achieves a reduction in the number of metal powders. Probability of small card death, quantitative and smooth powder output, and the effect of large powder storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

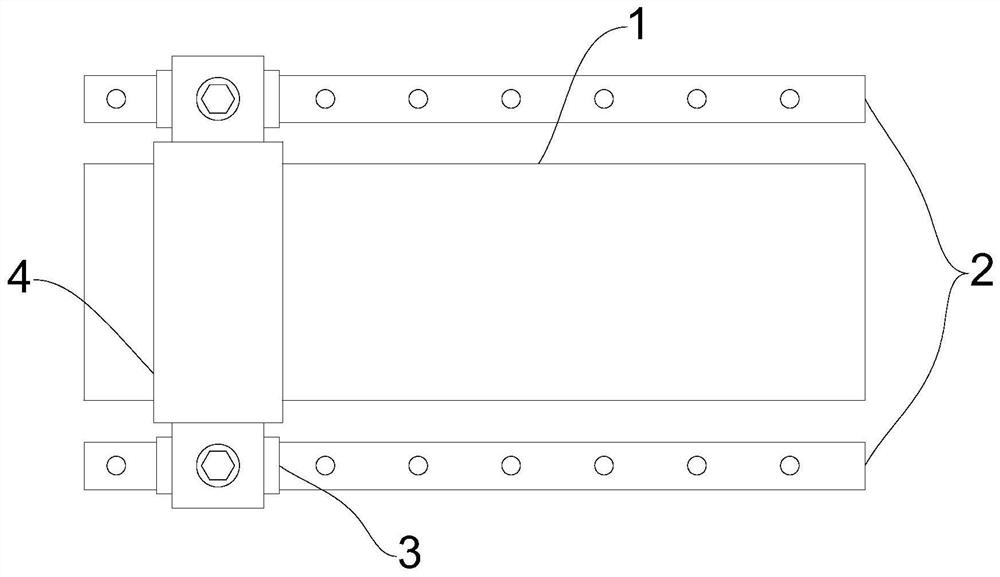

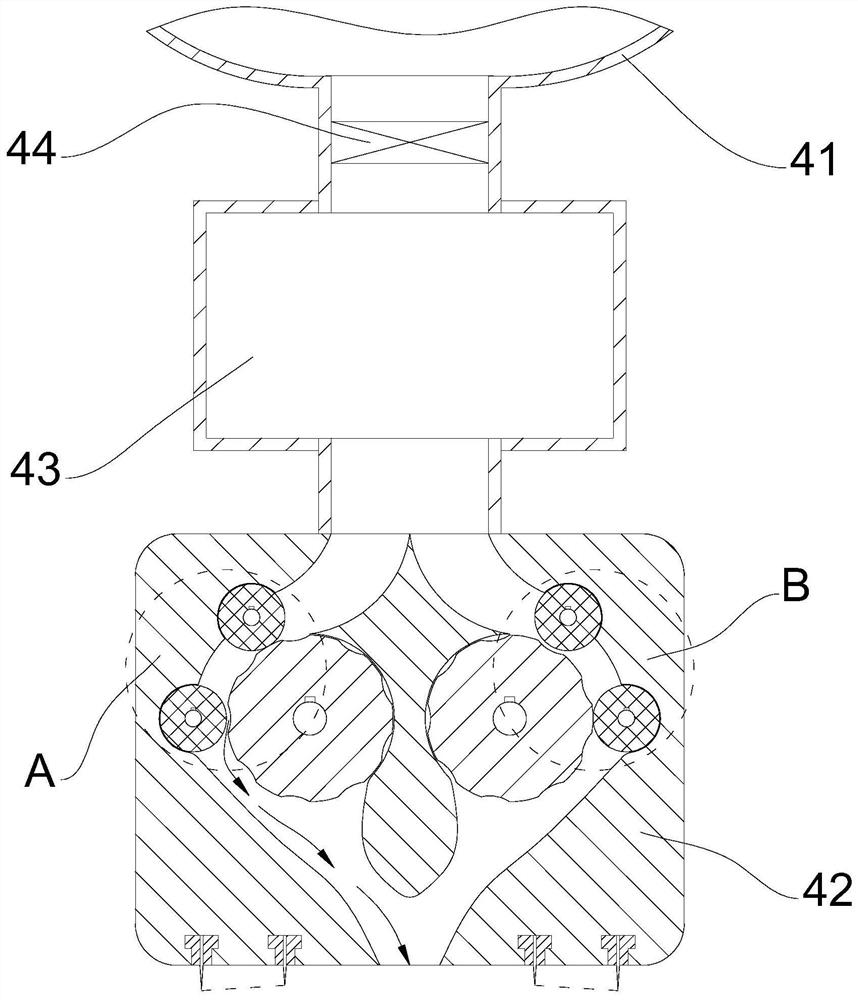

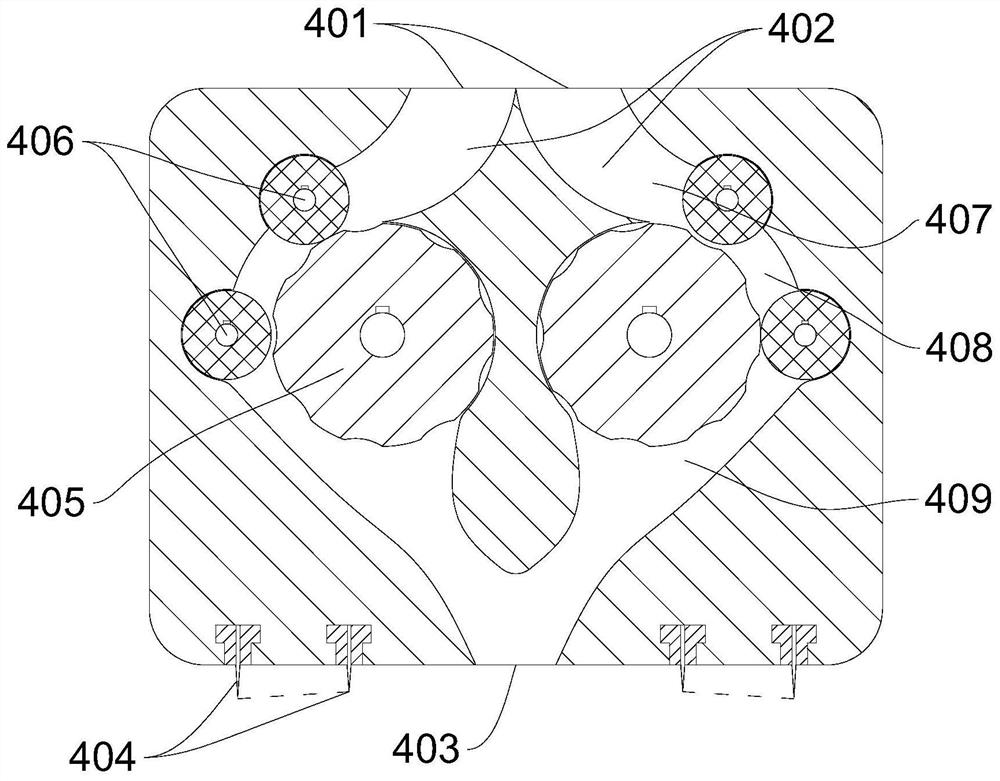

[0025] Embodiment: A powder output device of laser additive equipment, the structure is as follows Figure 1 to Figure 5 As shown, it includes a pair of guide rails 2, and the forming workpiece 1 is located between the guide rails 2 on both sides. 2, the powder outlet mechanism 4 is connected with a linear motor, and the linear motor is used to drive the powder outlet mechanism 4 to move back and forth on a straight line. The powder outlet mechanism 4 includes a storage funnel 41, and the volume of the storage funnel 41 can be stored for The metal powder processed by multiple parts, the storage hopper 41 is connected with a powder outlet module 42, and the powder outlet module 42 includes two powder inlets 401, two flow channels 402 and a powder outlet 403, two powder outlets The material inlet 401 is next to the docking material storage funnel 41 and has the same size, which can ensure the same feeding speed. The two flow channels 402 each correspond to a powder material inle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap