Electric wire connecting assembly and motor with same

A technology for connecting components and electrical connections, which is applied to electric components, components and connections of connecting devices, etc., can solve problems such as unreliable connection and complicated installation process of power cords, achieve reliable electrical connection and wire fixation, and avoid mistakes. , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040]

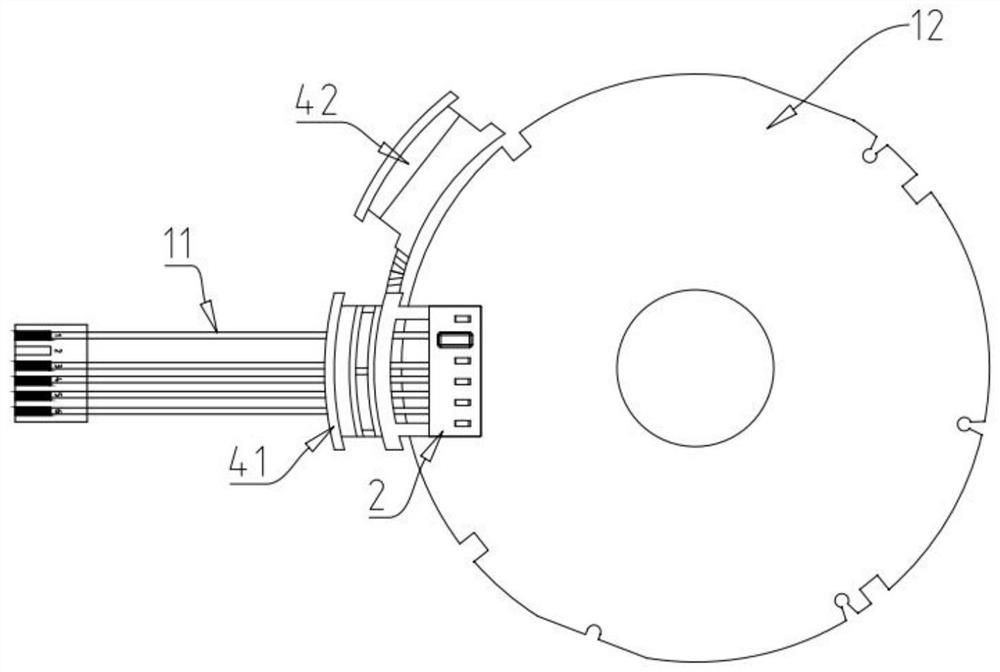

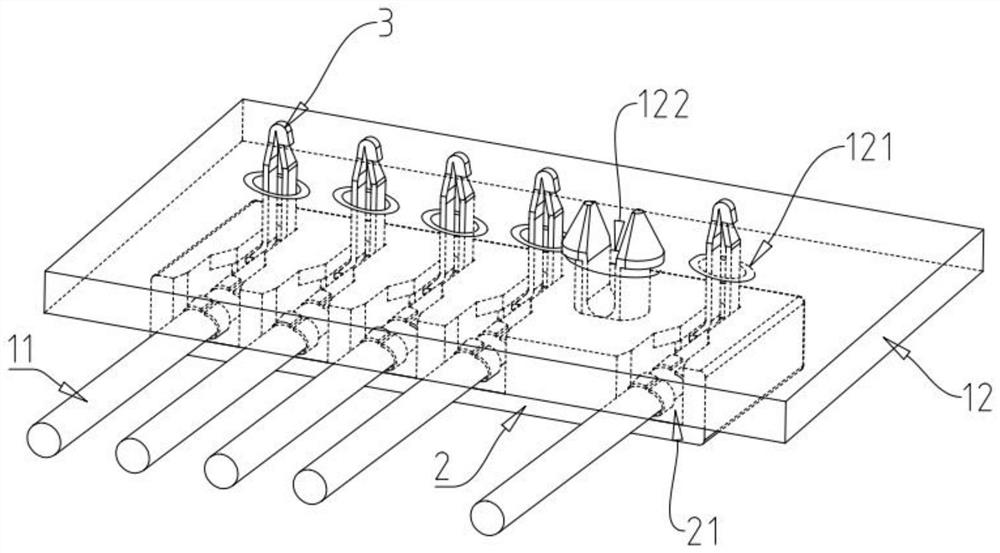

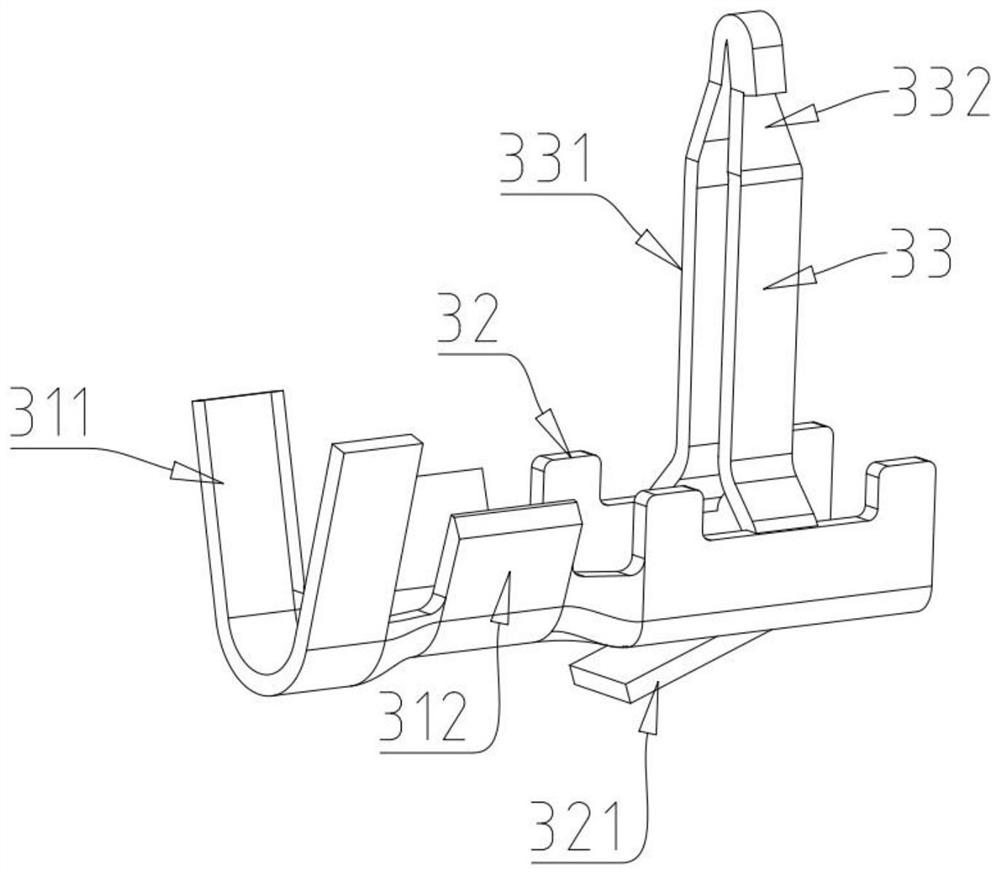

[0041] like Figure 1a and Figure 1b As shown, the wire connection assembly provided by this embodiment includes a power cord 11, a control board 12, a connection terminal 3, a fixed shell 2 and an outlet clip 4; the connection terminal 3 has a crimping end 31 and a plugging end 33, and the crimping end 31 Used to fasten the power cord 11 and electrically connect with the power cord 11; the plug end 33 is electrically connected to the control board 12; the fixed shell 2 has a mounting groove 21, and the connecting terminal 3 can be fixed in the mounting groove 21, and the fixed shell 2 passes through The detachable structure is fixed on the control board 12; the outlet clip 4 has a wire hole through which the power cord 11 is led out to the outside of the motor housing; the connecting terminal 3 is fixedly connected to the fixed shell 2, and the outlet clip 4 is connected to the fixed shell 2 For soft connection, the connection terminal 3, the fixed shell 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com