Breakable capsule sorting device and breakable capsule sorting system

A sorting device, the technology of blasting beads, applied in sorting and other directions, can solve the problem of high cost of blasting beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

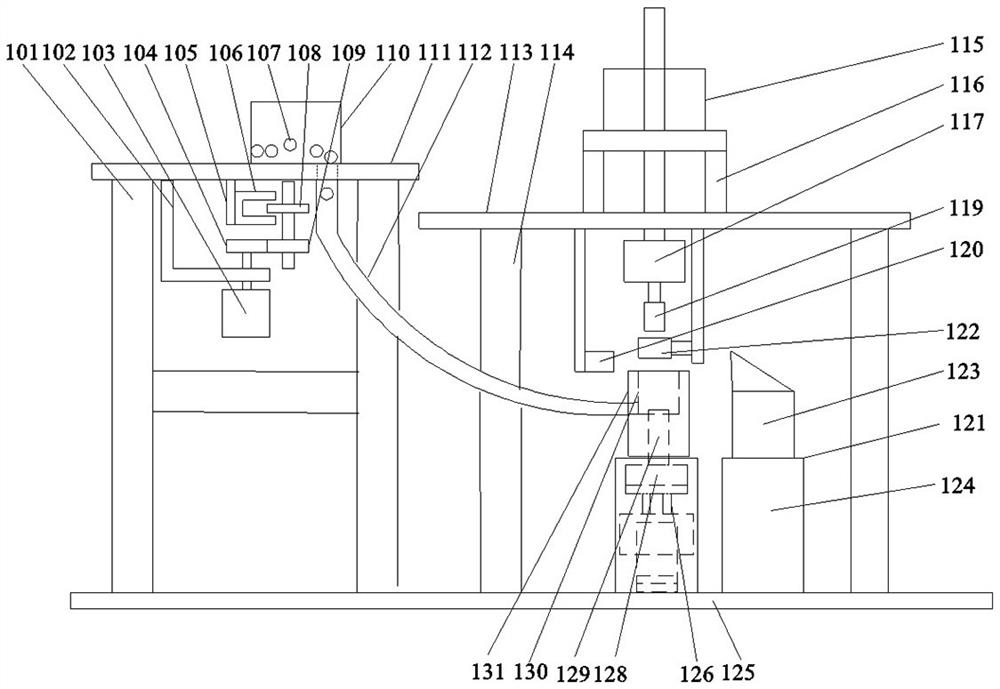

[0065] like Figure 1 to Figure 3 As shown, in this embodiment, the popping bead sorting system mainly includes two parts, namely, the popping bead conveying device and the popping bead sorting device. The bead sorting device sorts the sent popping beads 107, rejects unqualified low-strength popping beads, and recycles the broken popping beads.

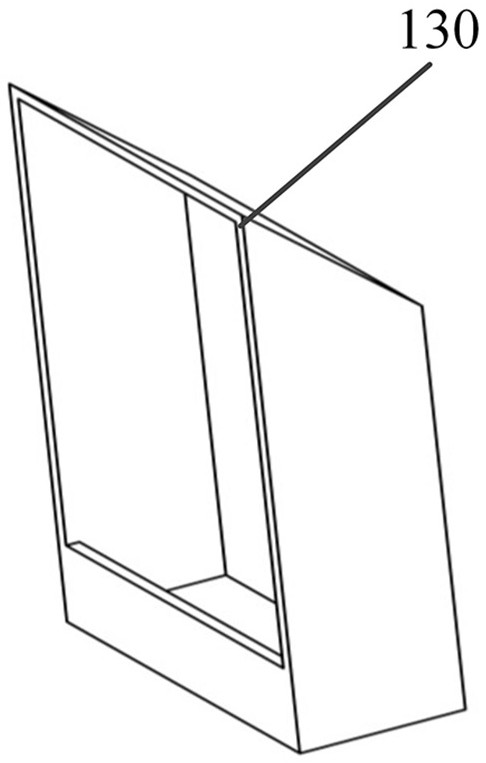

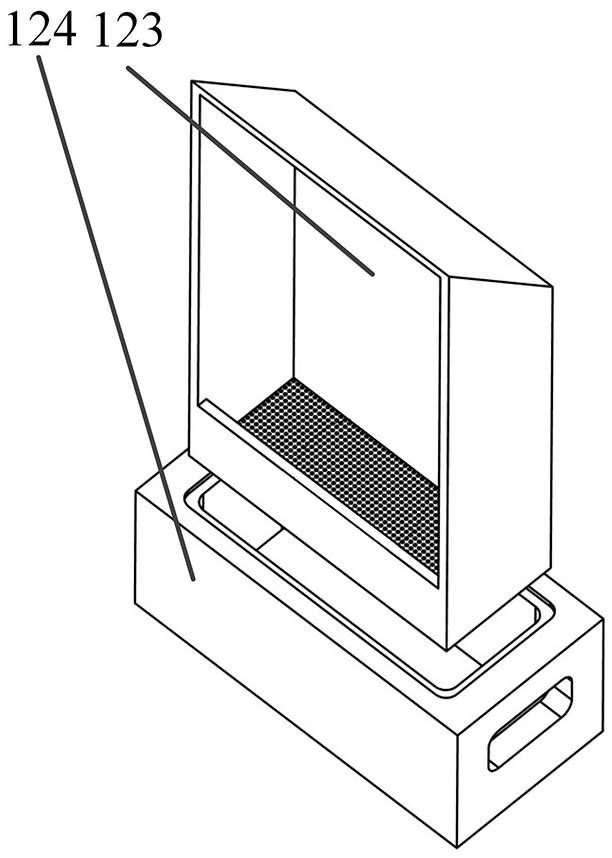

[0066] The explosive bead sorting device comprises a base 125, on which a support platform 129 is set, and the support platform 129 is used to place the explosive beads 107 to be sorted, and a support frame 114 is fixed on the base 125, and a platform 113 is arranged on the top of the support frame 114, and the platform 113 is fixed with a motor mounting seat 116, and a control motor is fixedly installed on the motor mounting seat 116. The control motor specifically adopts a linear motor 115, and the output shaft of the linear motor 115 reciprocates up and down. The rod 119 and the sample pressing rod 119 extend in the up and down di...

Embodiment 2

[0084] It differs from Embodiment 1 mainly in that: in Embodiment 1, the pressure sensor is arranged between the output shaft of the linear motor and the sample pressing rod. In this embodiment, the pressure sensor can also be arranged between the cylinder and the support platform, and can also detect the reverse force when the popping beads are pressed.

[0085] Of course, in other embodiments, pressure sensors can also be provided separately for the sample pressing rod and the support platform, so as to achieve double guarantees and avoid misjudgment when a single pressure sensor fails.

Embodiment 3

[0087] The main difference between it and Embodiment 1 is that in Embodiment 1, automatic control is realized by using a pressure sensor in cooperation with a control unit. In this embodiment, it is possible to identify whether the detonation beads have been crushed by means of photographing and comparison, and then control the operation of the qualified detonation bead collection structure or the broken detonation bead collection structure through the control unit. In this embodiment, since the photographing and comparison here is only whether the popping beads are crushed or not, the requirements for equipment and algorithms are relatively low, and the cost is relatively low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com