Post-cast strip independent support convenient to disassemble

A technology of post-casting strips and supporting feet, which is applied to the preparation and construction of pillars and building components on site, and can solve the problems of disassembly, inconvenient construction, and inability to turn over and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

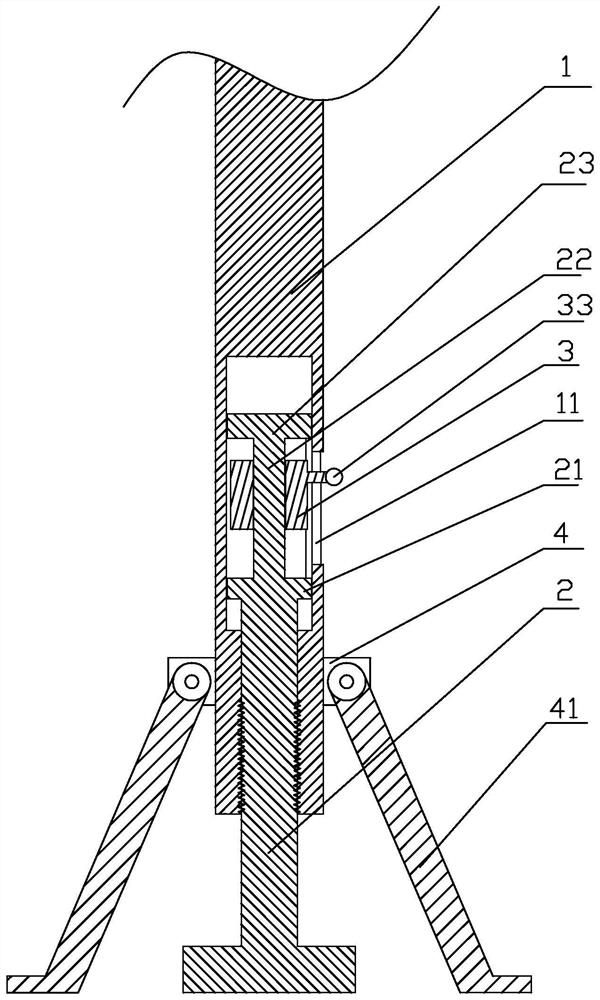

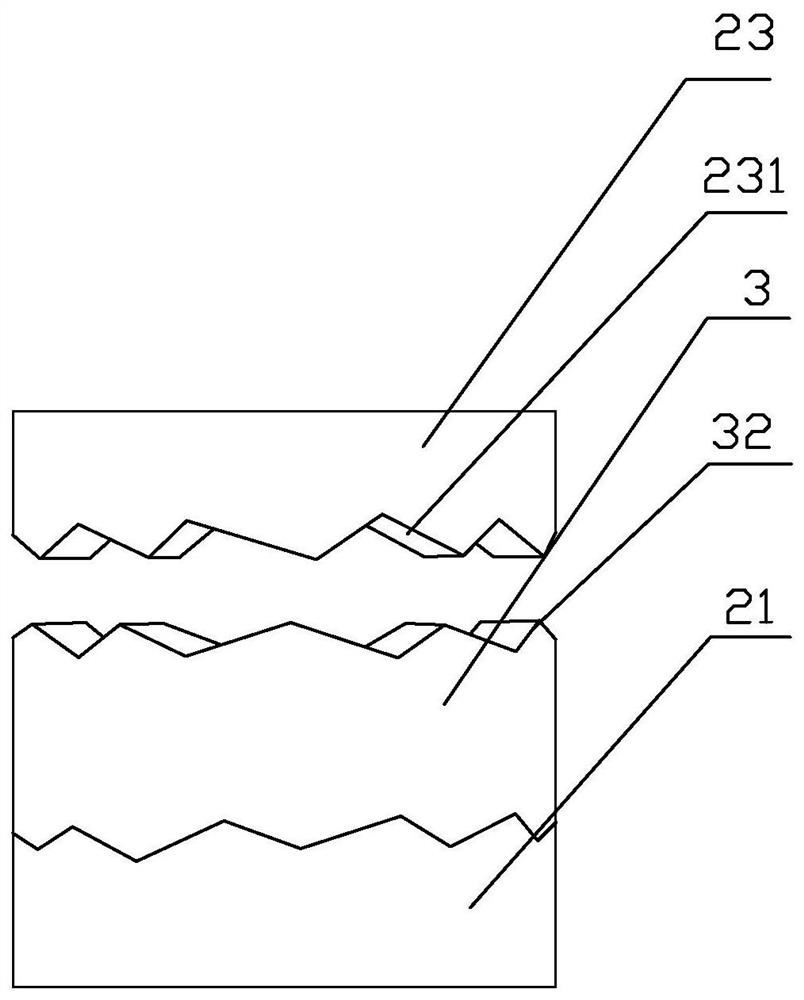

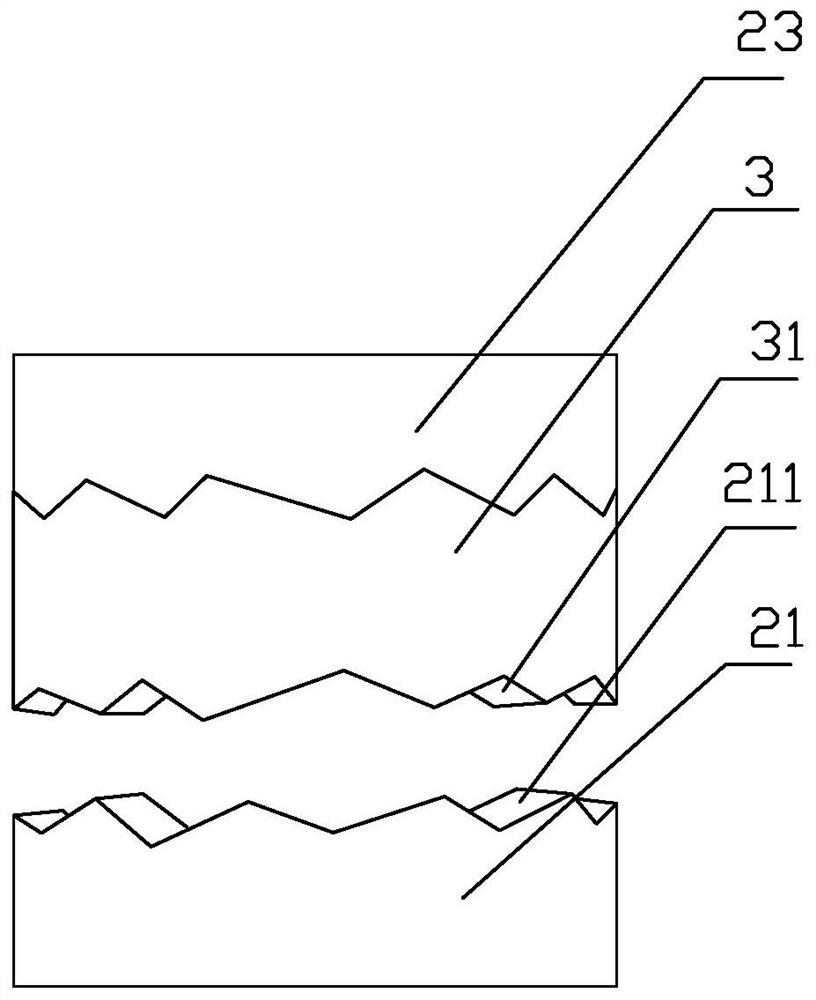

[0017] Embodiments of the independent support of the post-cast tape that is easy to disassemble in the present invention are as follows: Figure 1 to Figure 3 As shown: it includes a cylinder 1, the cylinder 1 is provided with a positioning sleeve 4, and the positioning sleeve 4 is provided with a number of supporting feet 41 along the circumference, and one end of the supporting feet 41 is swingably connected to the positioning sleeve 4, and the other A number of anti-slip strips are evenly distributed on the end surface of one end, and one end of the cylinder 1 is provided with a thread to cooperate with a conflicting member 2, and one end of the conflicting member 2 is formed with a conflicting head, and the other end is an extension end extending into the cylinder 1, The extension end of the collision member 2 is provided with a rotating disk 21, and the end of the rotating disk 21 facing away from the collision head is evenly distributed with a number of first helical teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com