Accurate crop picking device

A crop and precise technology, applied in the fields of picking machines, agriculture, agricultural machinery and implements, etc., can solve the problems of skewed dumping of crops, large picking losses, and precise picking of difficult crops, so as to ensure the accuracy and improve the effect of picking and harvesting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

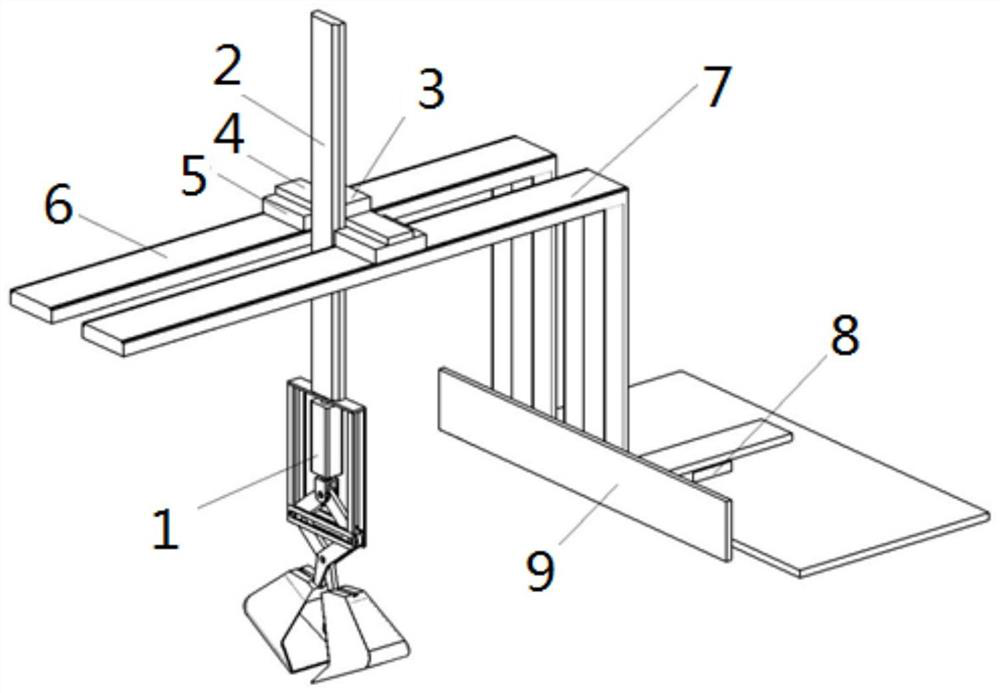

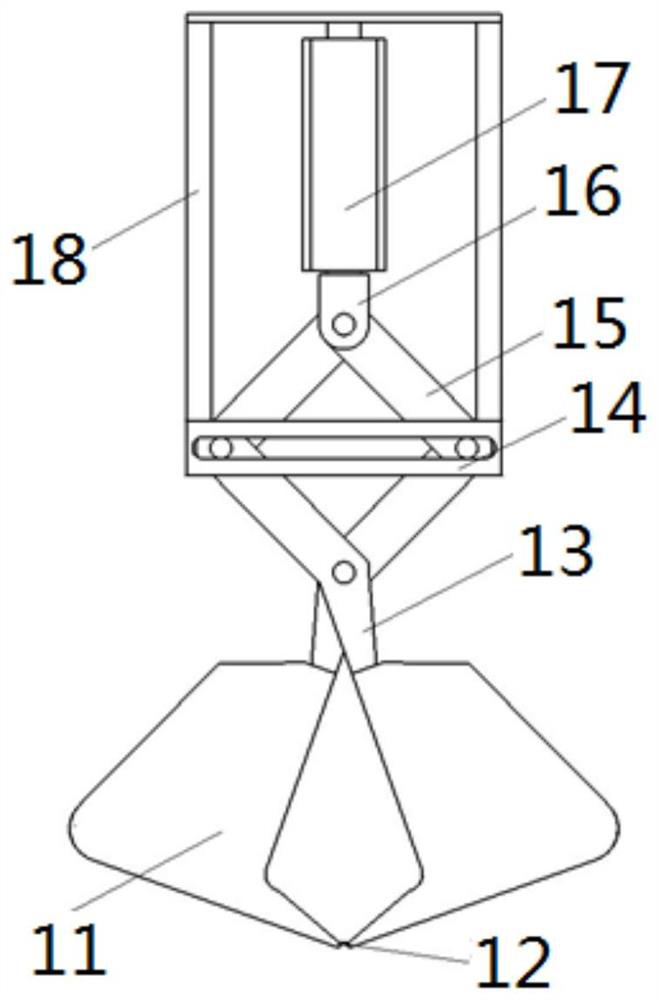

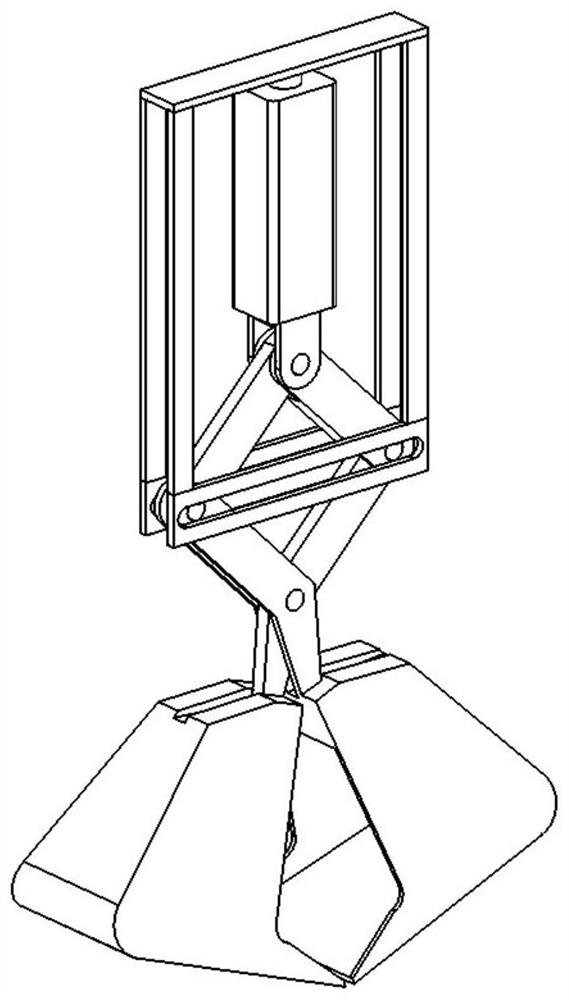

[0030] Such as figure 1 As shown, a precision picking device for crops includes a fixed bracket 8 on which a translational drive mechanism and a push plate correction mechanism 9 that can be pushed out and retracted are installed, and the push plate correction mechanism 9 is arranged at a position facing the root of the crop or the branch of the crop , the translation drive mechanism is connected with a vertical movement mechanism 2, and the bottom of the vertical movement mechanism 2 is equipped with a picking storage mechanism 1, wherein the translation drive mechanism includes a guide rail 7 and a linear motor 6, and the guide rail 7 is equipped with a movable mechanism for connecting the vertical movement mechanism 2. Move the supporting part, the supporting part is connected with the linear motor 6, and the linear motor 6 makes the supporting part move horizontally on the guide rail 7 after being powered on, thereby driving the vertical moving mechanism 2 to move horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com