Load sensor fast to install and using method thereof

A load sensor, fast technology, applied in the field of communication, can solve problems such as single detection data, difficult to work effectively, unable to be affected by heavy objects and effective detection of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the implementation of the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further elaborated below in conjunction with specific embodiments.

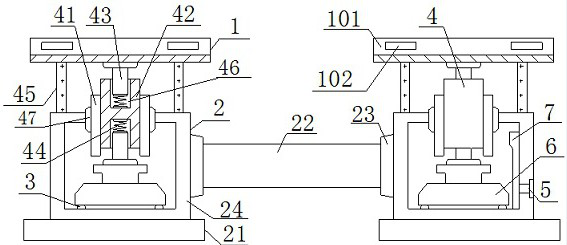

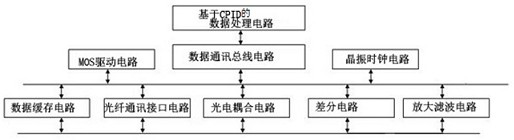

[0022] Such as figure 1 and 2 A fast-installed load sensor is shown, including a connecting cutting board 1, a load-bearing keel 2, a guide rail 3, a load-bearing column 4, a terminal 5, a load sensor 6, and a drive circuit 7, wherein the load-bearing keel 2 is rectangular in cross section. Columnar frame structure, its upper end surface is connected with at least one connecting cutting board 1 through the bearing column 4, the lower end surface and the upper end surface of the connecting cutting board 1 are distributed parallel to the axis of the bearing keel 2, and the number of load sensors 6 is connected to the upper end surface of the bearing keel 2 The number of connecting chopping boards 1 is the same, and each load sensor 6 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com