Wet type electric photographic printing machine having liquid carrier recovery apparatus

A technology of liquid carrier and wet electricity, which is applied in the application of electric recording technology of charge pattern, equipment and printing of electric recording process of application of charge pattern, and can solve the problems of reducing the recovery efficiency of liquid carrier and the inability of liquid carrier to be fully removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

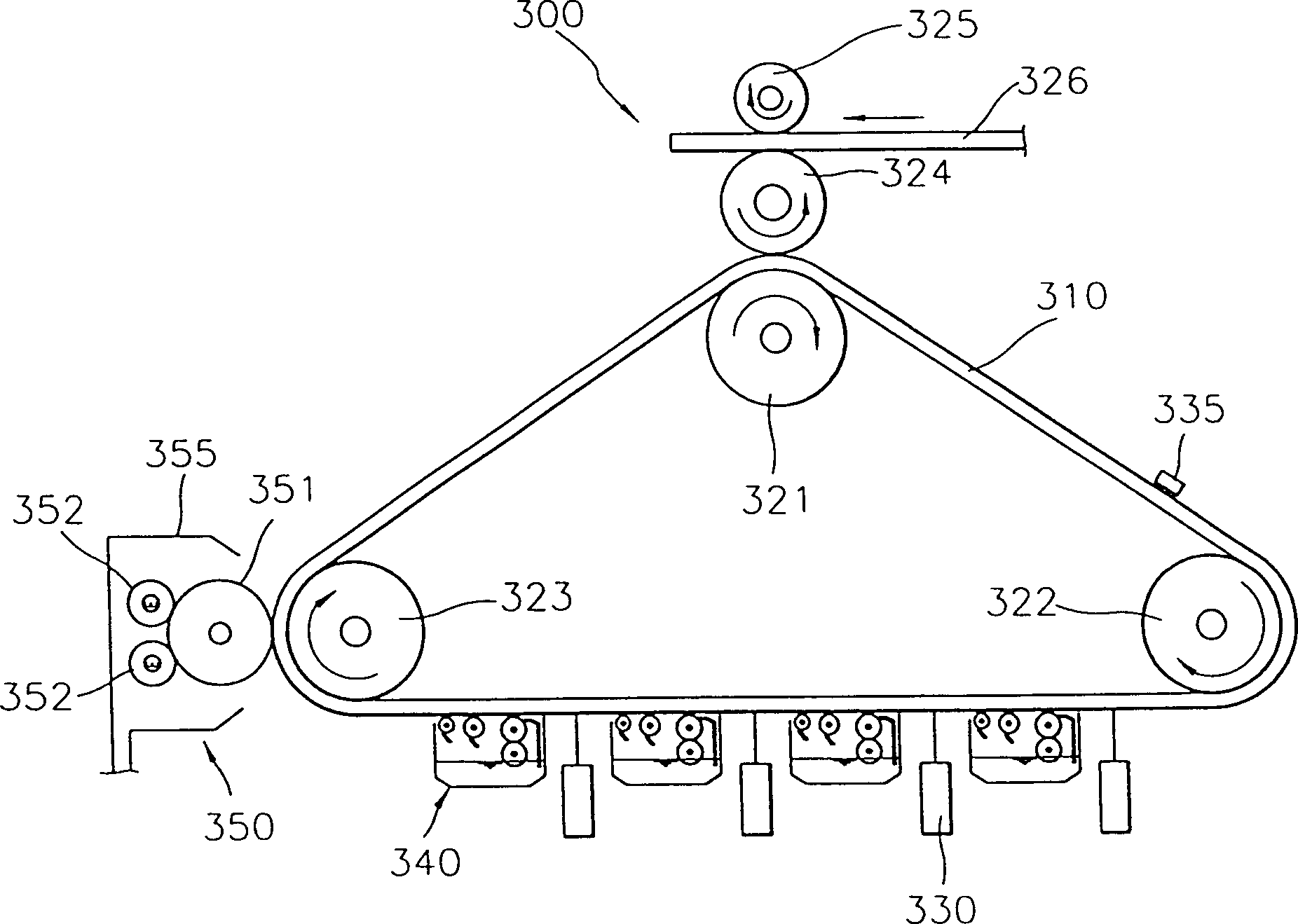

[0020] refer to figure 2 , The wet laser printer 300 according to the embodiment of the present invention includes a supporting roller 321 for supporting the photosensitive belt 310 , a regulating roller 322 and a driving roller 323 . The driving roller 323 drives the photosensitive belt 310, and the regulating roller 322 adjusts the tension of the photosensitive belt 310 to prevent the photosensitive belt 310 from deviating from its circular track.

[0021] The surface of the photosensitive belt 310 is uniformly charged by the main charger 335 . A laser scanning unit (LSU) 330 is installed on the downstream side of the photosensitive belt 310 to irradiate a laser beam on the photosensitive belt 310 according to an image signal to form an electrostatic latent image. The developing device 340 is used to apply a developing solution containing a mixture of toner of a predetermined color and a liquid carrier on the electrostatic latent image to develop it. In a color printer, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap