Positioning structure of embedded hardware in injection molding die

A technology of injection molding and positioning structure, applied in the field of injection molding, can solve the problems of limited function of hardware, offset, movement, and product size difference of hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

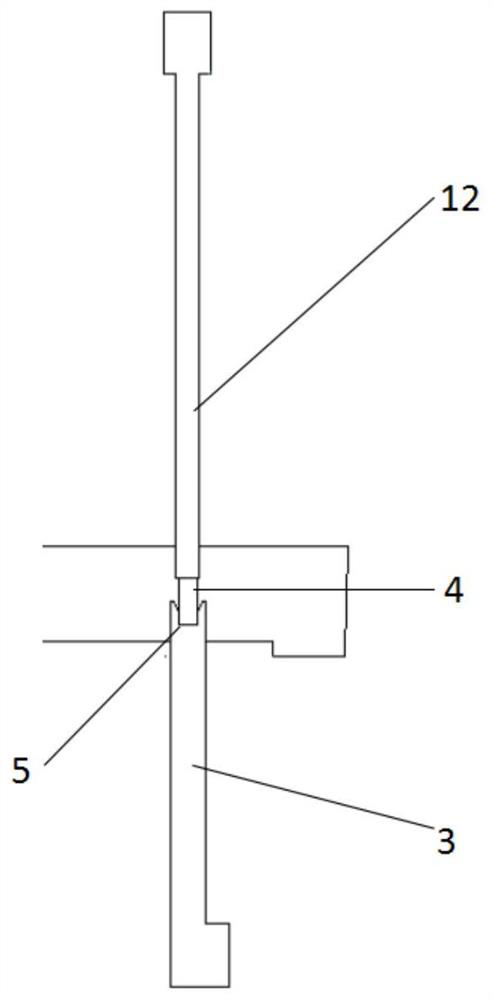

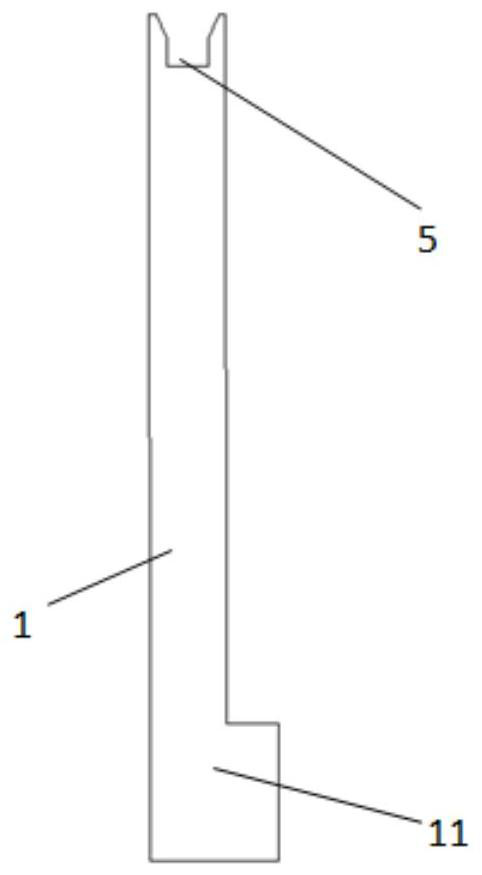

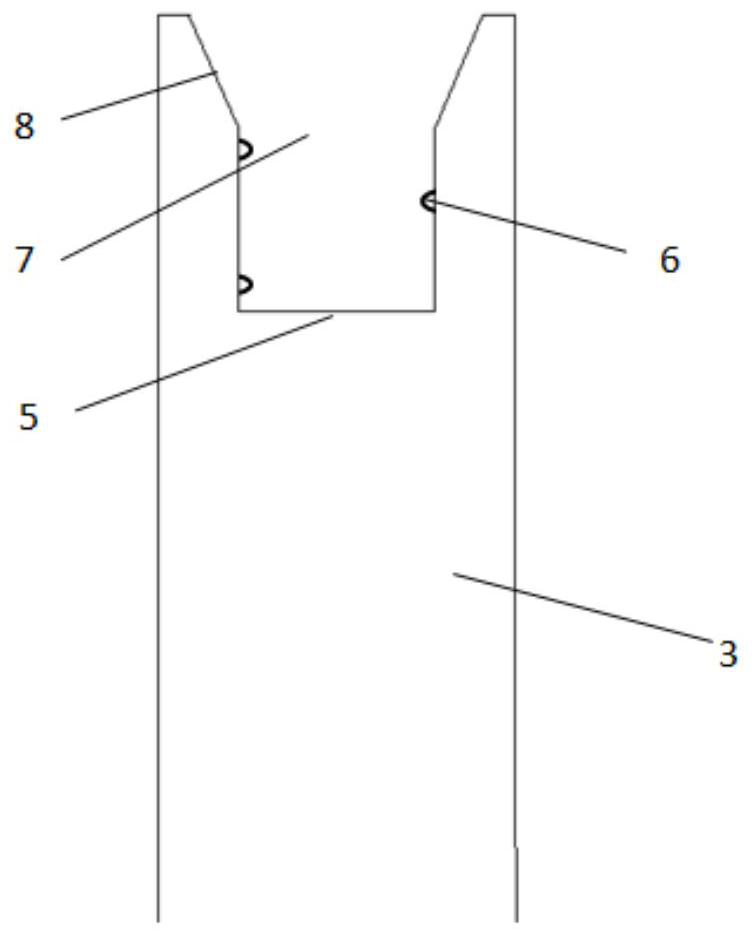

[0040] see figure 1 , the positioning structure of the inlaid hardware in the injection molding mold of the present invention includes a plurality of positioning parts composed of insert pins 12 and inserts 3, and one end of each positioning part is a fixed end 1 fixedly connected with the mold body of the mold , and the other end is the positioning end that is in contact with the hardware set in the mold cavity 2 of the mould. When the fixed end 1 fixes the positioning member to the core of the mold, the positioning end extends into the mold cavity 2 . In this embodiment, each hardware piece is equipped with one setting pin 12 and one setting piece 3 . The fixed end 1 of the insert pin 12 is fixed to the front mold core 14 of the mould, and the fixed end 1 of the insert 3 is fixed to the rear mold core 13 of the mould. Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com