Assembly control method of electric power steel strand

A technology for assembly control and steel strands, which is used in comprehensive factory control, overhead line/cable equipment, towers, etc., which can solve the problem of poor clamping and fixing effect of steel strands, cumbersome and inconvenient operation, and easy fatigue when holding clamps. problem, to achieve the effect of good fixing effect, saving manpower and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

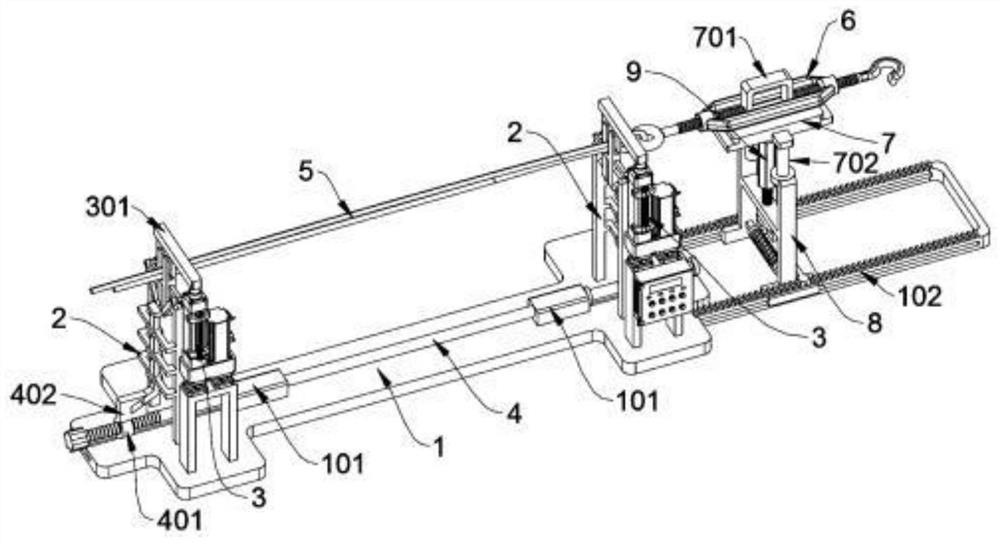

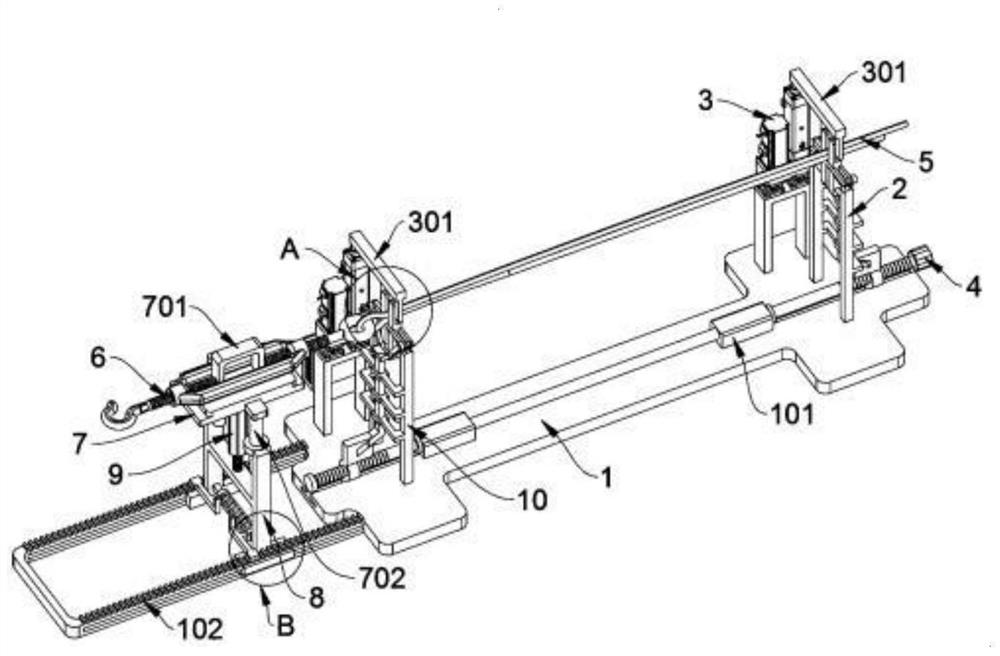

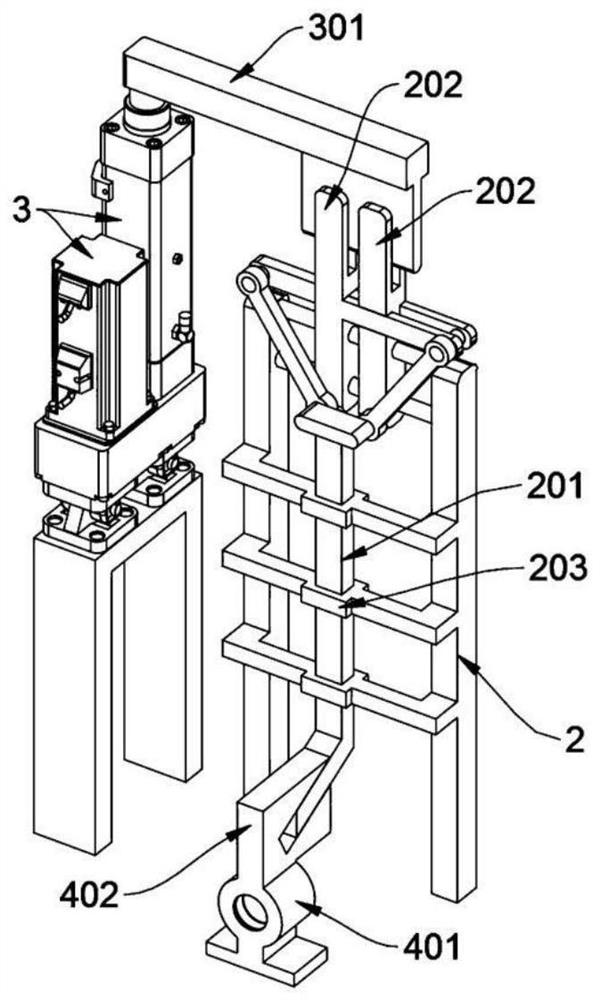

[0031] see Figure 1 to Figure 10 , an embodiment provided by the present invention: an assembly control method for electric steel strands, the method is implemented based on an assembler, the assembler includes a base plate 1, a steel strand 5 and an installation pallet 7, the base plate 1. It is arranged in an I-shape as a whole, and two support frames 2 are symmetrically supported and welded on the front and rear ends of the two support frames 2. Two electric push rods 3 are also symmetrically supported on the right side of the two support frames 2, and the base plate 1 There is a double-ended threaded rod 4 installed in the middle position in the left and right d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com