Connection rod type wire winding device

A wire winder and connecting rod type technology, applied in the field of connecting rod type wire winders, can solve the problems of short service life, inconvenient installation, complex structure of elastic clamping body, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

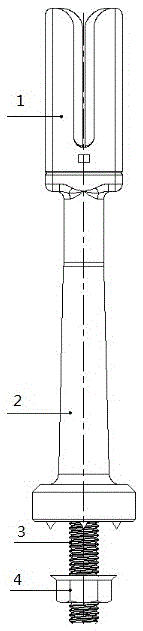

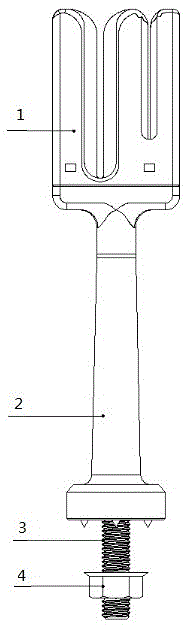

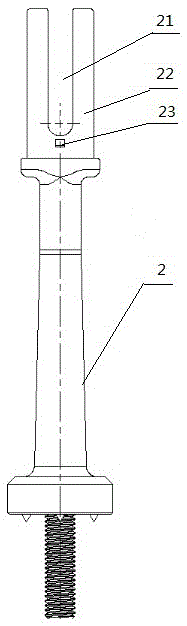

[0022] From figure 1 , figure 2 It can be seen from the figure that a connecting rod type wire winder includes a body 2. The lower part of the body 2 is provided with a screw 3 for installing it on the workbench. The screw 3 and the nut 4 cooperate to fix the body 2. effect. The body 2 of the present invention is the most basic structural part of the product, and its surface is required to be free of depressions, trachoma, air bubbles, and burrs, with a smooth surface and stable dimensions; the outer surface of the product must be treated by EDM discharge to achieve uniform appearance; Elastic rectangular support 22. The material of the screw 3 is A3, the extension length is 28 mm, and it is injected out of the mold together with the body.

[0023] The feature of the present invention is: the upper part of the body 2 is equipped with an elastic extrusion sleeve 1, the elastic extrusion sleeve 1 has an integral structure, and is fastened on each pillar on the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com