Manual argon tungsten-arc welding efficient welding combined device capable of automatically feeding fine welding wires and method

A technology of argon tungsten arc welding and combined device, which is applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of low welding efficiency of thin wire, improve welding production efficiency, improve welding seam quality and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The invention relates to a high-efficiency welding combination device for manual tungsten argon arc welding with automatic feeding of fine welding wire.

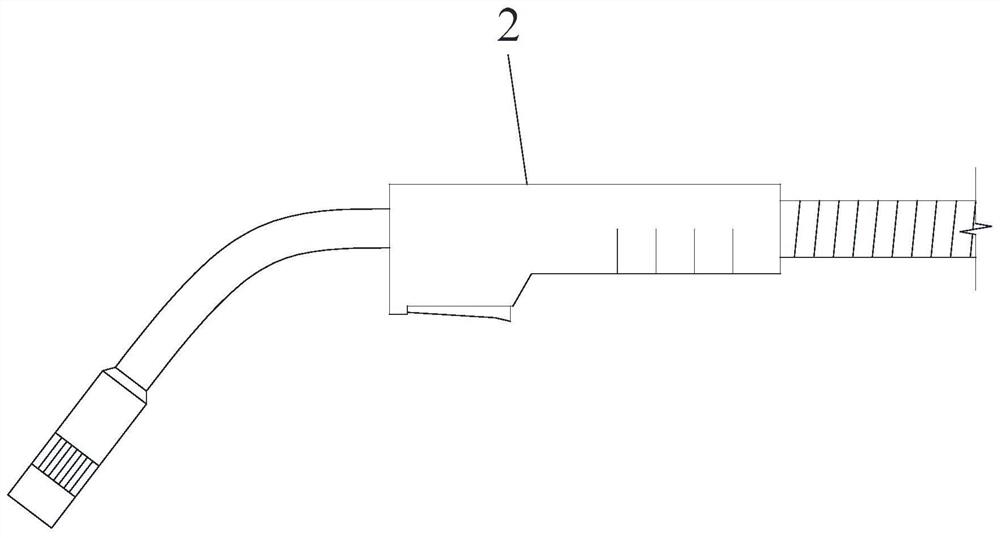

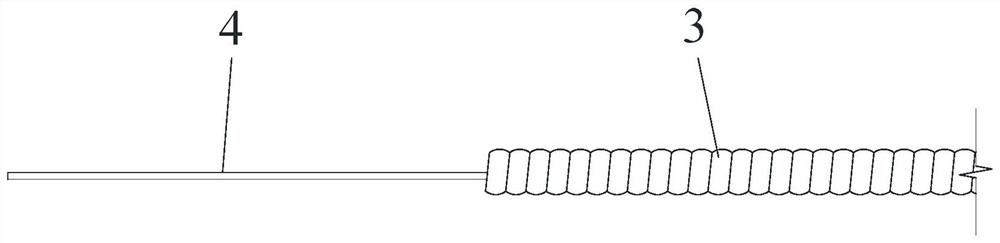

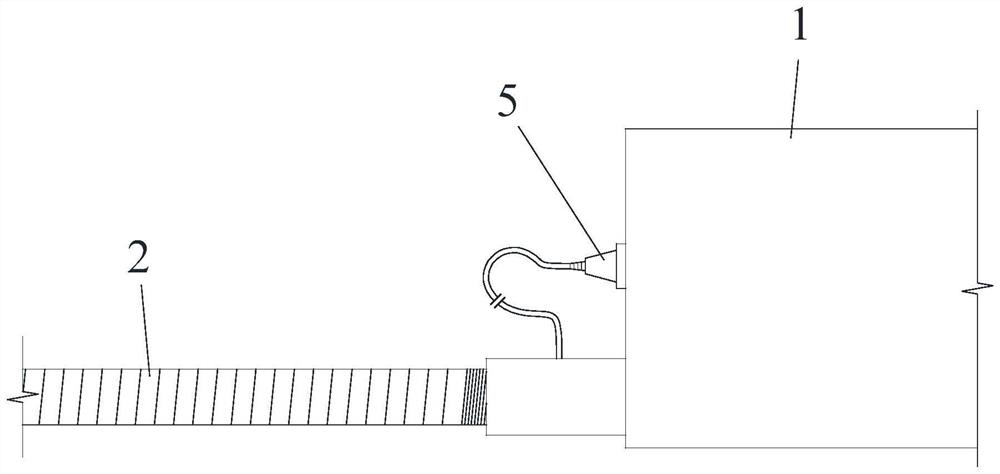

[0034] Using an ordinary semi-automatic CO 2 Gas shielded welder 1 (MAG welder), dismantled as figure 1 2 heads of the welding torch shown, retain the wire feeding hose 3, the wire feeding hose 3 is as figure 2 Bellows shown; as image 3 and 4 As shown, pull out the finger-pressed switch terminal 5 on the head of the original welding torch 2 from the welding machine, and at the same time connect a Figure 4 The foot controller 6 shown; the semi-automatic CO 2 The ground wire of the gas shielded welding machine 1 is not connected with the workpiece to be welded, so that the semi-automatic CO 2 The gas shielded welding machine 1 does not form a welding current loop.

[0035] The semi-automatic CO 2 The gas shielded welding machine 1 includes a wire feeder, and the semi-automatic CO 2 4 discs of thin welding wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com