PE plate lining channel

A PE board and lining technology, applied in the field of medium and small channel lining in irrigation areas, can solve problems such as poor adaptability to foundation deformation, long construction period, and poor frost heave resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

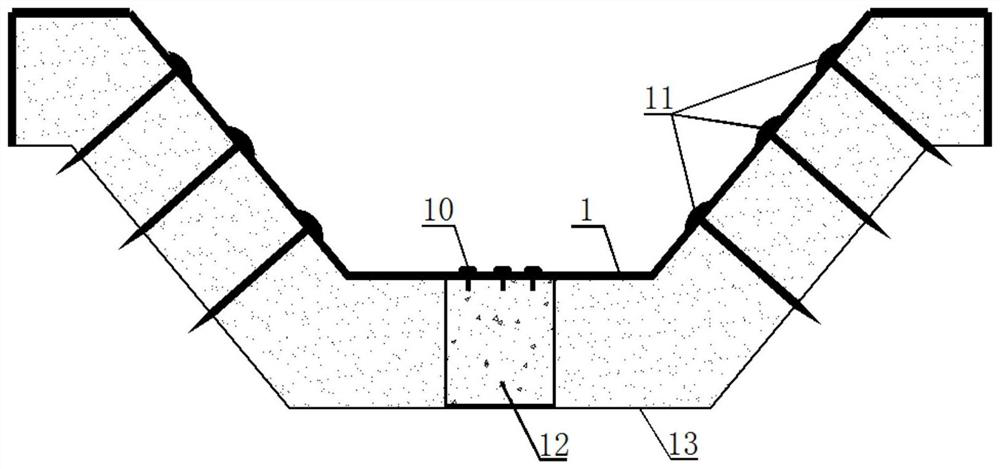

[0022] The present invention provides a PE board lining channel. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

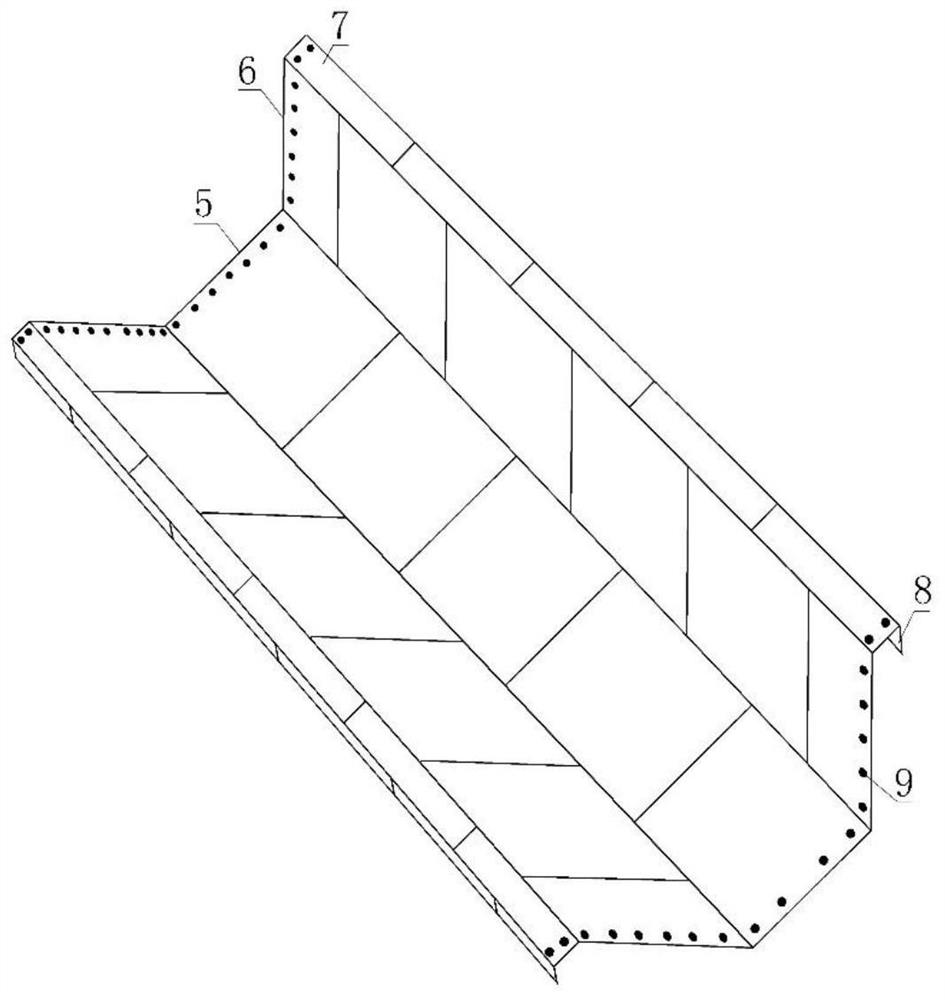

[0023] The implementation process can be divided into: soil foundation forming, pouring (or prefabricated installation) tooth wall and pier, cushion laying, prefabricated PE plate installation, each part will be explained below.

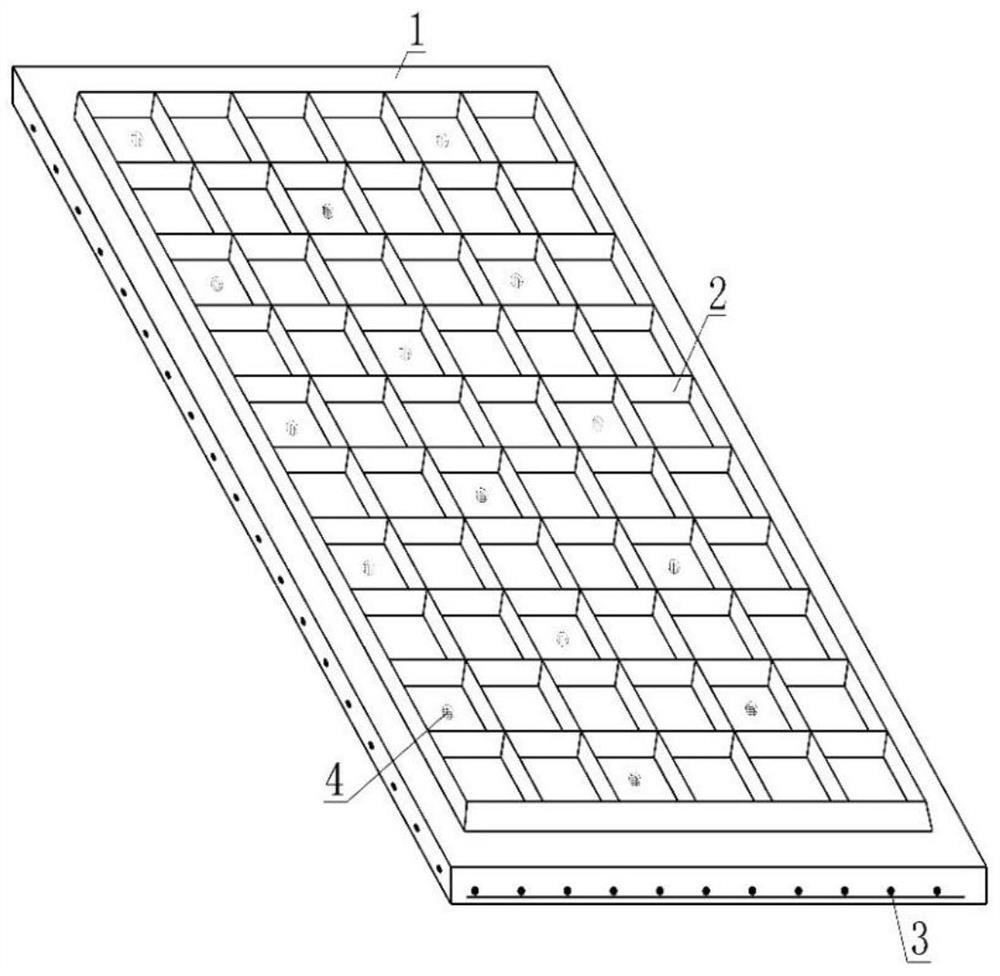

[0024] see figure 1 It is a structural schematic diagram of the plate of the present invention, as a small unit of the lining, the plates are tightly connected by hot-melt connection, the back surface is provided with ridges (protrusions) 2 intersecting horizontally and vertically, and steel wire mesh sheets 3 are arranged inside , according to the strength calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com