Starting and braking time sequence control method for hoisting frequency converter

A control method and braking sequence technology, applied in the direction of program control, computer control, general control system, etc., can solve the problem of step process without frequency, and achieve the effect of preventing the hook from slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

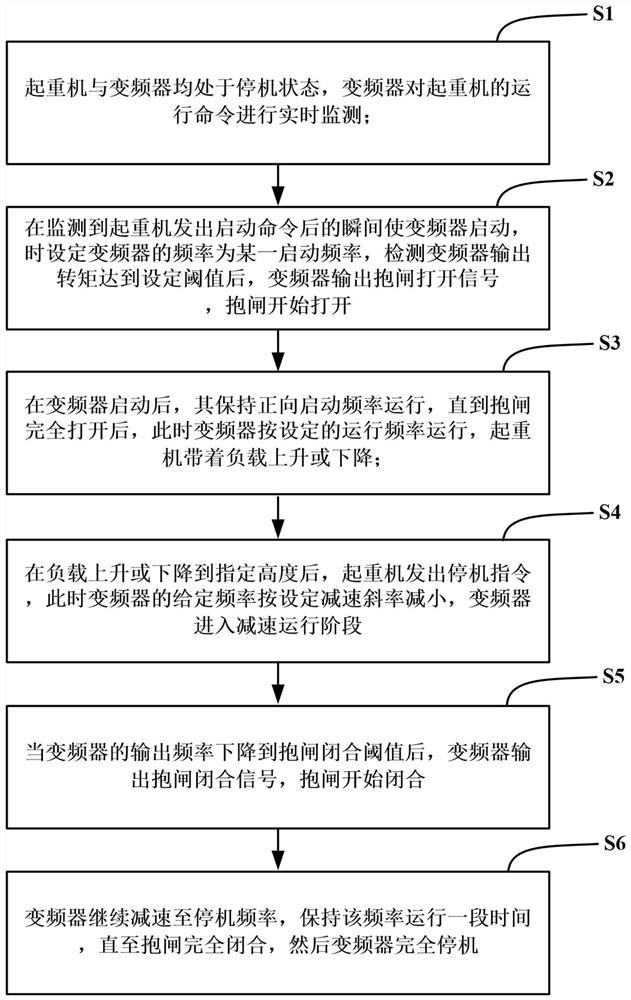

[0035]The first embodiment of the present invention includes the following steps:

[0036]S1: Both the crane and the inverter are in a downtime, and the inverter monitors the running command of the crane. When the crane is monitored, the S2 phase is performed after the start command input is input;

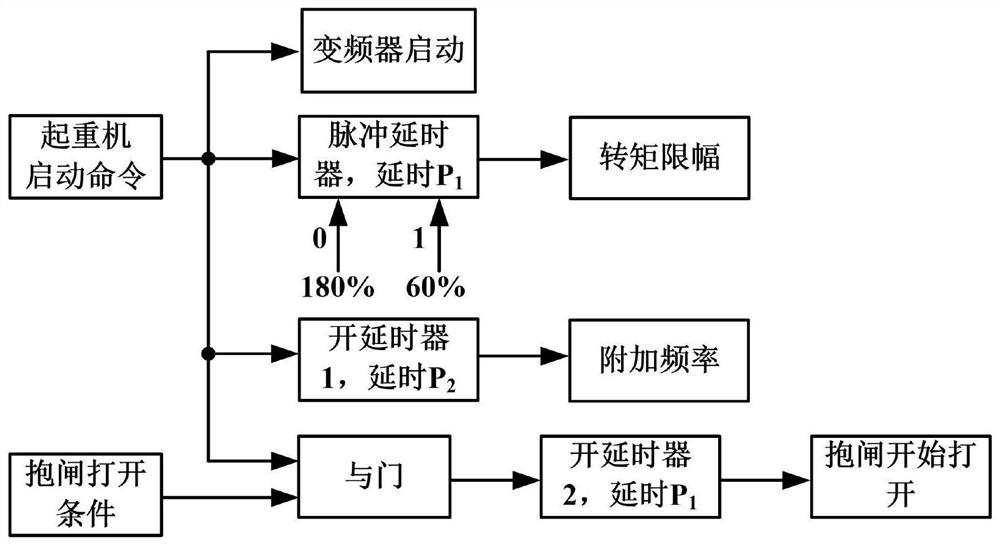

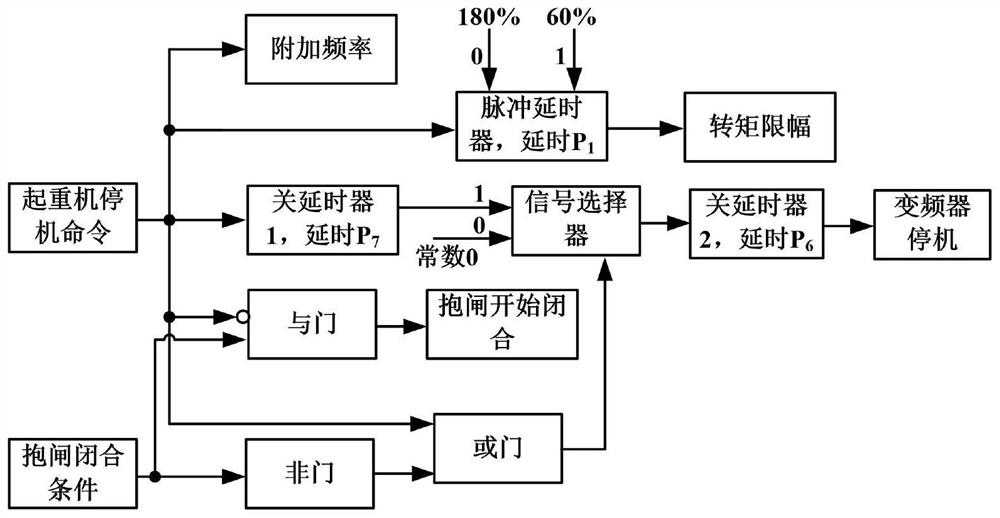

[0037]S2: When the instant drive after the crane is issued, the instant drive starts running, at which point the frequency of the inverter is a certain start frequency, and the torque limit of the drive is set to verify the torque value. The inverter runs to the start frequency, and detects the output torque value of the inverter. When the torque value reaches the set verification value and holds the set time, the torque limit value is set to the default value of the drive. . In the present invention, the value of the validation torque is 60%, and the time is set to 0.5 s. When the torque value reaches the set verification value and holds the set time, the torque limit is set to 180%, while d...

no. 2 example

[0050]The second embodiment of the present invention includes the following steps:

[0051]S1: Both the crane and the inverter are in a downtime, and the inverter performs real-time monitoring of the running command of the crane. Monitor the crane after the start command input is executed after the start command input;

[0052]S2: When the instant drive after the crane is issued, the active frequency converter is started, the frequency of the inverter is set to a certain boot frequency, and then the drive is a torque limit to generate the verification torque, detect the frequency conversion. After the output torque reaches the validation torque, the limit is changed, the inverter output torque rises, when the output torque is greater than the brake open threshold, all the conditions that open the brake are satisfied, the inverter output hug The gate opens the signal, the verification torque phase lasts 0.5 s, can be changed according to the actual situation;

[0053]S3: After the inverter is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com