Travelling crane variable-frequency speed regulation control system special for pipe pile

A frequency conversion speed regulation and control system technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of 45kw damage to the main hook, equipment can not work, affecting the orderly operation of pipe piles, etc., to improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

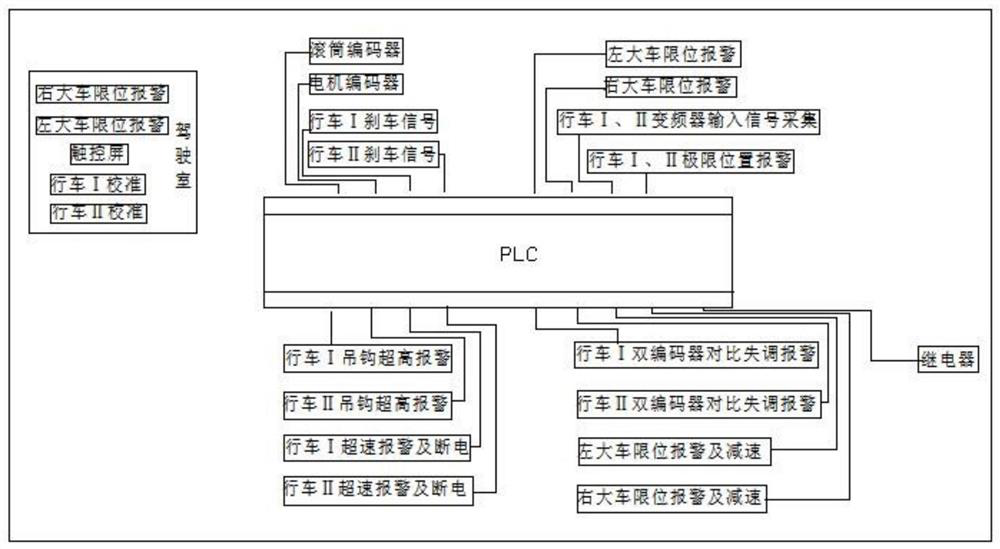

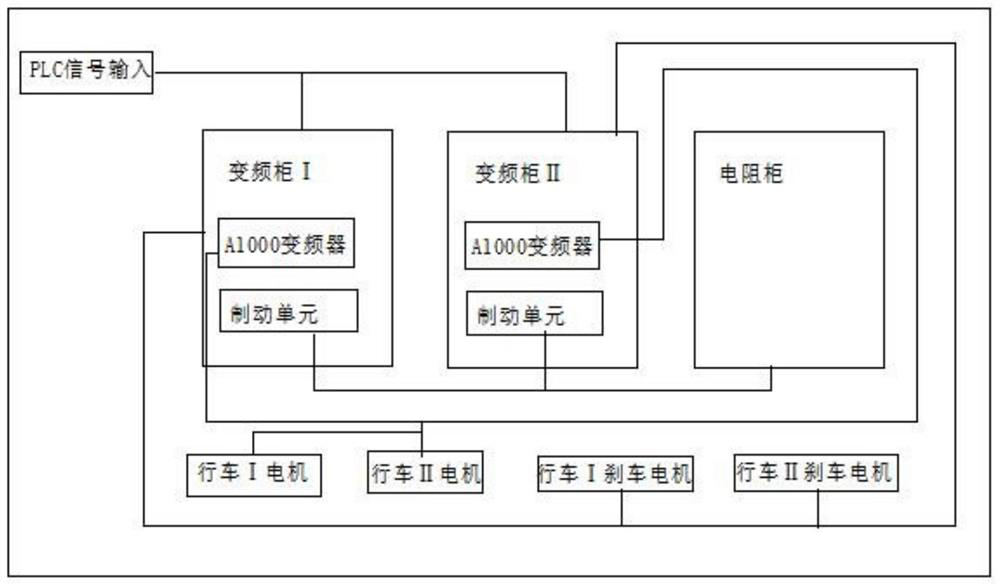

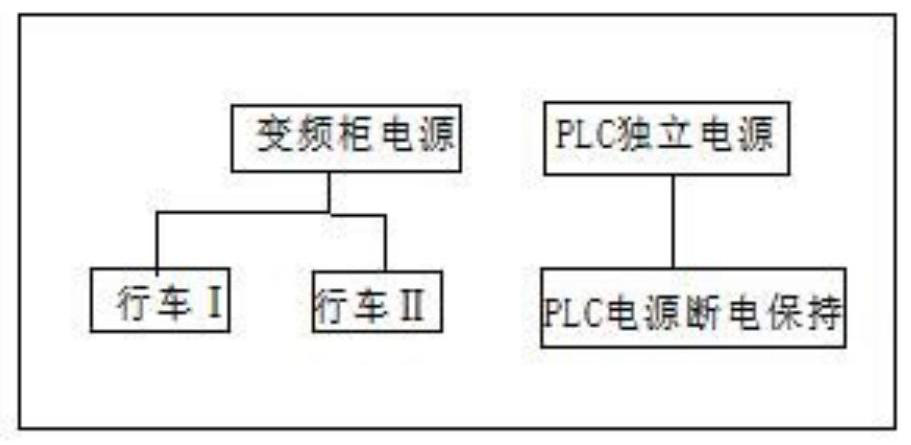

[0017] Embodiment 1, a driving frequency conversion speed regulation control system dedicated to pipe piles. The driver’s cab is equipped with a left cart limit alarm, a right cart limit alarm and a display screen, and is also equipped with a driving I calibration and a driving II calibration. The above-mentioned device Connect to the PLC through a data line; the upper port of the PLC is connected to the signal input of the driving Ⅰ, the signal input of the driving Ⅱ, the limit alarm of the left cart, the limit alarm of the right cart, and the input signal collection of the inverters of the driving Ⅰ and Ⅱ. Ⅰ, Ⅱ limit position alarm; the lower port of the PLC is sequentially connected to the over-height alarm of the crane I and the hook, the over-height alarm of the crane II, the overspeed alarm and power failure of the vehicle I, the overspeed alarm and power failure of the vehicle II, and the overspeed alarm and power failure of the vehicle II. Double encoder comparison imba...

Embodiment 2

[0018] Embodiment 2, a driving frequency conversion speed regulation control system dedicated to pipe piles, the driver's cab is equipped with a left cart limit alarm, a right cart limit alarm and a display screen, and is also equipped with a driving I calibration and a driving II calibration, the above-mentioned device Connect to the PLC through a data line; the upper port of the PLC is connected to the signal input of the driving Ⅰ, the signal input of the driving Ⅱ, the limit alarm of the left cart, the limit alarm of the right cart, and the input signal collection of the inverters of the driving Ⅰ and Ⅱ. Ⅰ, Ⅱ limit position alarm; the lower port of the PLC is sequentially connected to the over-height alarm of the crane I and the hook, the over-height alarm of the crane II, the overspeed alarm and power failure of the vehicle I, the overspeed alarm and power failure of the vehicle II, and the overspeed alarm and power failure of the vehicle II. Double encoder comparison imba...

Embodiment 3

[0019] Embodiment 3, a driving frequency conversion speed regulation control system dedicated to pipe piles. The driver’s cab is equipped with a left cart limit alarm, a right cart limit alarm and a display screen. In addition, it is equipped with a driving I calibration and a driving II calibration. The above-mentioned device Connect to the PLC through a data line; the upper port of the PLC is connected to the signal input of the driving Ⅰ, the signal input of the driving Ⅱ, the limit alarm of the left cart, the limit alarm of the right cart, and the input signal collection of the inverters of the driving Ⅰ and Ⅱ. Ⅰ, Ⅱ limit position alarm; the lower port of the PLC is sequentially connected to the over-height alarm of the crane I and the hook, the over-height alarm of the crane II, the overspeed alarm and power failure of the vehicle I, the overspeed alarm and power failure of the vehicle II, and the overspeed alarm and power failure of the vehicle II. Double encoder comparis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com