Spacing-adjustable corn stripping and ear picking header

An adjustable, comb-off technology, applied in the direction of headers, harvesters, external crop dividers, etc., can solve the problems of poor adaptability, inconvenient operation, heavy weight, etc., to enhance the adaptability of row spacing, suitable for wide promotion, effect significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

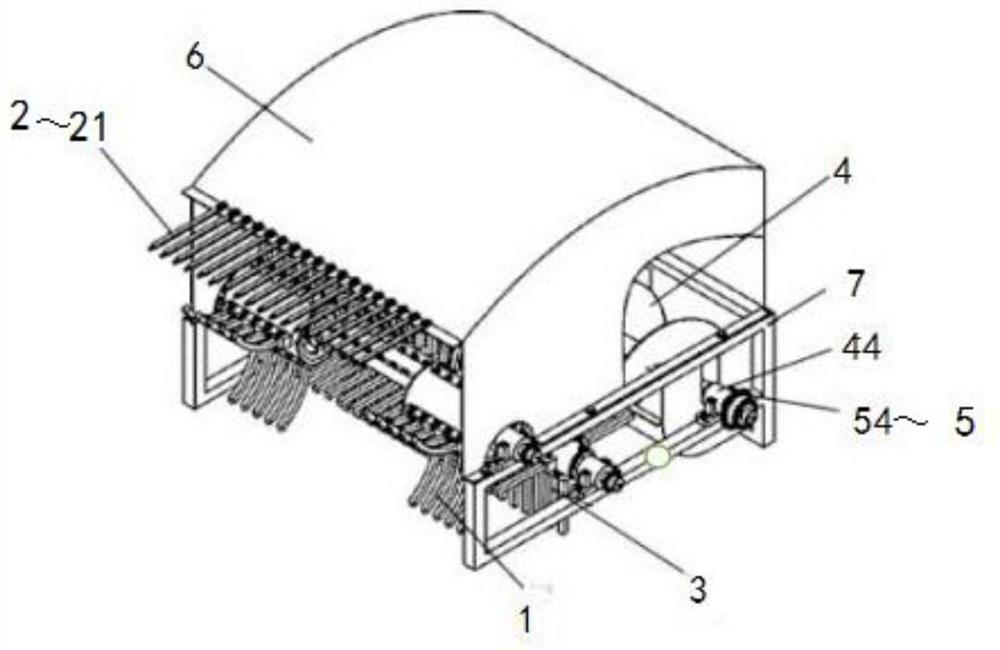

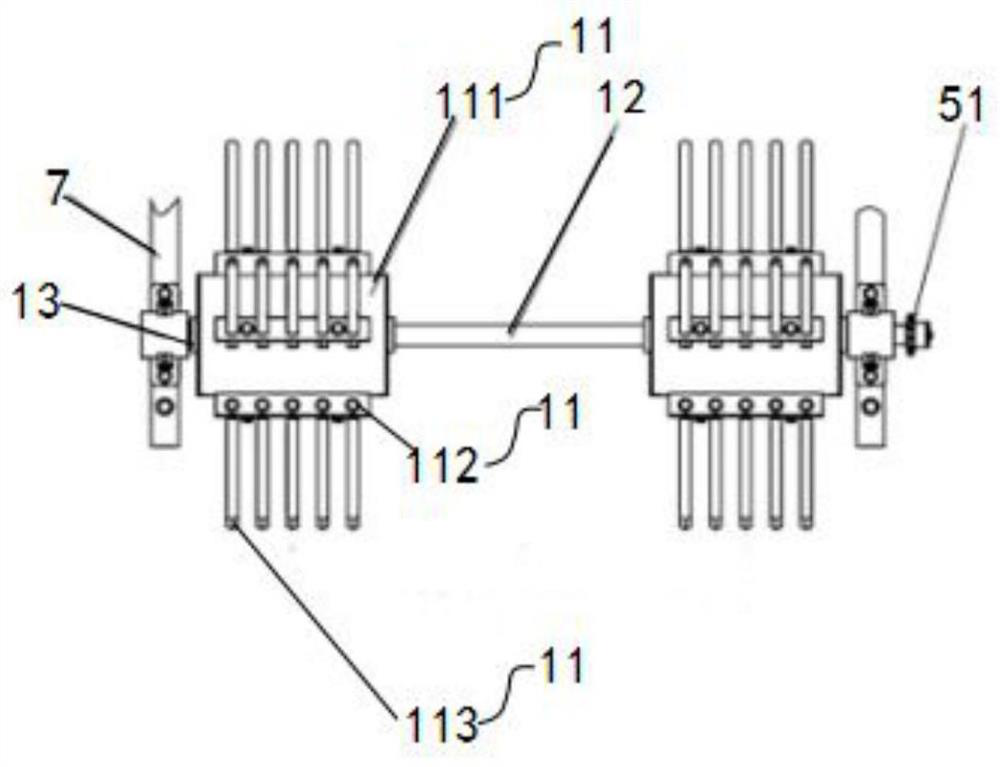

[0046] Please also refer to Figure 1 to Figure 8 Now, a specific embodiment of a corn combing and ear-picking head with adjustable spacing provided by the present invention will be described. This kind of corn combing and ear picking platform includes combing and ear picking mechanism 1, grain dividing component 2, anti-blocking mechanism 3, conveying auger 4, transmission device 5, shield 6 and frame 7, wherein the frame 7 is equipped with There is a protective cover 6, and the frame 7 is located at the bottom of the entire header; the combing and picking mechanism 1 is connected to the frame 7, and is provided with a plurality of combing and picking monomer mechanisms 11, and the adjacent combing and picking monomers The spacing between the mechanisms 11 is adjustable, and the single mechanism 11 for combing and picking ears is provided with a plurality of comb tooth assemblies at equal intervals in the upper direction, and the comb tooth assemblies include a plurality of c...

Embodiment 2

[0052] As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 8 The structure of the adjustable-spacing corn combing and ear-picking harvesting platform provided in this embodiment is basically the same as that of Embodiment 1, the difference being that the combing and ear-picking mechanism 1 also includes a first transmission shaft 12 and an adjusting and fixing device 13, wherein the first transmission shaft 12 is connected with the frame 7 and combing and picking the ear monomer mechanism 11; the adjustment fixture 13 is connected with the first transmission shaft 12 and the combing and picking the ear monomer mechanism 11 respectively, and the adjacent combs and picking The spacing between the ear monomer mechanisms 11 is adjusted by adjusting the fixing device 13 . Combing off the fringe picking unit mechanism 11 also includes a combing cylinder 111, which is connected with the first drive shaft 12, and a comb bar 113...

Embodiment 3

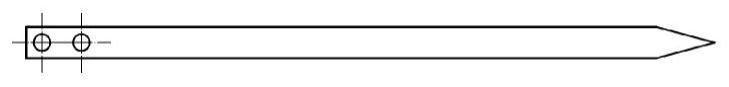

[0057] As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 8 , the structure of a kind of spacing-adjustable corn combing and ear-picking header provided in this embodiment is basically the same as that of Embodiment 2, the difference is that the grain dividing component 2 includes a plurality of grain dividing rods 21 arranged at equal intervals in the longitudinal direction, The front end of the splitting bar 21 is tapered, which can be better inserted between the plants for guidance. Compared with other shape structures, similar to plate shape and columnar structure, it is easier to guide the plants into the comb tooth bar 113.

[0058] The grain dividing assembly 2 is fixedly connected with the shield 6 through the slide rail, and the slide rail is provided with a movable mounting seat, the slide rail and the mounting seat are fastened by bolts, and the grain dividing assembly 2 is arranged on the mounting seat. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com