Vertical roll type corn harvester cutting table

A technology for corn harvesters and headers, which is applied to headers, harvesters, agricultural machinery and implements, etc., can solve problems such as hindering the development of vertical roller headers and poor row spacing adaptability of headers, and achieve improved row spacing adaptability, The effect of reducing power consumption and increasing the width of ear picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

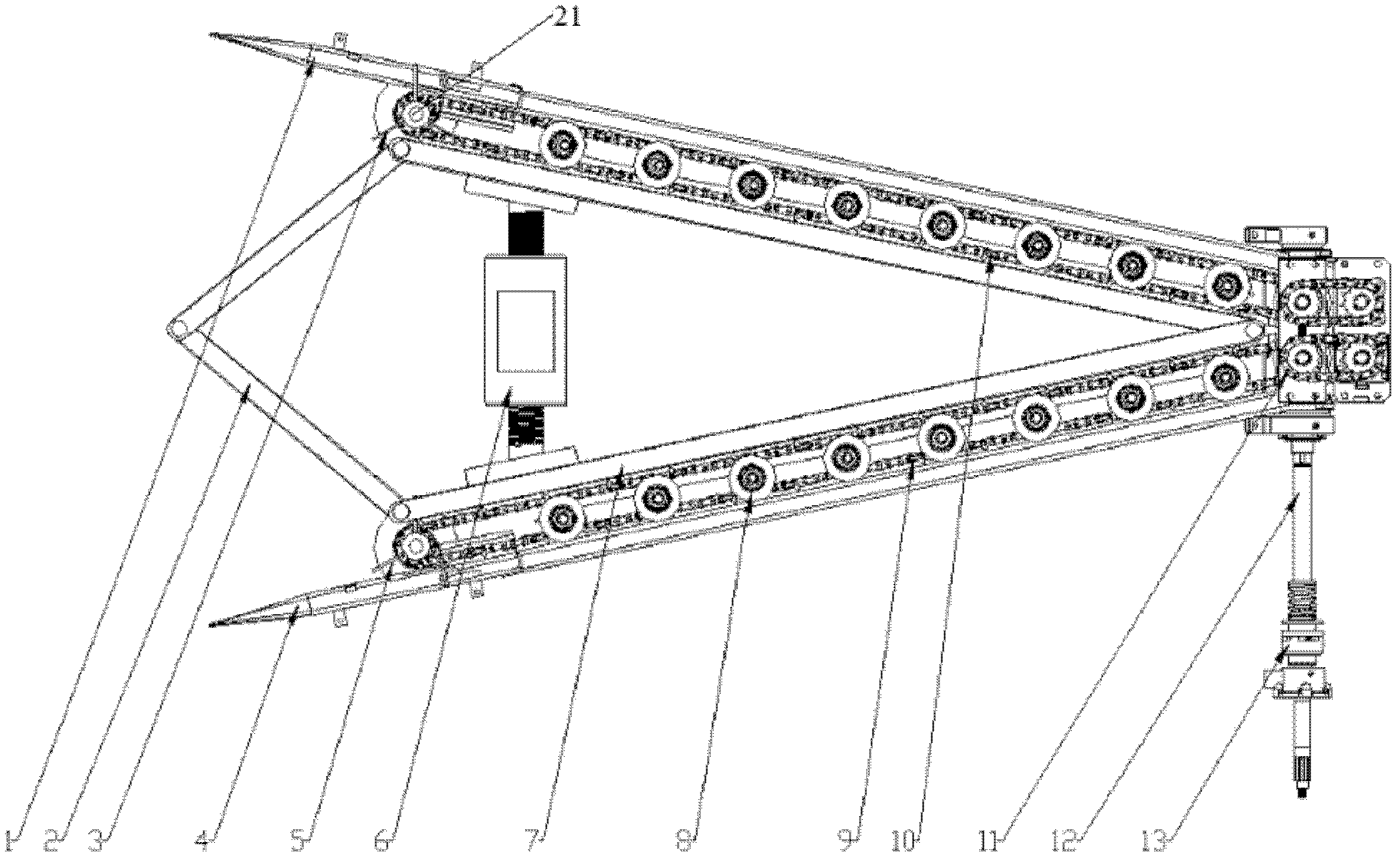

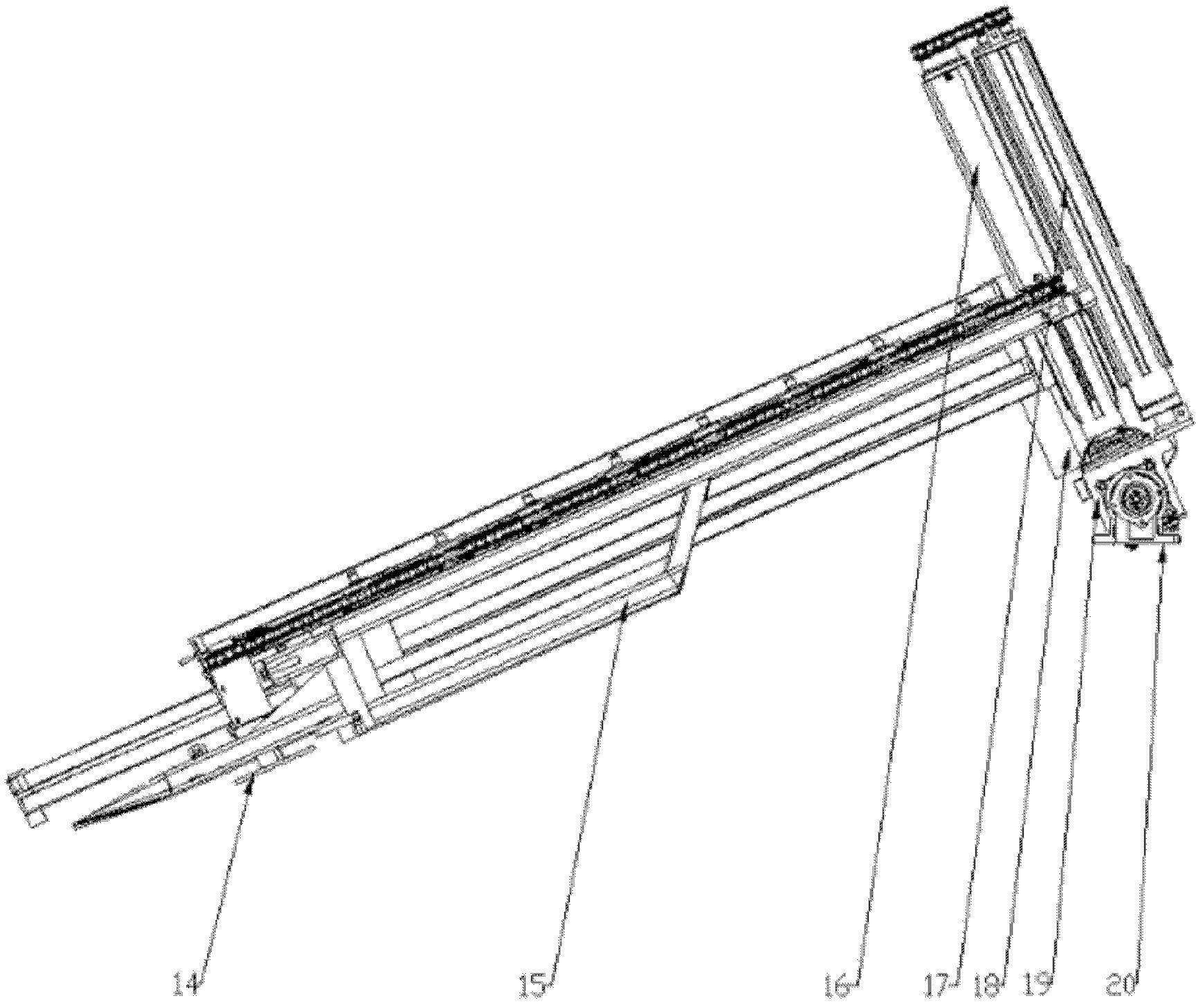

[0019] A vertical roller corn harvester header, such as figure 1 with figure 2 As shown, the ear picking roller 16 is installed coaxially with the driving sprocket 11 and is connected with the stem roller 17, the driven sprocket 21 is installed coaxially with the cutter 14, and the left clamping conveyor chain is equipped with on the driven sprocket 21 both sides 9 and the right clamping conveyor chain 10, the left clamping conveyor chain 9 and the right clamping conveyor chain 10 are tensioned and supported by the support wheel 8, the clutch assembly 13 is connected with the driving sprocket 11 and the ear picking roller 16 through the transmission shaft 12, and the row distance The adjusting lead screw 6 is fixed on the clamping guide rail 7, the lower part of the clamping guide rail 7 is provided with a support frame 15, the transmission box bracket 20 is connected to the transmission box 19, the transmission box 19 is connected to the grain-dividing clamping device bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com