Method for manufacturing hip-shaping female jeans with adjustable waistline size

A production method and technology for jeans, which can be applied to trousers, tools for sewing clothes, etc., can solve the problems of multi-process, single sewing method, and lack of beauty of female buttocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

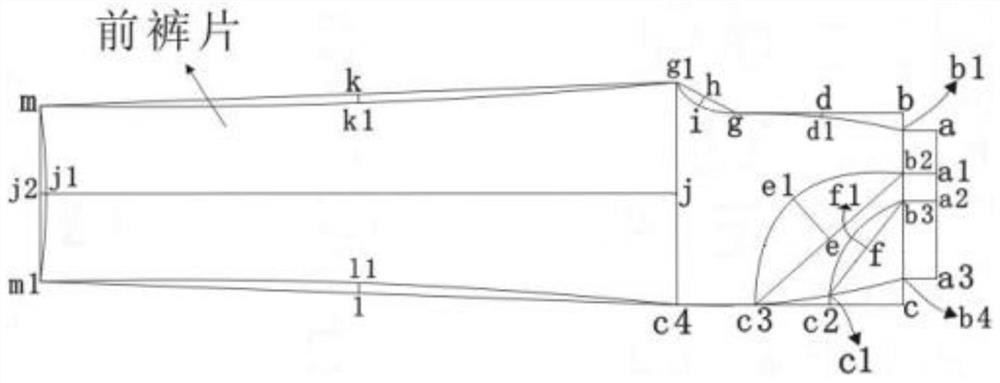

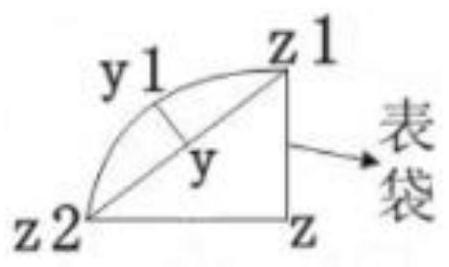

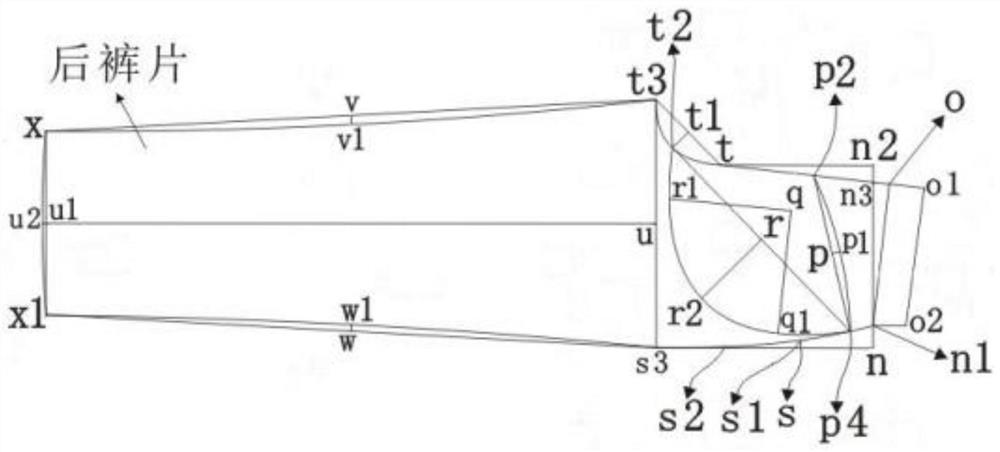

[0052] A method for manufacturing hip-plastic women's jeans with adjustable waist circumference, the method comprises the process of making front trousers pieces, making rear trousers pieces, and combining the front and rear trousers pieces. The production process of the front trousers piece includes: drawing of the front trousers piece, drawing of the front pad pocket cloth, drawing of the front inner pocket cloth, drawing of the front watch pocket, zipper sewing and pocket sewing. The production process of the rear trousers includes: drawing of the rear trousers, sewing of the plastic hip bag, sewing of the rear pocket and sewing of the Yuk dividing line. The combined sewing process of front and rear trousers includes: combined sewing of front and rear crotch, combined sewing of front and rear side seams, combined sewing of waistband, hook and loop sewing, and belt climbing sewing. The cutting of the front and rear trousers is based on the clean pattern of the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com