Integral shed cloth for through passage

A through-channel, integral technology, applied in the field of integral shed fabrics for through-channels, can solve the problems of increasing the chance of wearing shed fabrics, water seepage at the elbows of shed fabrics, and many overlapping parts for sewing, so as to improve the performance of the product , Simplify the sewing process and reduce the sewing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

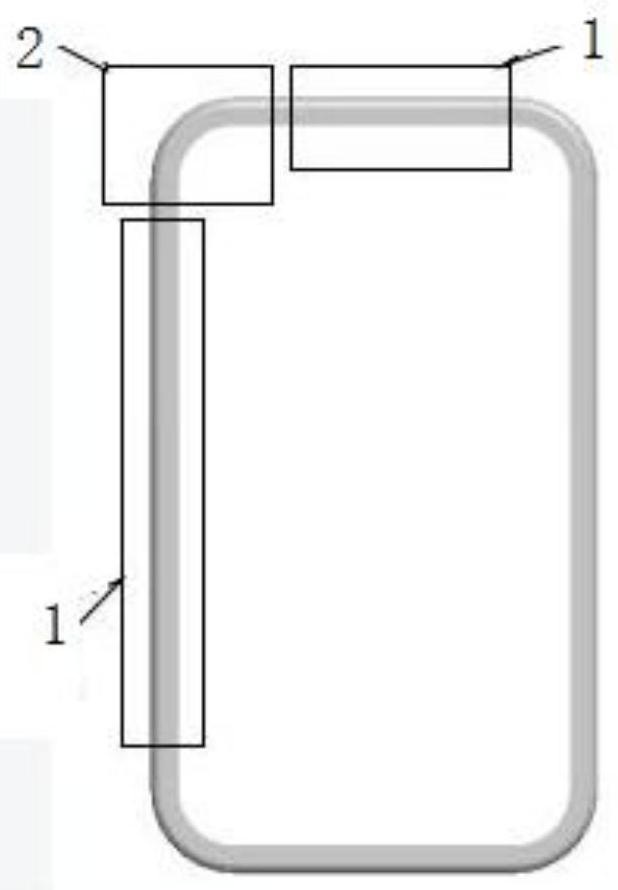

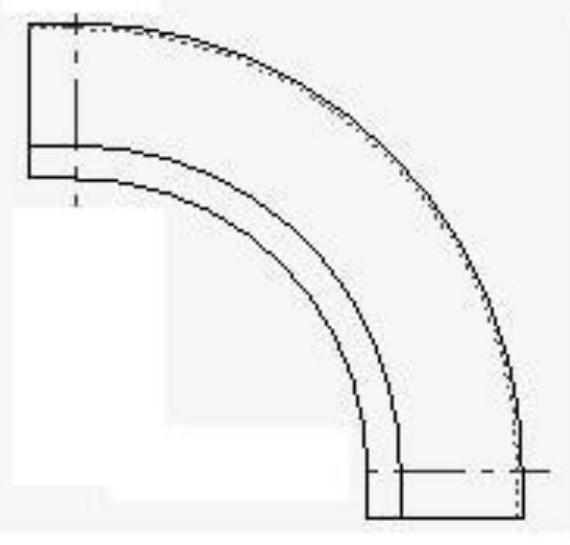

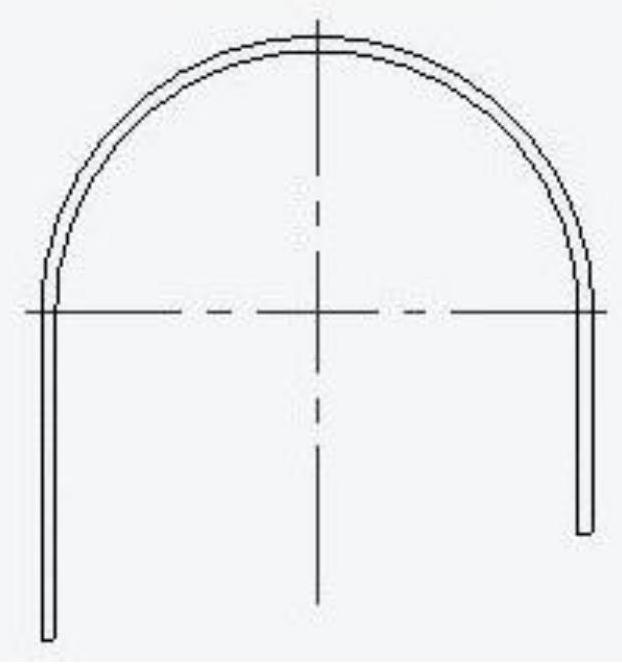

[0018] The integrated shed fabric for the passageway involved in this embodiment is an integral rectangular or trapezoidal ring structure formed by connecting four sections of straight fabric 1 and four elbows 2 at intervals; the straight fabric 1 is a linear structure with a U-shaped cross section. , the outer edge is linear; the elbow 2 is an arc-shaped structure with a U-shaped cross section, the outer edge is arc-shaped, and the inner end of the U-shape is longer than the outer end.

[0019] When using the integrated tent fabric for the passageway involved in this embodiment, according to the design requirements, a set number of tent cloths are connected with sewing threads through a sewing machine to form a tent cloth composition for the passageway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com