A kind of reinforcing fabric for airbag and its application

A technology of airbags and fabrics, applied in the direction of fabrics, vehicle safety arrangements, pedestrian/passenger safety arrangements, etc., can solve the problems that do not meet the development trend of cost reduction and affect the storage of airbags, so as to improve storage and simplify sewing Process and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

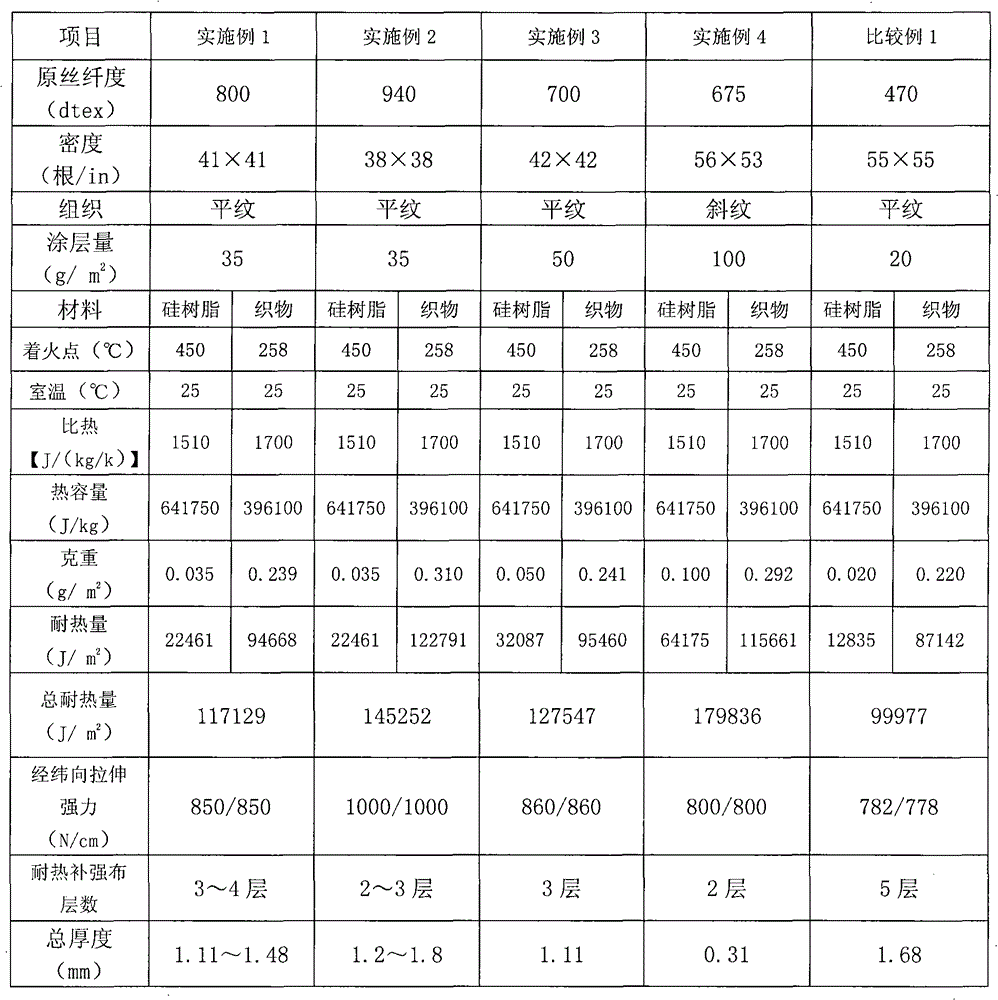

[0027] The warp and weft yarns are all nylon 66 filaments with a total fineness of 800dtex, a number of 210, and a circular cross section. Warp the above-mentioned filaments, and then weave them into plain weave fabrics with a water jet loom; use silicone resin and coat them with a doctor blade method to obtain a warp density of 41 strands / inch and a weft density of 41 strands / inch , the coating amount is 35g / m 2 The invention discloses a reinforcing fabric for an airbag, and the reinforcing fabric is used in preparing the airbag. The relevant physical properties of the fabric were evaluated and are shown in Table 1.

Embodiment 2

[0029] The warp and weft yarns are made of nylon 66 filaments with a total fineness of 940dtex, 140 threads, and a circular cross section. Warp the above-mentioned filaments, and then weave them into plain weave fabrics with a water jet loom; use silicone resin and coat them with a doctor blade method to obtain a warp density of 38 threads / inch and a weft density of 38 threads / inch , the coating amount is 35g / m 2 The invention discloses a reinforcing fabric for an airbag, and the reinforcing fabric is used in preparing the airbag. The relevant physical properties of the fabric were evaluated and are shown in Table 1.

Embodiment 3

[0031] The warp and weft yarns are made of nylon 66 filaments with a total fineness of 700dtex, 108 threads, and a circular cross section. Warp the above-mentioned filaments, and then weave them into twill fabrics with a water-jet loom; use silicone resin and coat them with a doctor blade method to obtain a warp density of 42 threads / inch and a weft density of 42 threads / inch , the coating amount is 50g / m 2 The invention discloses a reinforcing fabric for an airbag, and the reinforcing fabric is used in preparing the airbag. The physical properties of the fabric were evaluated and are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com