Sewn products and sewing methods of fabrics

A technology for sewing products and fabrics, which is applied in the directions of manual sewing seams, sewing equipment, cloth feeding mechanisms, etc., can solve problems such as no specific technical issues recorded, no disclosure, etc., to ensure the strength, simplify the sewing process, and eliminate the undulating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

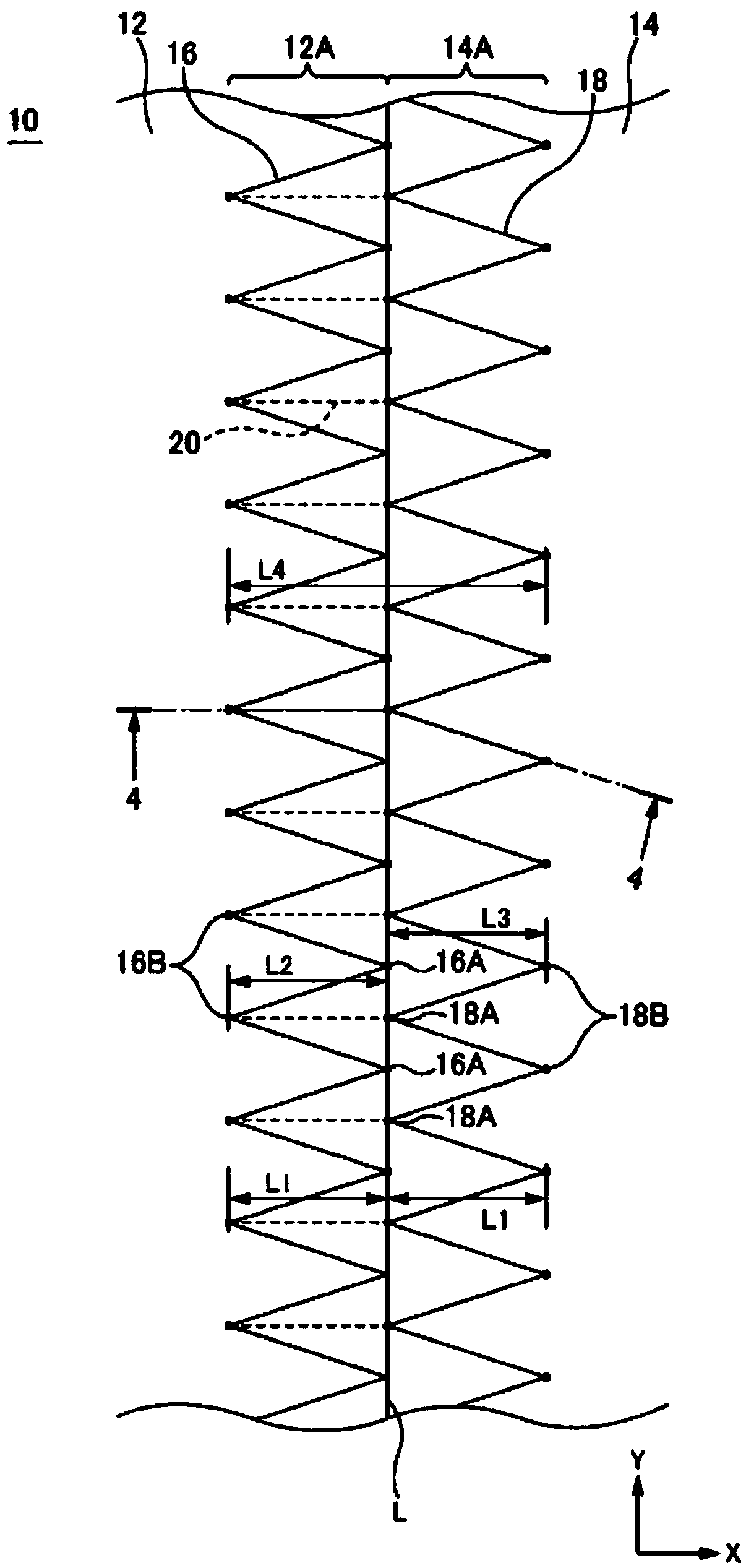

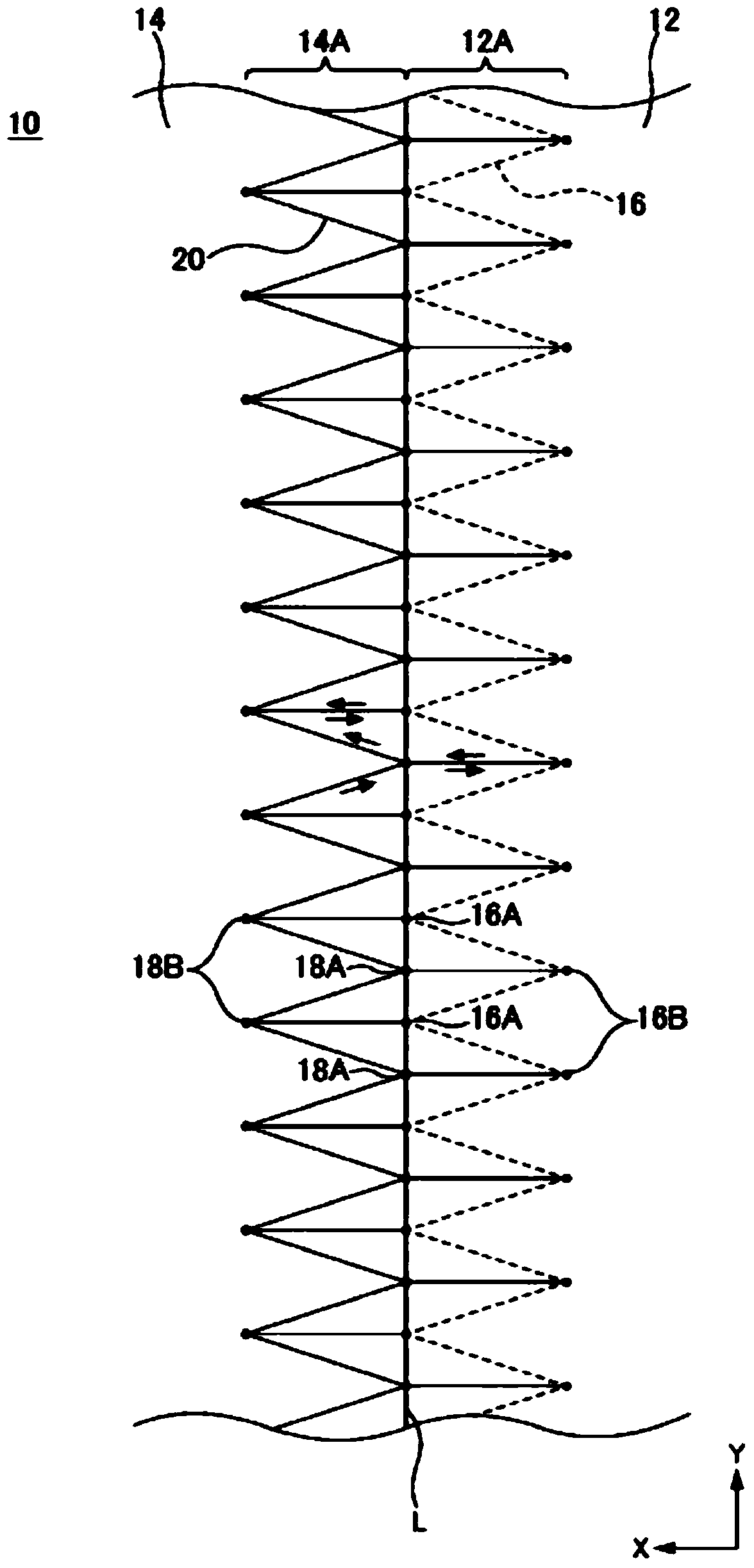

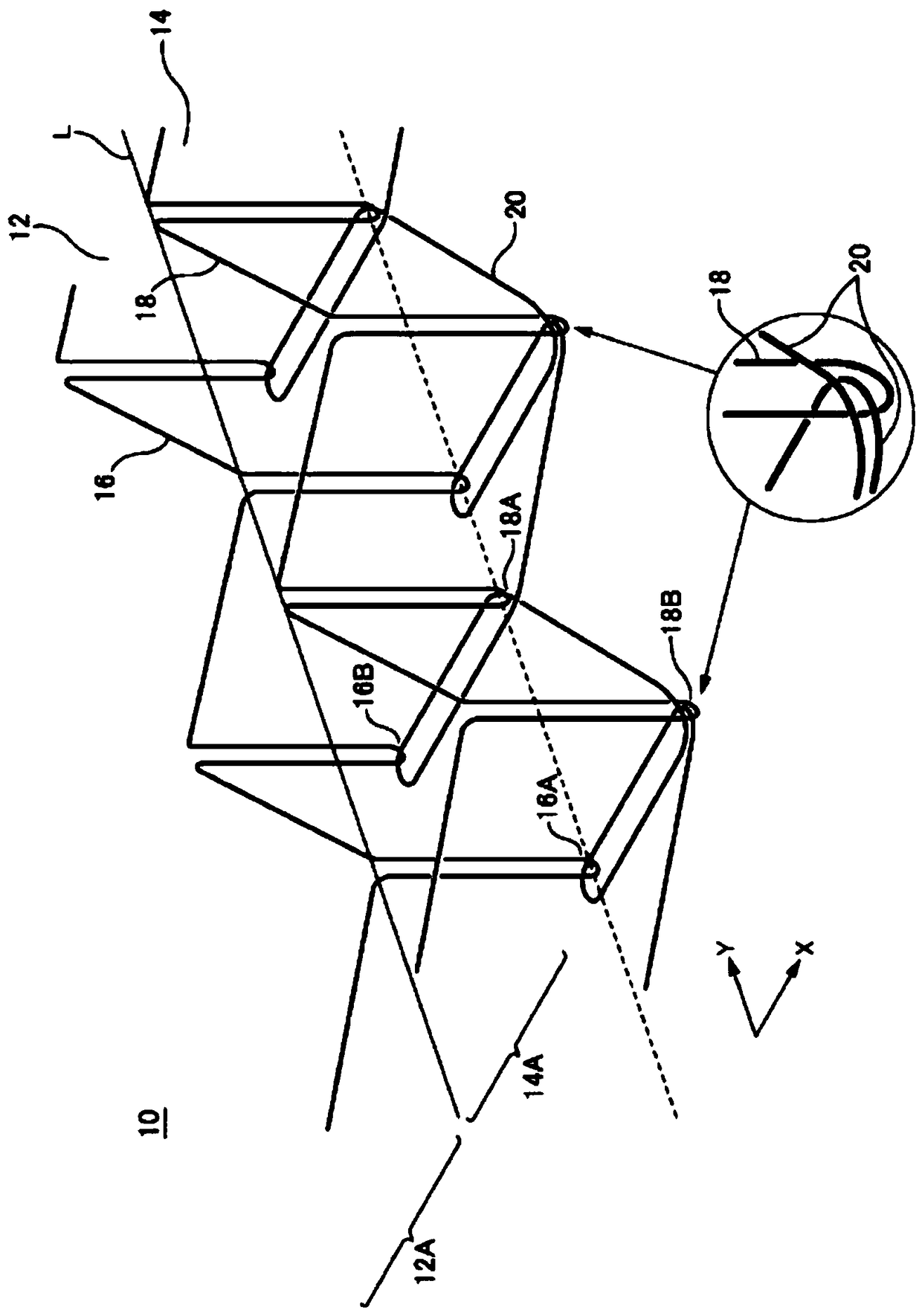

[0059] Refer to the attached Figure 1 One embodiment of the present invention will be described. figure 1 It is a plan view showing one surface of a sewn product 10 according to one embodiment, figure 2 It is a top view showing the other surface of the sewn product 10 . As shown in these figures, the sewn product 10 is made by using the end edge (hereinafter also referred to as "tape edge") 12A of the fastener tape 12 as an example of the first cloth, and the material thicker than the fastener tape 12 as the second cloth. It is a sewn product in which the edge (hereinafter also referred to as "cloth edge") 14A of the main fabric 14 of the fabric is sewn in a butt-butted state without overlapping. The zipper tape 12 is made of fabric or knitted fabric. The main fabric 14 is a fabric forming clothes, bags, etc., and is, for example, felt fabric, knit fabric, wool knit compressed fabric, jersey fabric, etc., but is not limited thereto. The sewn product 10 is clothes, bags,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com