Automobile glass lifting system

A lifting system, automotive glass technology, applied in construction, door/window fittings, wing fan control mechanism, etc., can solve problems affecting glass lifting, winding obstacles, steel rope corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

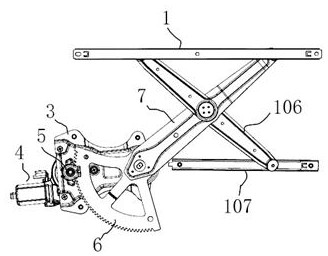

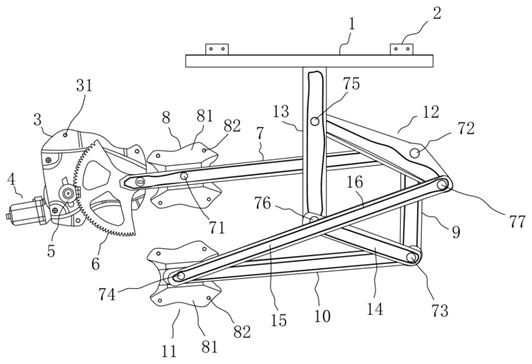

[0014] Such as image 3 The automobile glass lifting system of the present invention as shown includes a glass support arm 1, a motor seat plate 3, a motor 4, a gear 5, a sector tooth plate 6 and a sector tooth plate swing arm 7, the motor 4 is installed on the motor seat plate 3 and the gear 5 is installed On the output shaft of the motor 4, the first fastening installation holes 31 are distributed on the motor seat plate 3, the sector tooth plate 6 is meshed with the gear 5 for transmission, and one end of the sector tooth plate swing arm 7 is fixedly connected to the sector tooth plate 6, the sector tooth plate 6 One end of the tooth plate swing arm 7 close to the fan-shaped tooth plate 6 is hingedly mounted on the first hinged seat plate 8 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com