Copper alloy sheet material, manufacturing method thereof, and deep-drawn product

A manufacturing method and technology for copper alloys, which are applied to manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of deteriorating deep drawing workability without forming grains, harsh processing conditions, and inability to stabilize deep drawing workability, and achieve excellent deep drawing processing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~11

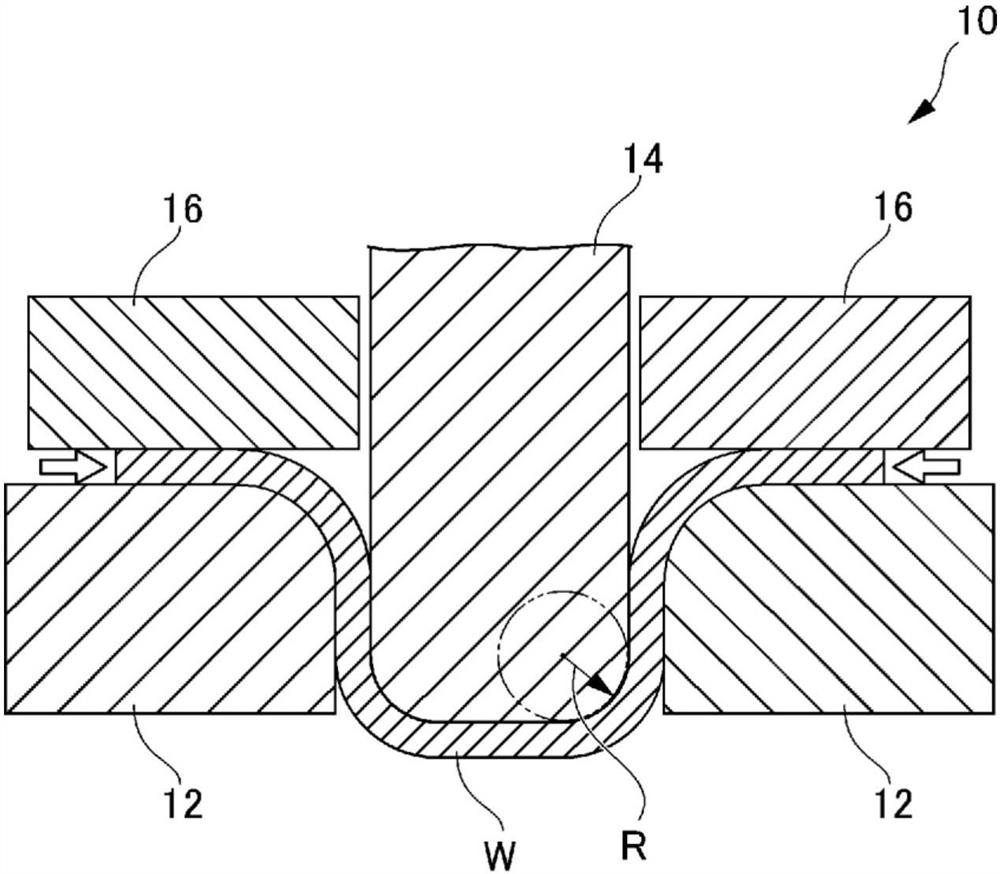

[0139]Copper alloy raw materials having the composition shown in Table 1 were melted in a high-frequency melting furnace under the atmosphere and cast to obtain an ingot having a thickness of 30 mm, a width of 100 mm, and a length of 150 mm. Next, in an inert gas atmosphere, a homogenization heat treatment of heating and holding at 1000° C. for 1 hour was performed, and hot rolling was immediately performed to obtain a hot-rolled sheet having a thickness of 10 mm, which was then immediately cooled. Next, surface cutting and cold rolling are sequentially performed so that the sheet thickness becomes 0.25 to 1.0 mm. Then, solution heat treatment was performed at 800°C to 990°C for 1 minute, and cooling was performed immediately thereafter, and intermediate heat treatment was performed at 300°C to 600°C for 1 hour. Next, cold finish rolling of 0.1% to 60% is carried out at the highest temperature TR of the material shown in Table 3, and then the elongation δ of the material shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com