Bubble porous body and method for producing the same

A technology of porous bodies and bubbles, applied in the field of porous porous bodies and their manufacture, can solve the problems of lack of heat resistance, deterioration, and release of low molecular siloxane components, and achieve the effect of not impairing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

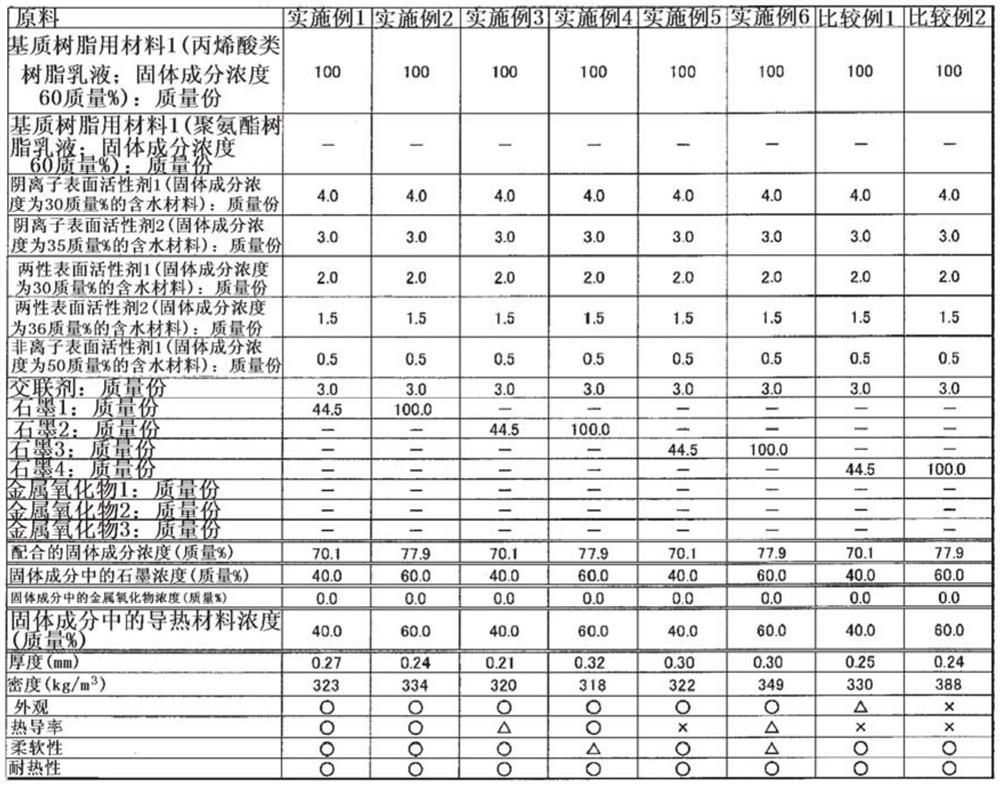

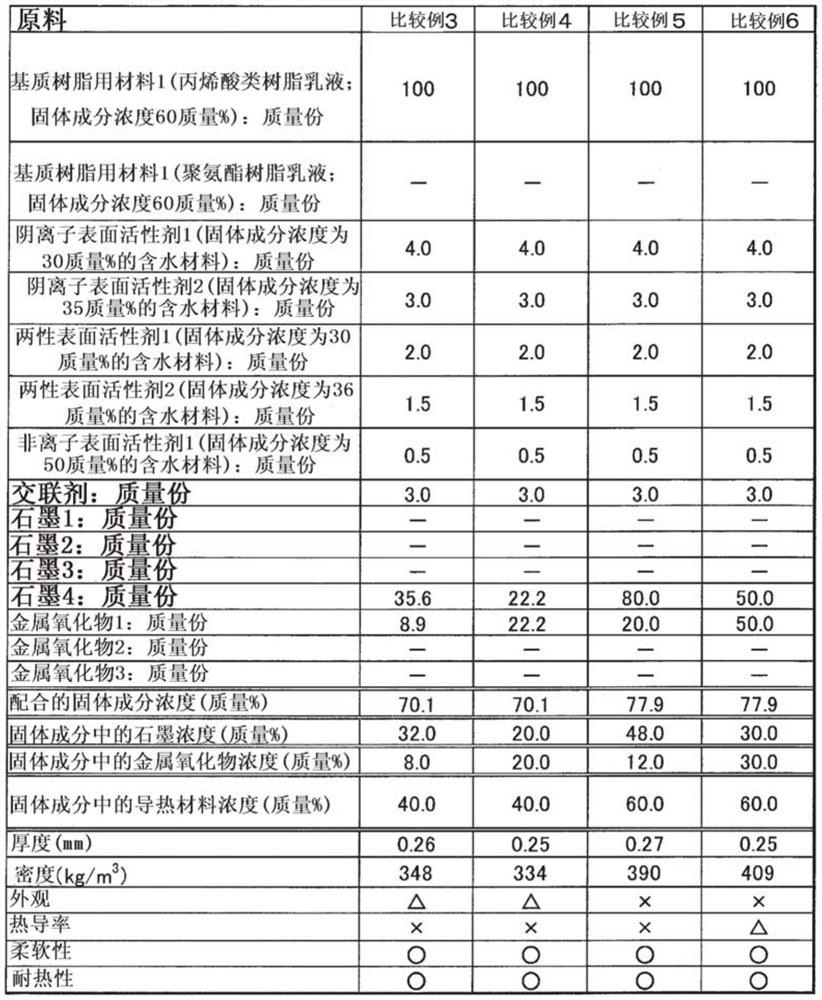

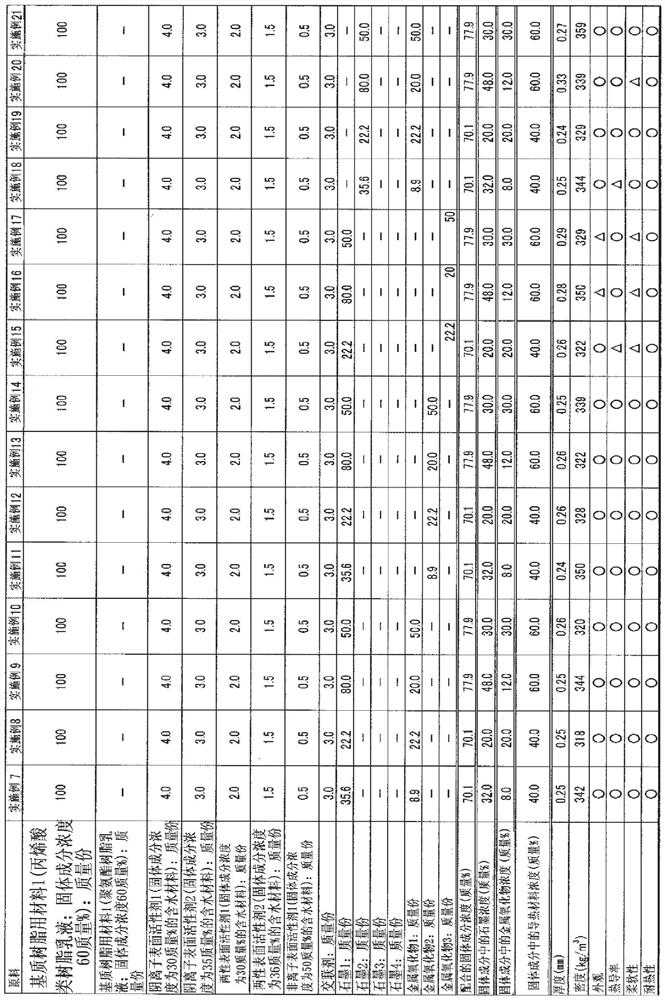

[0109] Graphite 1, Anionic Surfactant 1, Anionic Surfactant 2, Amphoteric Surfactant 1, Amphoteric Surfactant 2, and Nonionic Surfactant 1 were mixed in the proportions shown in the table below, and a cross-linking agent was added thereto, An aqueous dispersion of graphite 1 was prepared, added to 100 parts by mass of the above-mentioned material 1 for matrix resin, and mixed to prepare liquid compositions for Examples 1 and 2, respectively.

[0110] The total solid content concentration of the liquid composition, the solid content concentration of the thermally conductive material, and the like are as described in the following table. The pH of the liquid composition was 8.4. In addition, the viscosity is also the viscosity range in which mechanical foaming is possible.

[0111] Each liquid composition prepared above was foamed by a mechanical foaming method (stirring 500 revolutions, stirring time 3 minutes, temperature 23° C.), and then, the above liquid composition was pl...

Embodiment 3 and 4

[0113] The liquid compositions for Examples 3 and 4 having the compositions shown in the following tables were prepared in the same manner, except that the graphite 2 was used instead of the graphite 1 in the preparation of the above-mentioned liquid compositions. The pH of each liquid composition was 8.4 similarly to the liquid composition of Example 1.

[0114] Except having used the liquid compositions of Examples 3 and 4, respectively, the sheet-like cellular porous bodies of Examples 3 and 4 were produced in the same manner as described above, and evaluated in the same manner. The results are shown in the table below.

Embodiment 5 and 6

[0116] In the preparation of the above-mentioned liquid compositions, except that graphite 3 was used instead of graphite 1, each liquid composition for Examples 5 and 6 having the compositions shown in the following table was prepared in the same manner. The pH and viscosity of each liquid composition were not significantly different from those of the above-mentioned examples, nor were there significant differences regarding bubble formation by the mechanical foaming method.

[0117] Except having used the liquid compositions of Examples 5 and 6, respectively, the sheet-like cellular porous bodies of Examples 5 and 6 were produced in the same manner as above, and evaluated in the same manner. The results are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com