LED mounting substrate, led

A technology for mounting, LED chips, applied in sustainable manufacturing/processing, final product manufacturing, printed circuits, etc., can solve problems such as poor heat dissipation, insufficient heat dissipation function of solder pads, etc. damage, easy to locate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

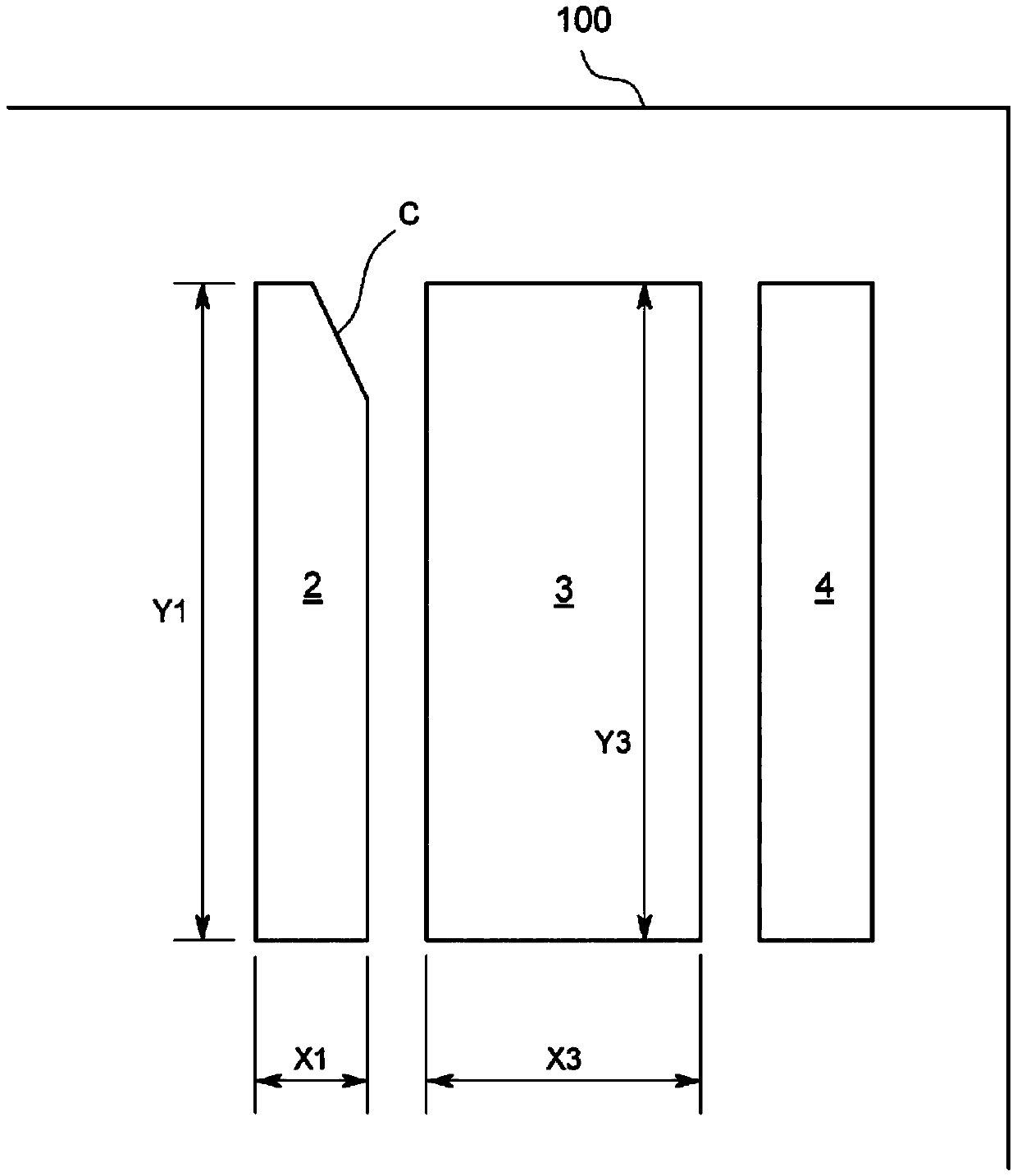

[0041] The LED mounting substrate 100 (hereinafter also referred to as "substrate 100") of the present embodiment is a printed circuit board having pads 2, 3, 4 formed on its surface for soldering. Terminals 13, 14, 15 of a surface mount type LED 1 (hereinafter also referred to as "LED 1").

[0042] Before describing this substrate 100, first, the outline of the LED 1 to be mounted on this substrate 100 will be described.

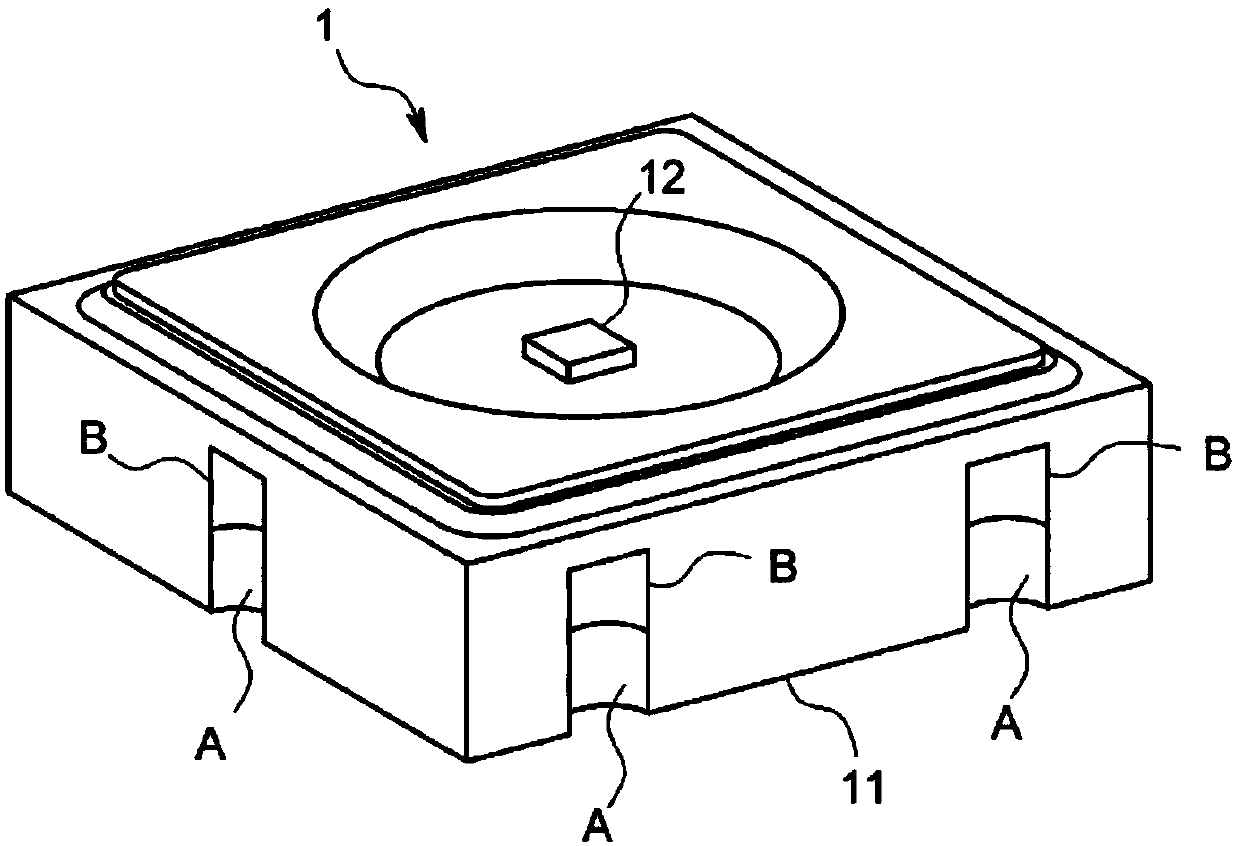

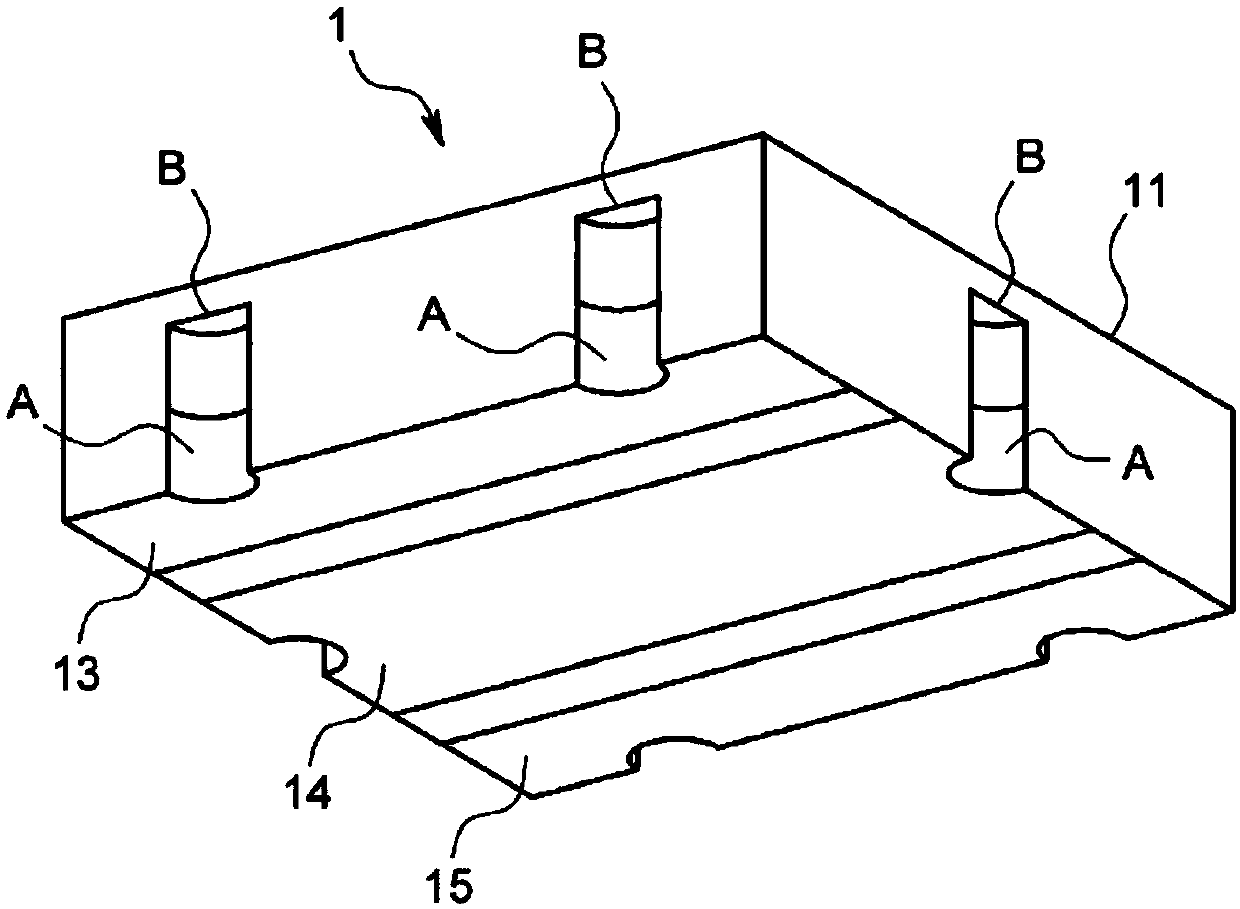

[0043] likefigure 1 , figure 2 As shown, the LED 1 is a surface-mounted LED in a flat rectangular shape (a square shape here), and includes a package body 11, an LED chip 12, and a plurality of (three here) terminals 13, 14, 15. The package body 11 is in the shape of a flat plate square, the LED chip 12 is bonded to the center of a bottomed circular hole opened on the surface side of the package body 11, and the plurality of terminals 13, 14, 15 are formed by gold plating. The back side of the package body 11 .

[0044] The terminals 13 , 14 , and 15 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com