Abnormal parts detection and flow adjustment sorting method

A kind of abnormal, sorter technology, applied in sorting, comprehensive factory control, manufacturing computing system, etc., can solve the problem of not effectively solving the relationship between parcel location, unable to ensure the correct delivery of subsequent parcels, and difficult to meet the needs of on-site sorting operations, etc. problems, to achieve the effect of improving the efficiency and accuracy of parcel sorting, realizing high-speed sorting and queue transportation, and improving the efficiency of sorting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

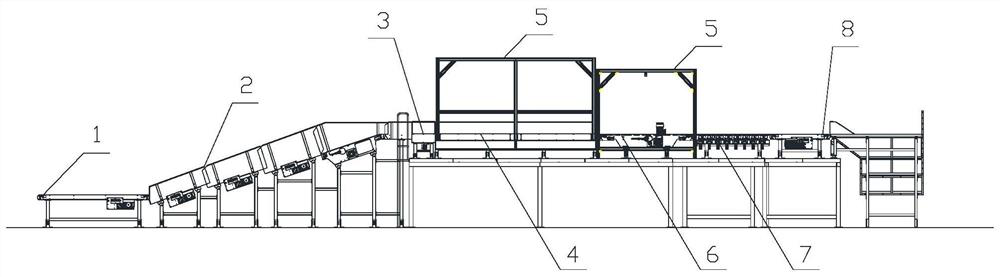

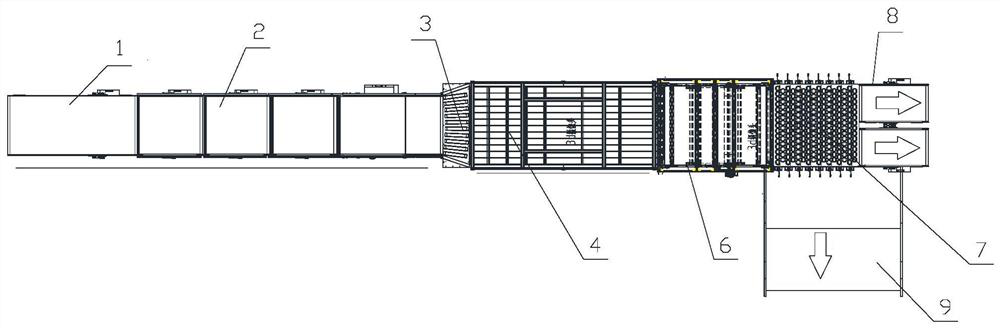

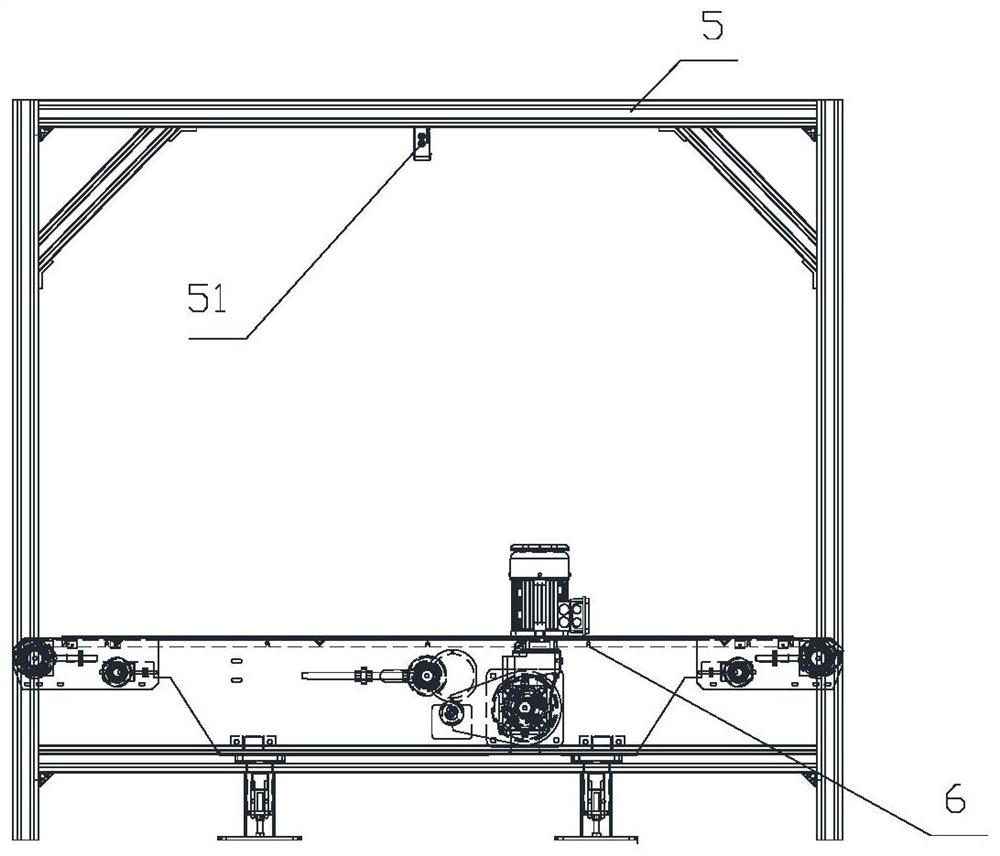

[0029] Example 1, as Figure 1 to Figure 4 As shown in the figure, the separation and diversion device including the abnormal parts detection and flow adjustment and sorting device described in the present application has an upper-line conveying device 1, a package separation device 2, a scattering separation device 3, and a single-piece separation device 4 connected in sequence along the conveying direction. , Visual identification device 5, identification conveyor belt 6, balance wheel sorter 7, shunt belt conveyor 8 and return belt conveyor 9.

[0030] Wherein, the package separation device 2 has several belt conveyors connected in sequence along the slope, and a vertical height drop is formed between adjacent belt conveyors, and each belt conveyor is driven by a separate servo motor.

[0031] The scattering separation device 3 includes several belt conveyors arranged in a divergent state along the conveying direction, and each belt conveyor is driven by a separate servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com