Parcel splitting, re-packaging and conveying method

A technology for conveying direction and parcels, which is applied in the direction of conveyors, conveyor objects, packaging, etc., which can solve the problems of unfavorable reconstruction of package conveying system miniaturization design, affecting the efficiency of sorting process execution, and large workload of on-site operations, etc., to achieve Guarantee high-speed operation and sorting efficiency, realize high-speed separation and single-queue transportation, and reduce work intensity and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

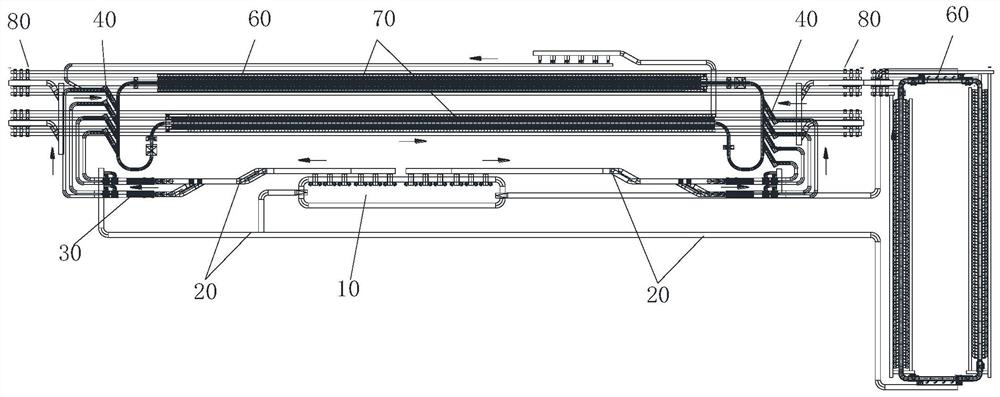

[0086] Example 1, such as figure 1 As shown, the parcel splitting and rebuilding conveying system using the conveying method described in this application is used to re-execute the conveying and sorting operations of automatic feeding and packing after splitting large parcels. The integrated scheme of splitting and building packages adopted can realize automatic and accurate conveying and sorting control, so as to correspondingly reduce the manual labor load and intensity of each operation area, shorten manual intervention and operation links, and improve the level of automated operation and distribution as a whole. Picking efficiency.

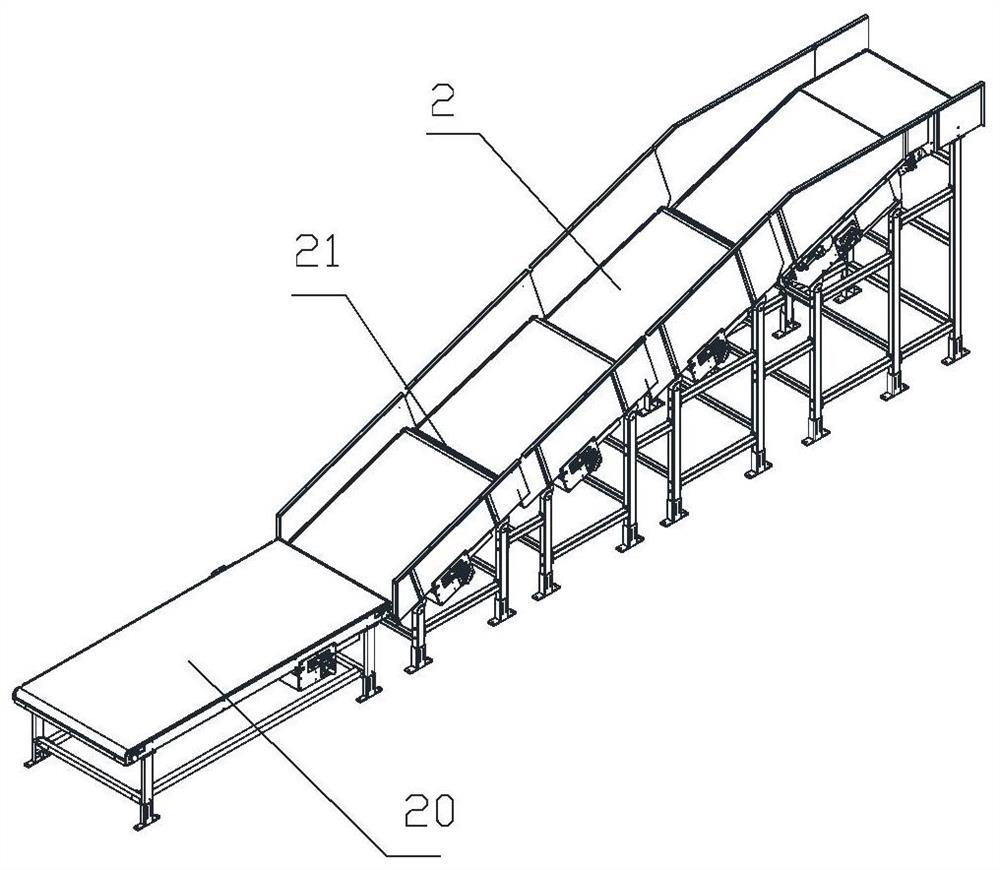

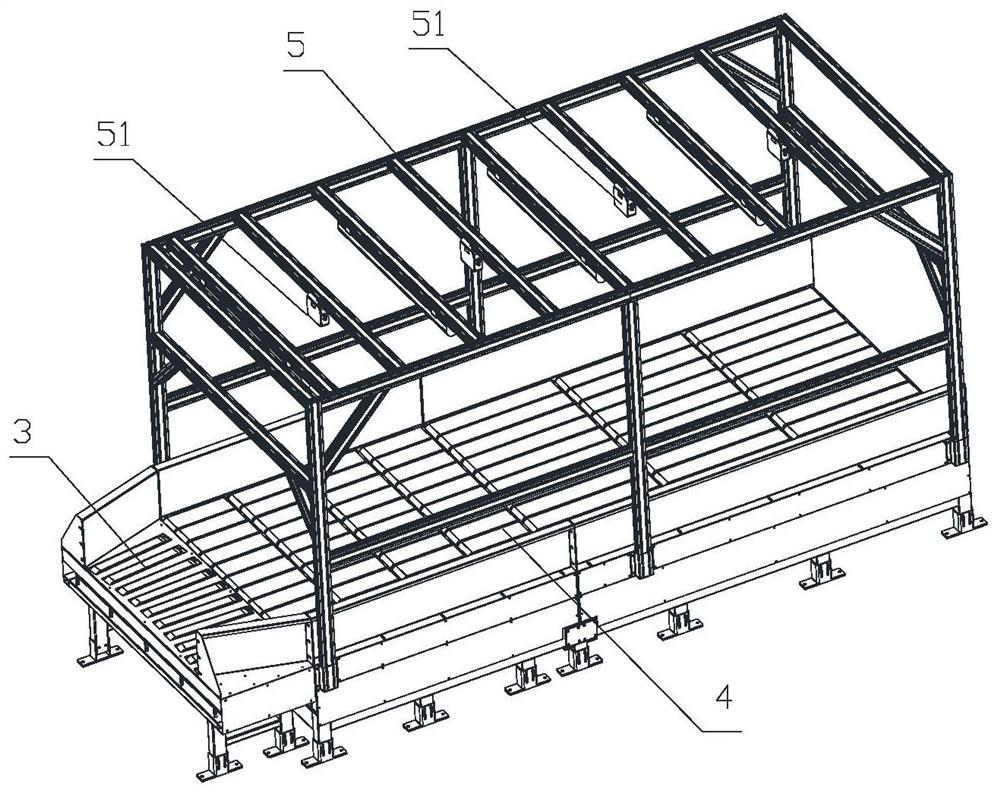

[0087] The parcel splitting and rebuilding conveying system is respectively connected with a dismantling and unpacking area 10, a supplying conveying line 20, a single-piece separation assembly 30, an introduction device 40, a cross-belt sorting device 60, and a compartment along the conveying direction. Porting device 70 and automatic packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com