Package splitting and rebuilding package delivery method

A technology for conveying direction and parcels, which is applied in the direction of conveyors, conveyor objects, packaging, etc., can solve the problems of unfavorable miniaturization design of the re-construction package conveying system, affecting the efficiency of sorting process execution, and large on-site workload, etc., to achieve Guarantee high-speed operation and sorting efficiency, realize high-speed separation and single-queue transportation, and reduce work intensity and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

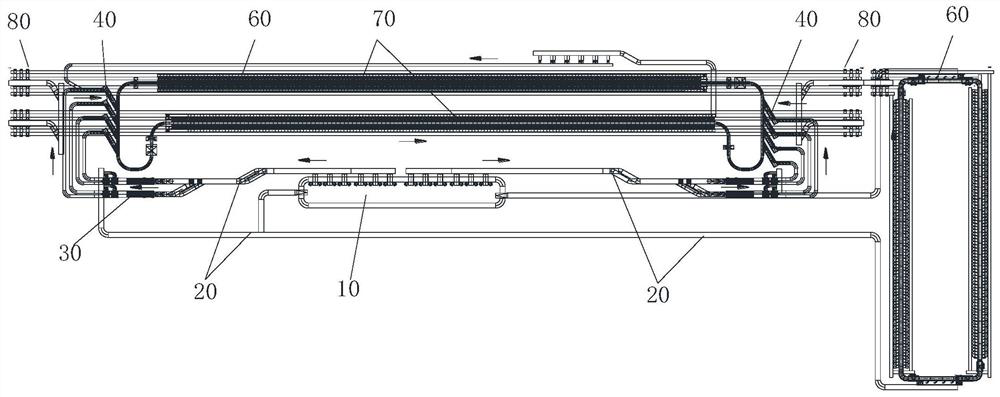

[0091] The grid opening device 70 is dispersedly arranged on the sorting loop line of the cross-belt sorting device 60, such as a grid opening sliding

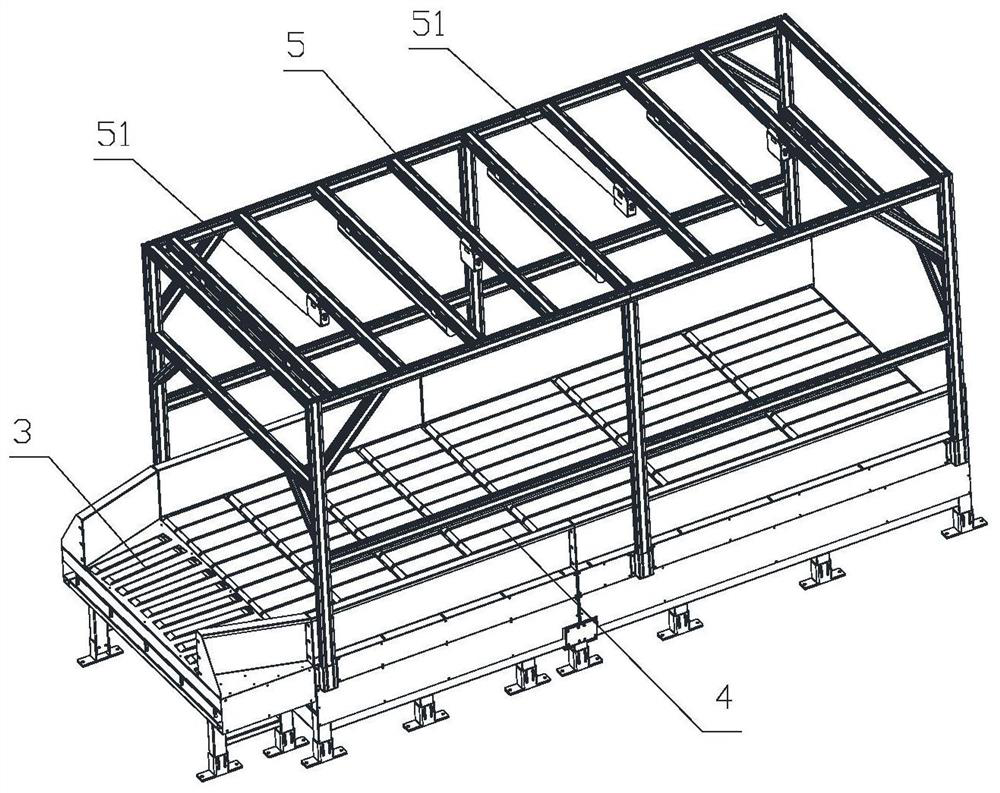

[0100] As shown in FIG. 7 to FIG. 12 , the introduction device 40 is arranged in front of the sorting loop line 201 of the cross-belt sorting device 60

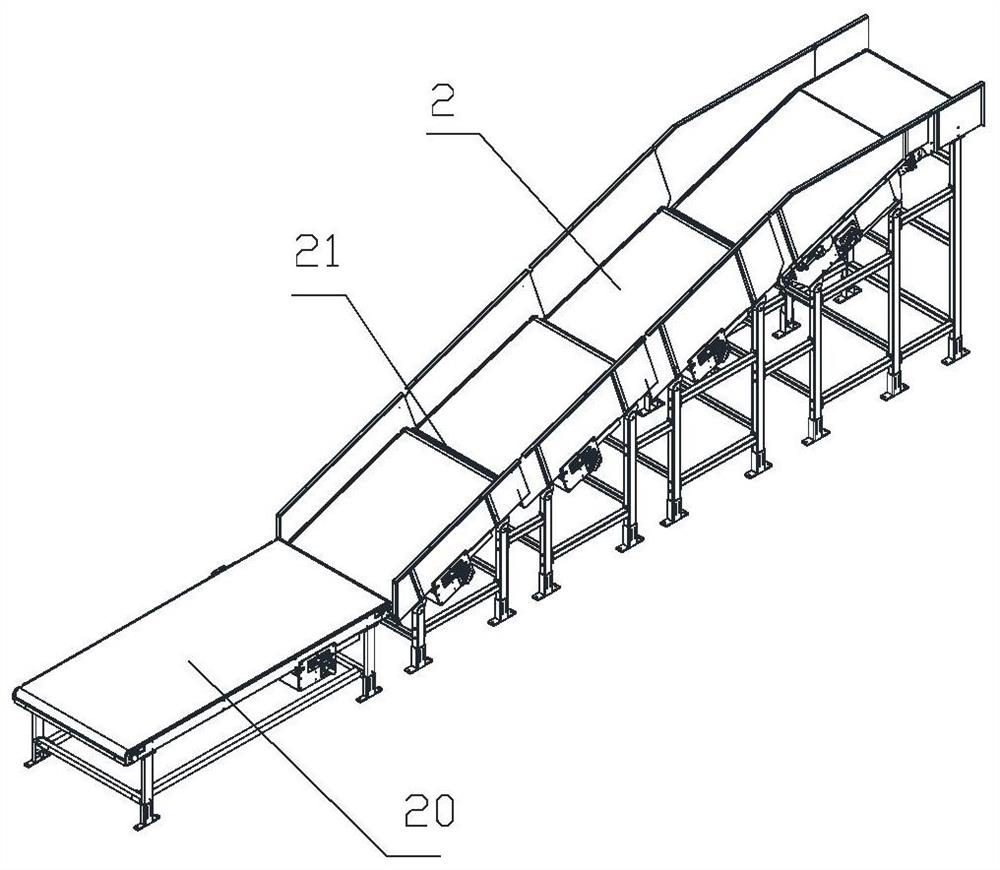

[0101] When the package to be sorted reaches the induction device area described in this application, first, the entry is composed of 3 belt conveyors

[0103] In the three-stage belt conveyor assembly, including the first unit single-drum fixed block 331, the front-end driven drum 332, the front-end

[0104] The first unit single-cylinder fixed block 331 and the first unit single-cylinder fixed block symmetrical piece 337 are a single adjustment groove;

[0105] The front driven roller 332 is respectively fixed in the first groove 3301, the third groove 3303 and the fifth groove 3305, and the front end drives the roller

[0106] Both ends of the front driven drum 332 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com