Universal crawler belt with reinforcing structure and for logistics transportation

A technology to strengthen the structure and logistics, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of not having internal shaft lubrication, not having lateral unloading assistance, not having pressure dispersion buffer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

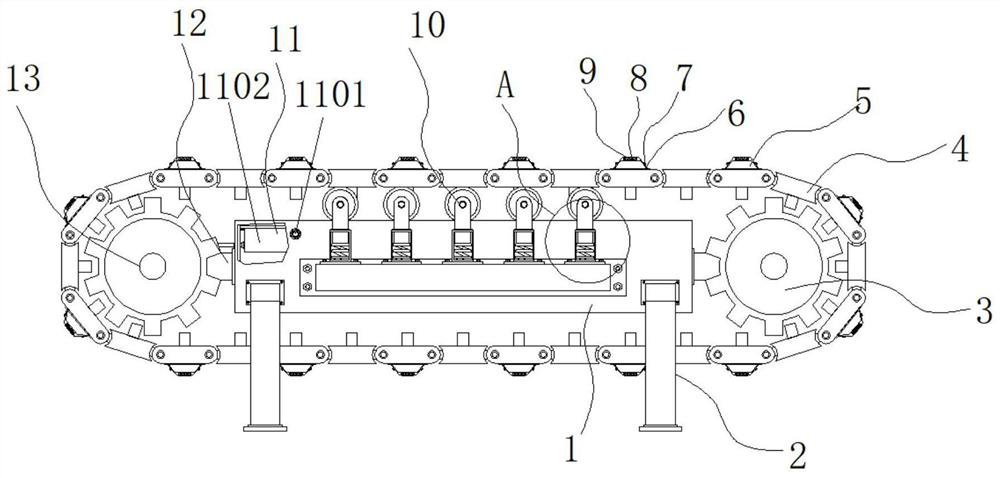

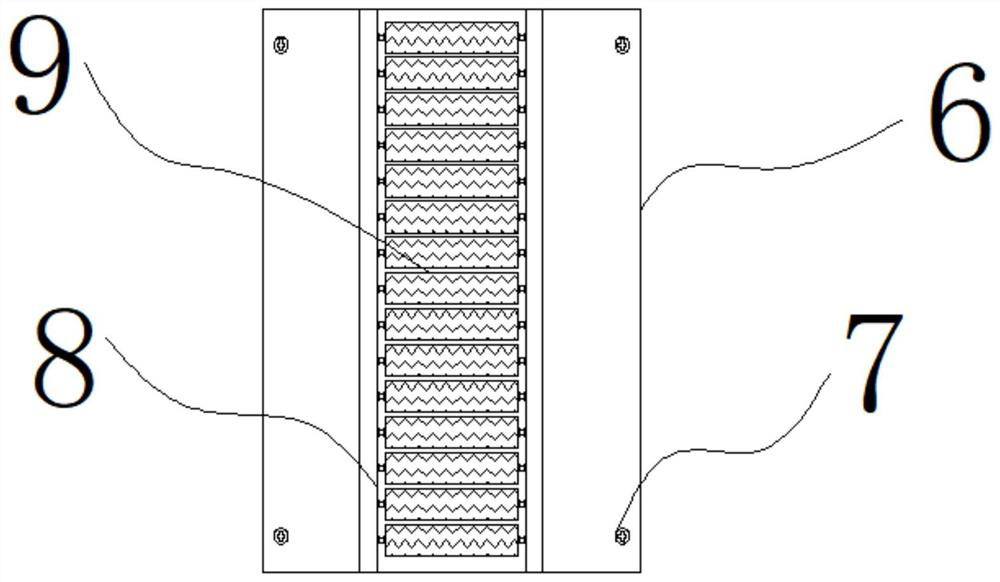

[0028] Example 1: See Figure 1-5 , a universal crawler belt with a reinforced structure for logistics transportation, including a main beam 1, supporting feet 2 are fixedly connected to both sides of the front end of the main beam 1, and fixed bushings 12 are respectively fixedly connected to both sides of the main beam 1, One side of the main girder 1 is movably connected with the supporting pulley 3 through the fixed bushing 12, and the other side of the main girder 1 is movably connected with the driving pulley 13 through the fixed bushing 12, and the outside of the main girder 1 is provided with a belt body 4. The top and both sides of the body 4 are respectively fixedly connected with multiple groups of ribs 5, and the top of the ribs 5 is provided with a material dragging auxiliary structure;

[0029] see Figure 1-5 , a universal crawler with a reinforced structure for logistics transportation also includes a material dragging auxiliary structure, the material draggin...

Embodiment 2

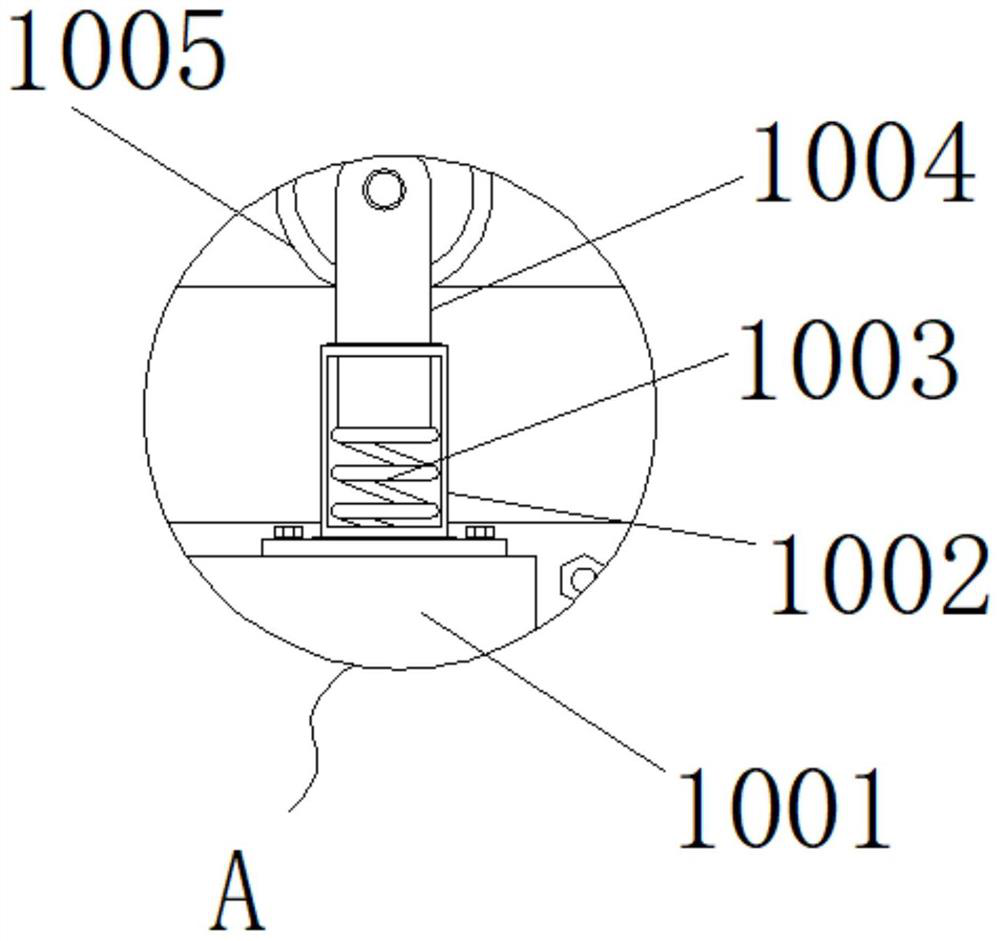

[0033] Embodiment 2: The front end of the main beam 1 is provided with a load-bearing buffer structure 10. The load-bearing buffer structure 10 is composed of a support plate 1001, a buffer sleeve 1002, a hard spring 1003, a wheel support 1004 and a load wheel 1005. The support plate 1001 is fixedly connected to the The front end of the main girder 1 and the top end of the support plate 1001 are fixedly connected with a buffer sleeve 1002, and the inside of the buffer sleeve 1002 is provided with a wheel support 1004, and the bottom end of the wheel support 1004 is fixedly connected with the bottom end of the buffer sleeve 1002. There is a hard spring 1003, and the internal movable connection at the top of the wheel support 1004 has a road wheel 1005;

[0034] The buffer sleeves 1002 are arranged at equal intervals;

[0035] The top of the road wheel 1005 is consistent with the horizontal plane at the bottom of the belt body 4;

[0036] Specifically, such as figure 1 with ...

Embodiment 3

[0037] Embodiment 3: A shaft lubricating structure 11 is provided at the top inside the main beam 1. The shaft lubricating structure 11 is composed of a sealing cover 1101, an oil storage box 1102, a conduit 1103 and a lubricating ring 1104. The sealing cover 1101 is fixedly connected to the main beam 1 On the top side of the front end, the oil storage box 1102 is fixedly connected to the top side of the main beam 1, one side of the oil storage box 1102 is fixedly connected to a conduit 1103, and the lubricating ring 1104 is fixedly connected to the inside of one side of the fixed bushing 12;

[0038]The conduit 1103 runs through one side of the main beam 1 and the top end of the fixed shaft sleeve 12 side and communicates with the inside of the lubricating ring 1104, and the top inside the lubricating ring 1104 is evenly provided with small holes;

[0039] Specifically, such as figure 1 and Figure 4 As shown, when the internal shaft needs to be lubricated, the sealing cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com