Material mechanical property universal testing machine with safety protection function

A universal testing machine and a technology of material mechanics, applied in the field of universal testing machines for mechanical properties of materials, can solve the problems of lack of cleaning structure, lack of automatic lubrication structure, lack of protective structure, etc., and achieve the effect of preventing personnel injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

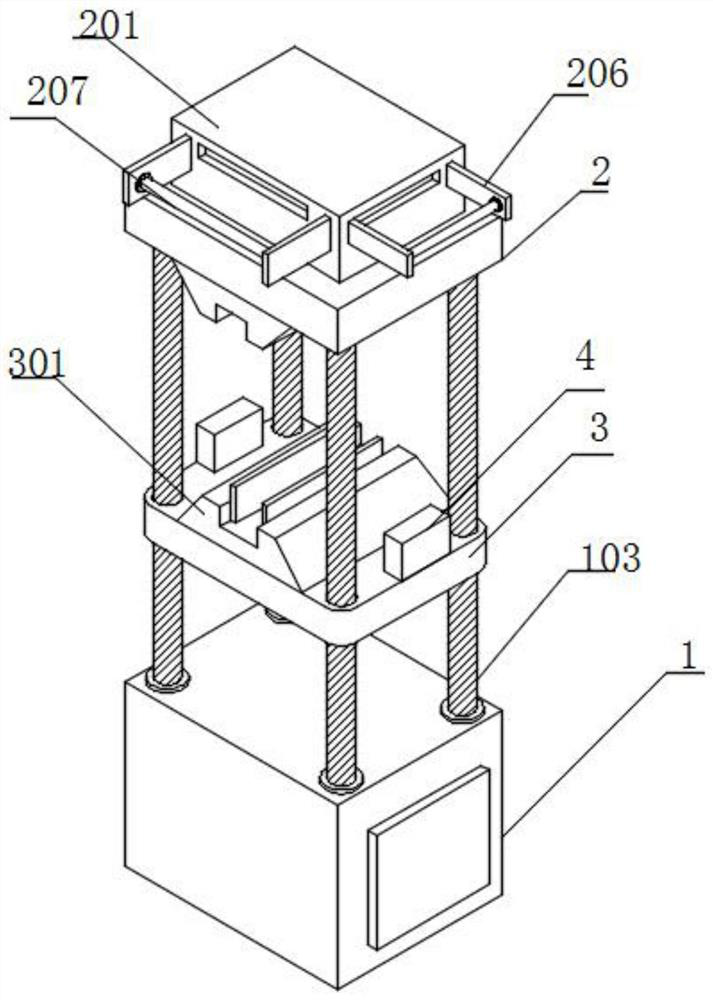

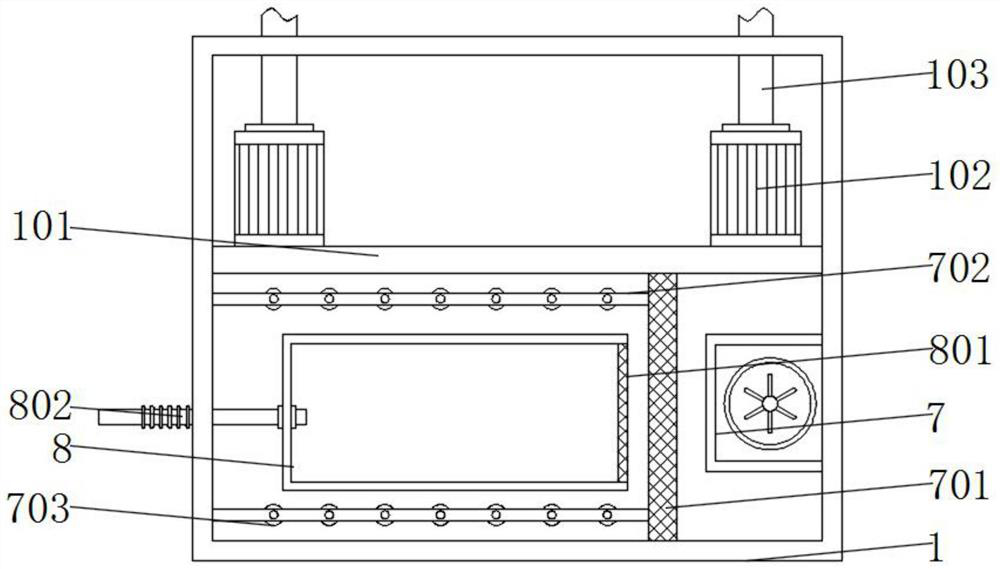

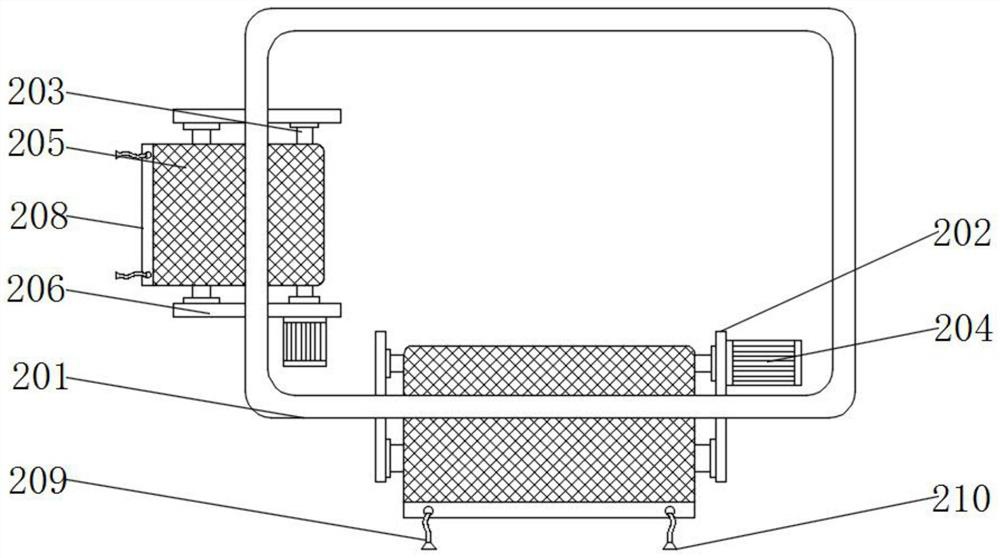

[0034] Example 2: See figure 1 and image 3 , an embodiment provided by the present invention: a universal testing machine for mechanical properties of materials with a safety protection function, a protective box 201 is installed on the top of the top plate 2, and multiple sets of fixing frames 202 are installed on the inner wall of the protective box 201 , the inner wall of the fixed frame 202 is equipped with a shaft 203, the outer wall of the fixed frame 202 is equipped with a first motor 204, and the output end of the first motor 204 is connected to one end of the first shaft 203, the first shaft A protective net 205 is installed around the outer wall of 203, an auxiliary frame 206 is installed on the outer wall of the protective box 201, a second shaft 207 is installed on the inner wall of the auxiliary frame 206, and a mounting strip 208 is installed at one end of the protective net 205, The inner wall of the installation bar 208 is equipped with a connecting line 209,...

Embodiment 3

[0035] Example 3: See Figure 4 , an embodiment provided by the present invention: a universal testing machine for mechanical properties of materials with a safety protection function, a clamper 301 is installed on the top of the auxiliary plate 3, and a clamping groove 302 is provided on the top of the clamper 301, and the clamping The inner wall of the holding groove 302 is equipped with a fixed shaft 303, and the outer wall of the fixed shaft 303 is equipped with a clamping plate 304. When the object is clamped, the object is placed inside the clamping groove 302, the electric telescopic rod 305 is activated, the electric telescopic rod 305 shrinks and drives the bottom of the clamping plate 304 to rotate, and the bottom of the clamping plate 304 rotates due to the fixed shaft The function of 303 can make the tops of the clamping plates 304 close to each other, so as to realize the clamping function.

Embodiment 4

[0036] Example 4: See Figure 5 , Figure 6 and Figure 7 , an embodiment provided by the present invention: a universal testing machine for mechanical properties of materials with a safety protection function, a partition plate 401 is installed on the inner wall of the lubrication box 4, a detector 402 is installed on the top of the partition plate 401, and the detector The outer wall of 402 is equipped with a detection film 403, the outer wall of the detection film 403 is equipped with a moving rod 406, one end of the moving rod 406 is equipped with a conductive block 407, the inner top wall of the detector 402 is equipped with a trigger plate 404, and the outer wall of the trigger plate 404 Two sets of conductive holes 405 are installed, the outer wall of the lubricating pipe 5 is installed with a control valve 501, the inner wall of the control valve 501 is installed with a fixed plate 502, the top of the fixed plate 502 is provided with a through hole 503, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com