Optical detection device and optical detection method for side wall of inner cavity of mobile phone camera bracket

A mobile phone camera and optical detection technology, which is applied in the field of optical detection, can solve problems such as the inability to obtain clear pictures of the side walls of the inner cavity, the inability to take complete pictures of the side walls of the inner cavity, and the impact on detection accuracy. Avoid Poor Image Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

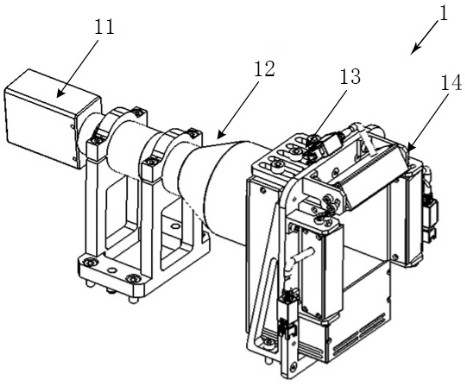

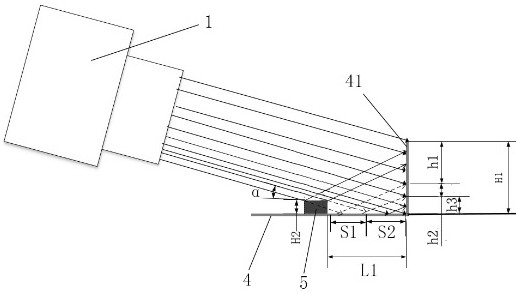

[0055] See Figure 1 to Figure 3 , the optical detection device of the mobile phone camera bracket inner cavity side wall in the present invention comprises the platform to be checked for placing the mobile phone camera bracket 4, and the mobile phone camera bracket on the platform to be checked that is electrically connected with the control unit 2 and controlled by the control unit 2 The optical assembly 1 that is photographed by the inner cavity side wall 41 of 4; the optical assembly 1 is installed on the support; the optical assembly includes an area array camera 11, a telecentric lens 12, a coaxial light source 13 and a strip light assembly 14; One end of the center lens 12 is fixedly installed on the area array camera 11, and the other end of the telecentric lens 12 is connected with the coaxial light source 13; The platform to be checked is provided with a bearing plane for positioning and placing the mobile phone camera support 4; the bearing plane It is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com