Injection allocation device

A technology of injector and faucet, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of poor deployment accuracy, inability to operate at the same time, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

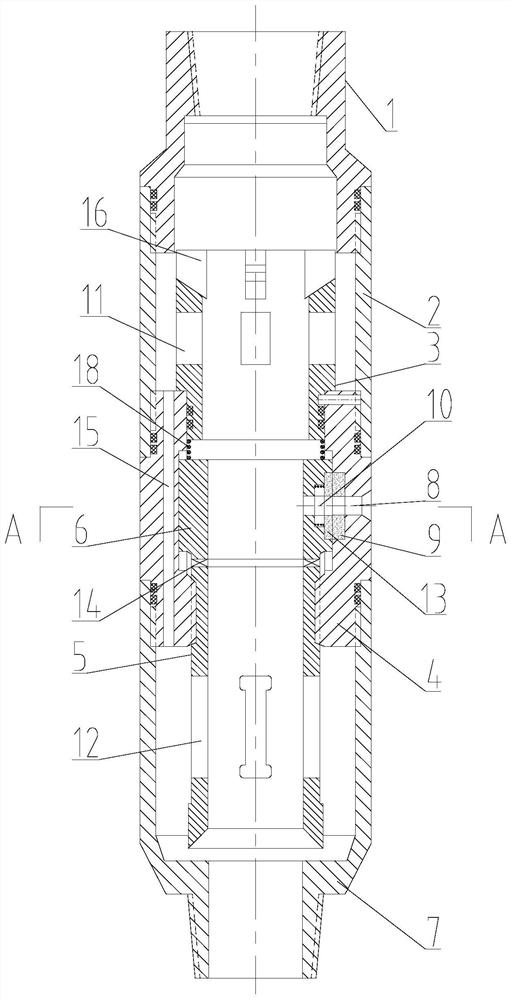

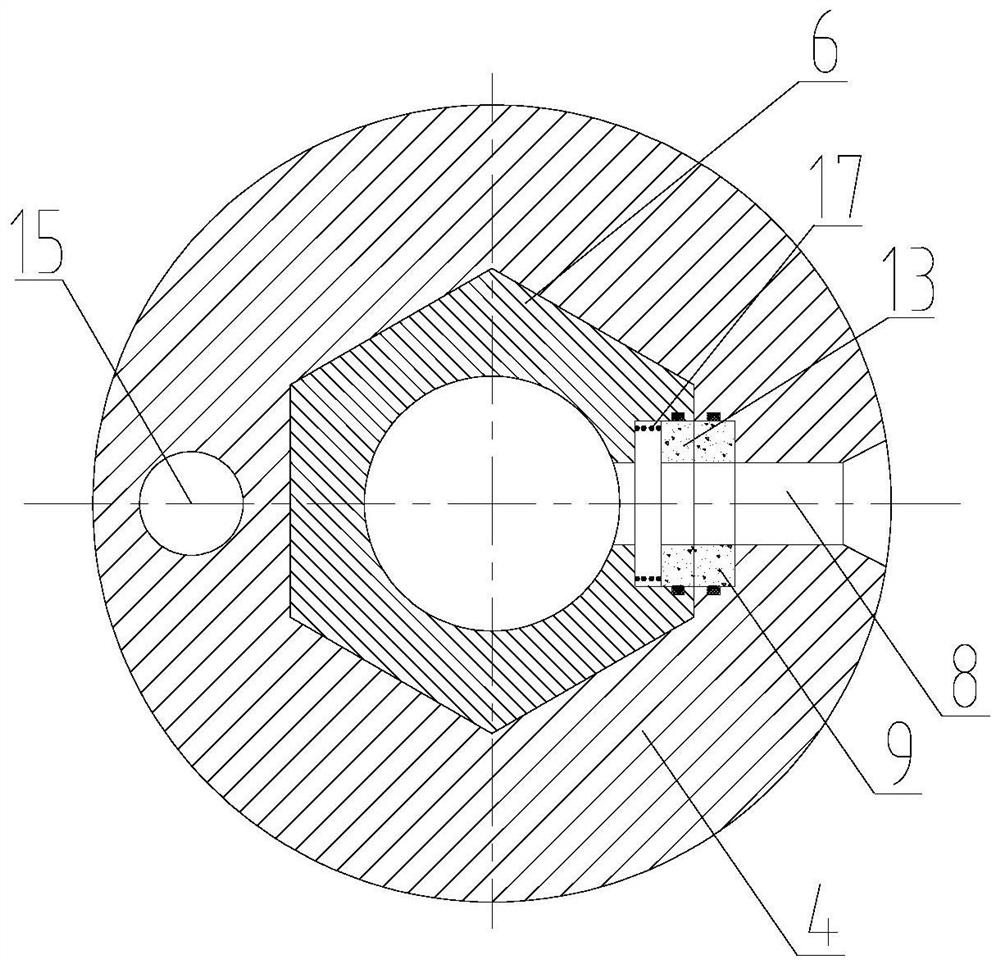

[0015] The present invention will be further described below in conjunction with accompanying drawing:

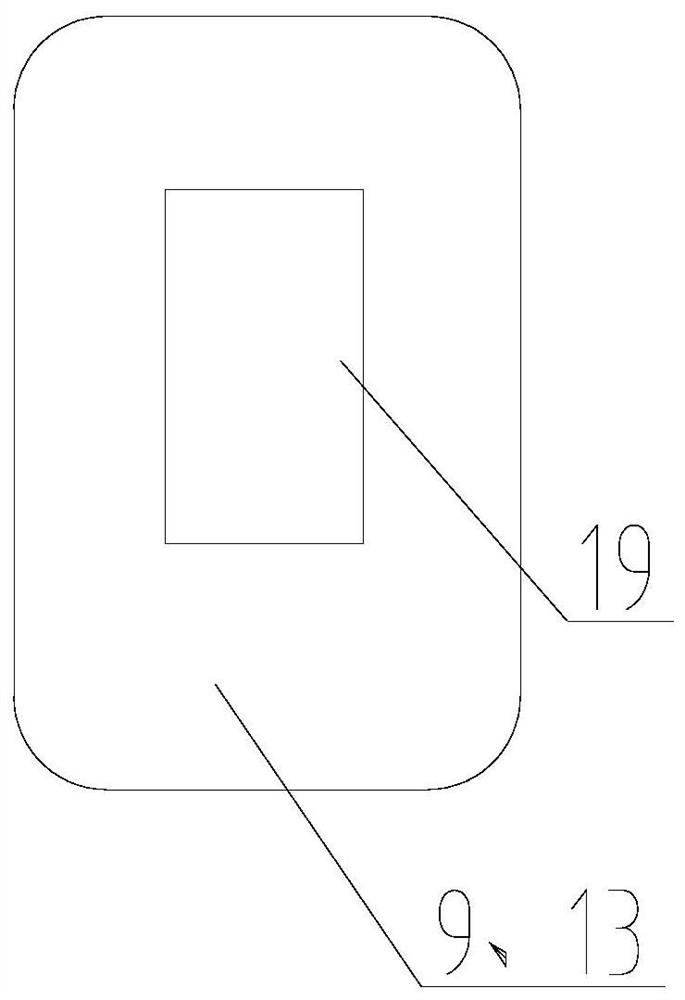

[0016] Depend on figure 1 to combine Figure 2~3 As shown, the dispenser includes an upper joint 1, the outer lower end of the upper joint 1 is connected to the casing 2, the inner lower end of the protective sleeve 2 is connected to the fixed water nozzle 4, the lower end of the fixed water nozzle 4 is connected to the lower joint 7 outside, and the fixed water nozzle 4 is the middle part The tube wall is provided with a casing with a radial water outlet 8, the inner side of the upper end of the fixed water nozzle 4 is screwed to the outer side of the lower end of the anti-rotation positioning cylinder 3, and the lower end of the fixed water nozzle 4 is screwed to the lifting pipe 5 through thread movement, and the upper side of the lifting pipe 5 The movable faucet 6 is connected through the plane bearing 14, and the lower part of the lifting pipe 5 is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com