Bridge type concentric water distributor

A water distributor and bridge-type technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of low success rate of instrument docking, inability to operate at the same time, low work efficiency, etc., and achieve high docking success rate , reduce workload and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

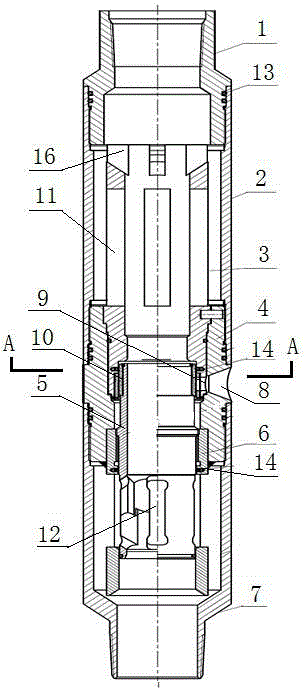

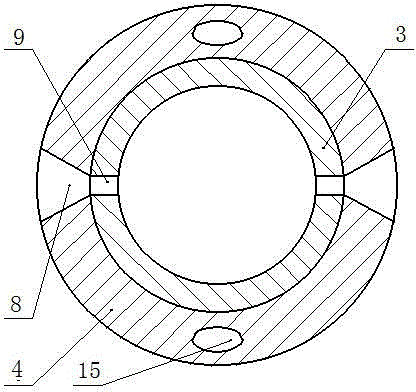

[0023] This embodiment provides a bridge-type concentric water distributor, such as figure 1 As shown, it includes an upper joint 1, the outer side of the lower end of the upper joint 1 is connected to the casing 2, the inner side of the lower end of the casing 2 is connected to the fixed faucet 4, and the outer side of the lower end of the fixed faucet 4 is connected to the lower joint 7, and the fixed faucet 4 is the middle pipe The wall is provided with a casing with a trumpet-shaped water outlet 8, the inner side of the upper end of the fixed water nozzle 4 is screwed to the outer side of the lower end of the anti-rotation positioning cylinder 3, and the lower end of the anti-rotation positioning cylinder 3 is provided with a radial water outlet opposite to the trumpet-shaped water outlet 8 9.

[0024] The inner side of the lower end of the fixed faucet 4 is fixed with the main cylinder 6, and the inner side of the main cylinder 6 is movably screwed to the movable faucet 5...

Embodiment 2

[0028] On the basis of Embodiment 1, this embodiment is further improved. In this embodiment, the fixed faucet 4 is provided with a bridge channel 15 along the axial direction, and the top of the anti-rotation positioning cylinder 3 is provided with a positioning groove, and the anti-rotation positioning A plurality of water-passing cutouts 11 are provided on the wall of the middle part of the cylinder 3 , and the water-passing cutouts 11 communicate with the bridge channel 15 of the fixed water nozzle 4 .

[0029] There is a positioning groove 16 at the top of the anti-rotation positioning cylinder 3, which cooperates with the positioning claw of the measuring and adjusting instrument to realize precise positioning. The upper part of the anti-rotating positioning cylinder 3 is provided with a number of water-passing cutouts 11, and the water-passing notches 11 are connected with the anti-rotation cam of the measuring and adjusting instrument. Cooperate to prevent the measuring...

Embodiment 3

[0031] In this embodiment, the structure in Embodiment 1 is further limited. The outer side of the upper part of the main body cylinder 6 is welded to the inner side of the lower part of the fixed faucet 4 in the form of welding. The middle part thread is connected, and the movable faucet 5 and the main cylinder 6 have the same axis.

[0032] Due to the complex downhole environment, there will be a lot of impurities and dirt, and the dirt will enter the thread along the gap under high pressure, causing thread corrosion and jamming. Therefore, in this embodiment, between the connecting surface of the upper joint 1 and the casing 2, the protective Between the lower end of the barrel 2 and the upper outer connection surface of the fixed faucet 4, and between the lower outer side of the fixed faucet 4 and the connection surface of the lower joint 7, the army is threadedly connected, and two O-rings 13 are provided on the connection surface , The rubber ring can protect the thread....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com