a dispenser

A dispenser and faucet technology, which is used in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of poor deployment accuracy, large workload, and increased workload, and achieve accurate and calculable metering flow. , High docking success rate and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

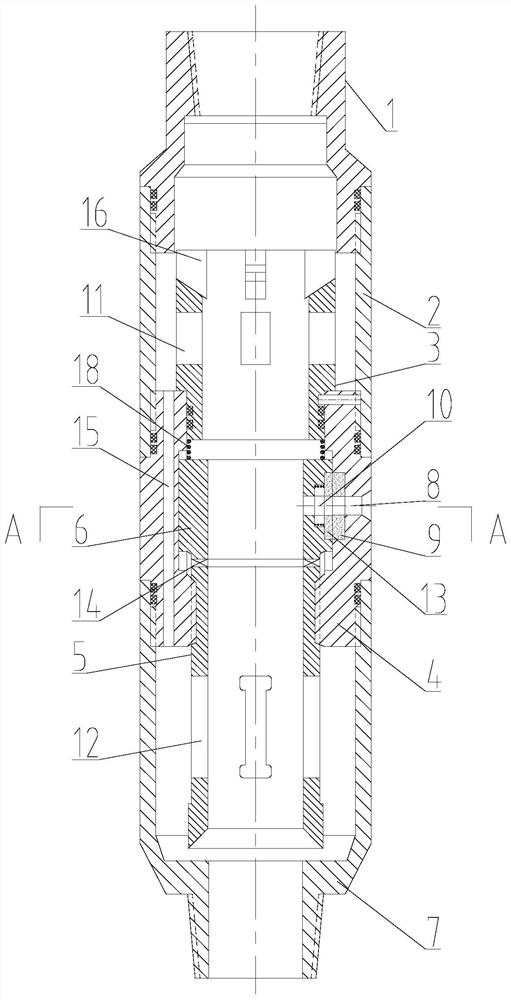

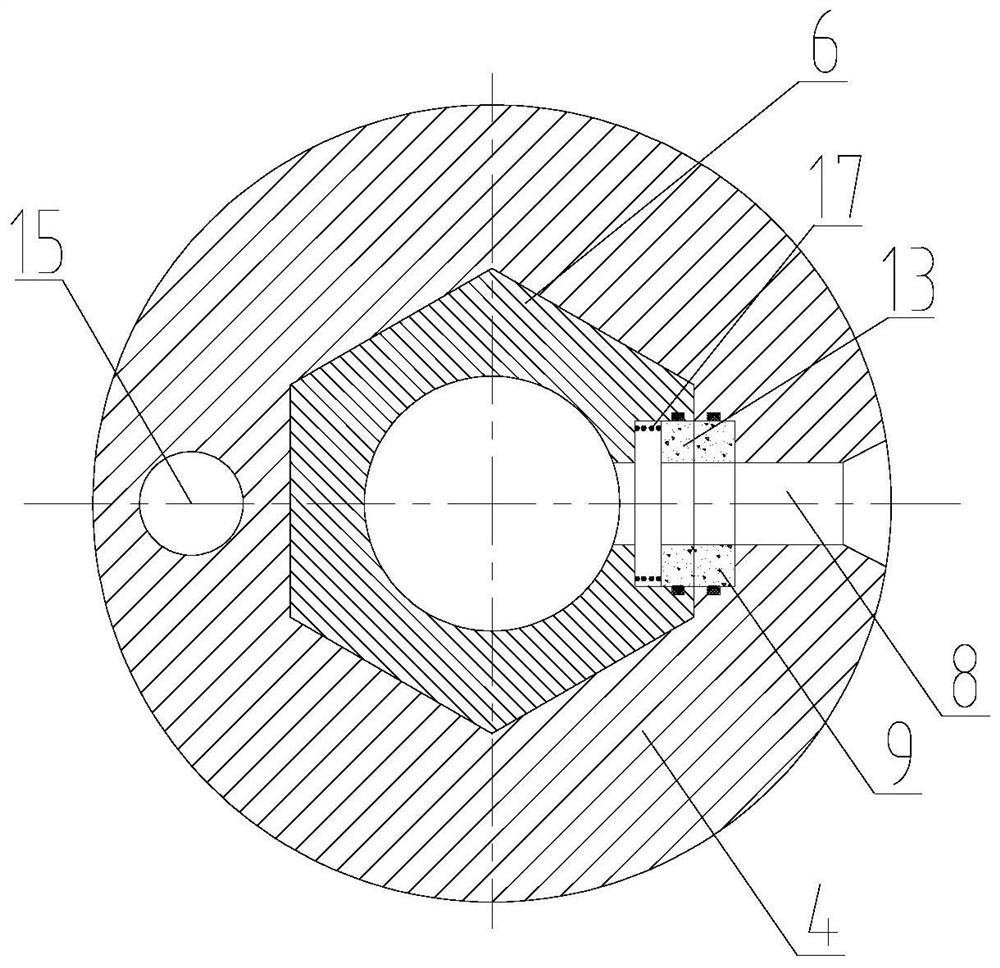

[0015] The present invention will be further described below with reference to the accompanying drawings:

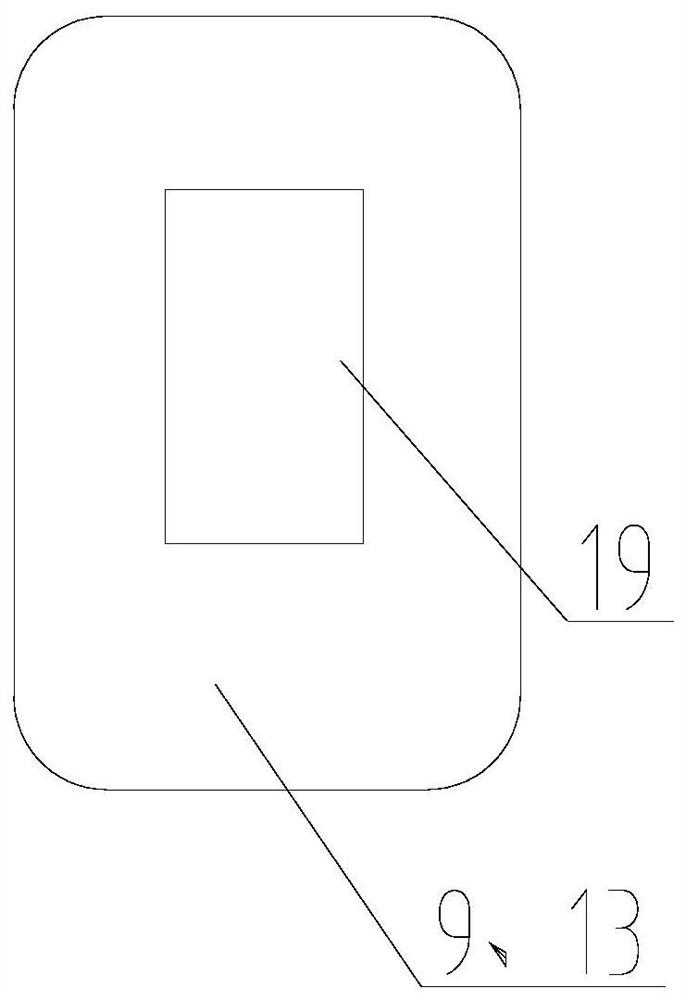

[0016] Depend on figure 1 Combine Figure 2 ~ 3 Shown, with injection, comprising an upper joint, a lower end of the outer connection joint casing 2, the lower end of the inner casing 2 is connected fixed tap 4, the connector 7 is connected the lower end of the fixed outer nozzle 4 is fixed to the central nozzle 4 radial wall of the outlet opening 8 of the sleeve, nozzle 4 is fixed inside the upper end of the lower end of rotary drum positioned outside relieve rotation 3, the lower end of the fixed nozzle 4 by a screw screwed active elevating pipe 5, the elevating pipe 5 side activities through the planar nozzle 14 is connected to a bearing 6, a lower portion of the elevating pipe 5 is provided with an adjustment slot 12;

[0017] 6 Tap activities hexagonal pillar shape, the movable nozzle 6 connected to a fixed mating hexagonal slot nozzle gap 4, the movable nozzle 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com