Method for calculating heat supply coal consumption and power supply coal consumption of a combined heat and power generation unit

A technology for combined heat and power generation units and coal consumption for power supply, which can be used in calculations, complex mathematical operations, and joint combustion mitigation, etc., and can solve problems such as inaccurate coal consumption for power generation, cost deviation, and high heating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

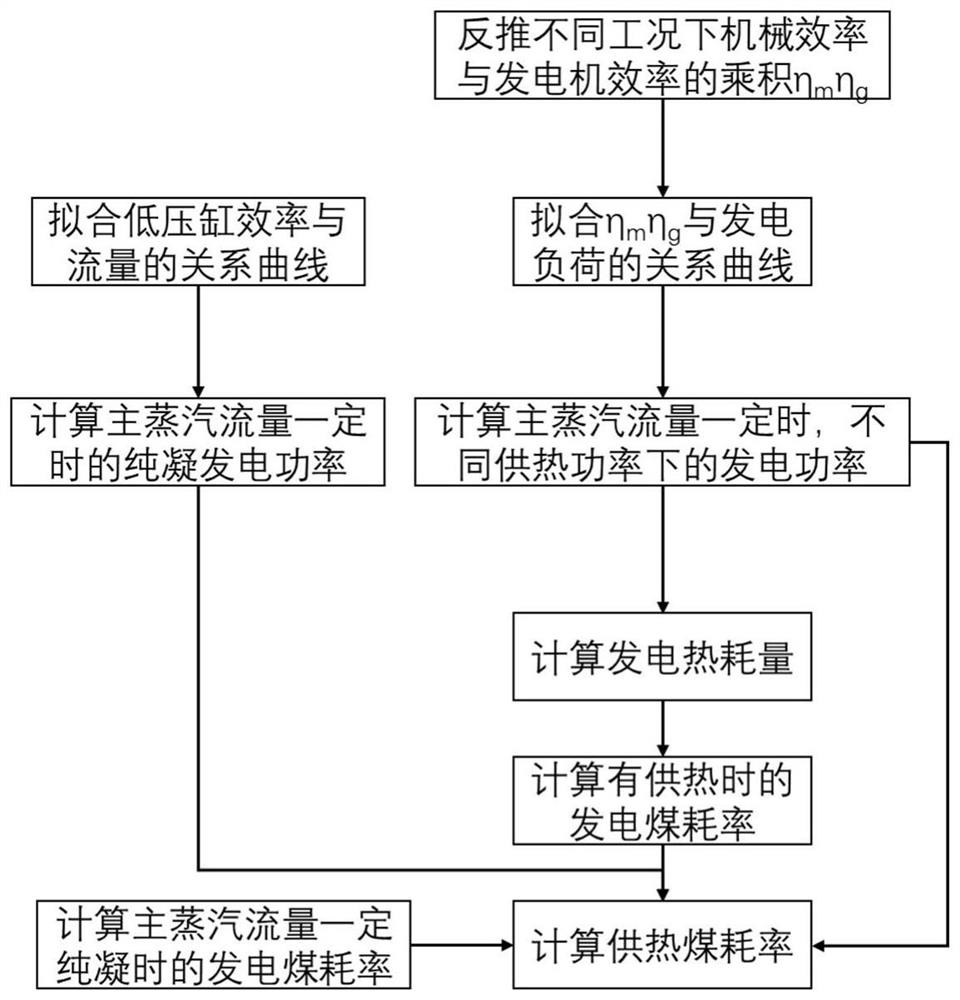

Method used

Image

Examples

Embodiment

[0103] The relevant parameters of a power plant are shown in Table 2:

[0104] Table 2. Full Load Calculation Parameters

[0105]

[0106]

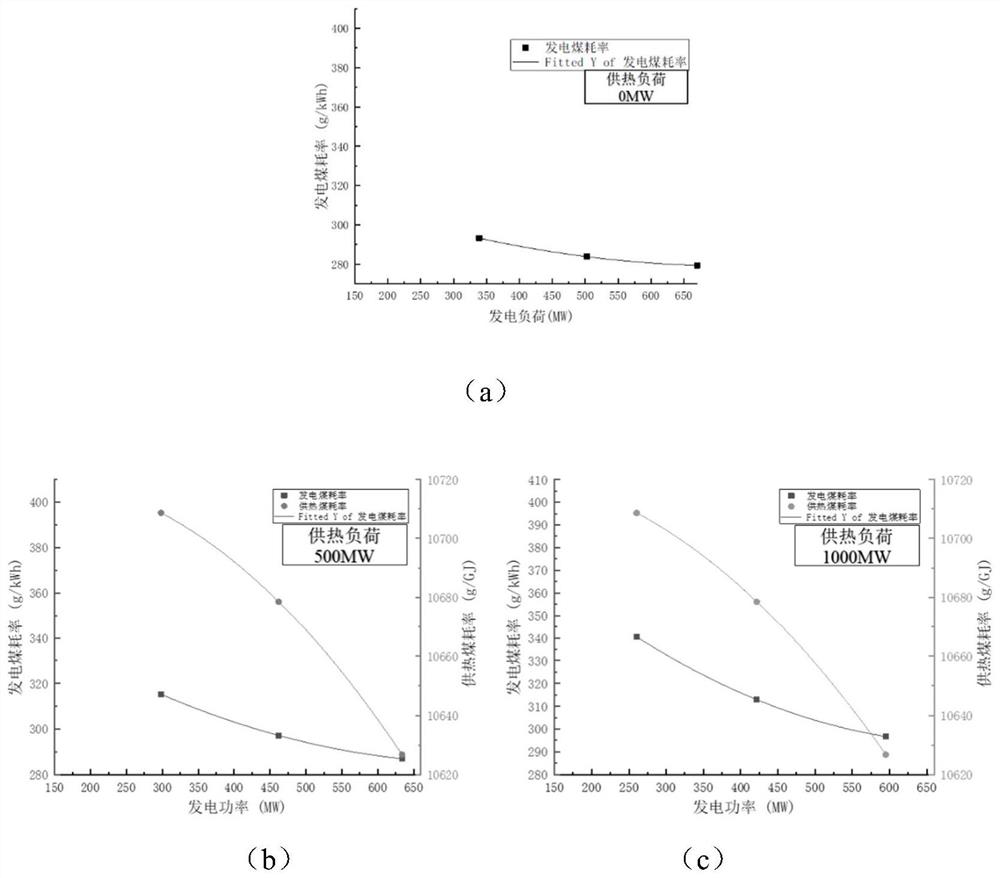

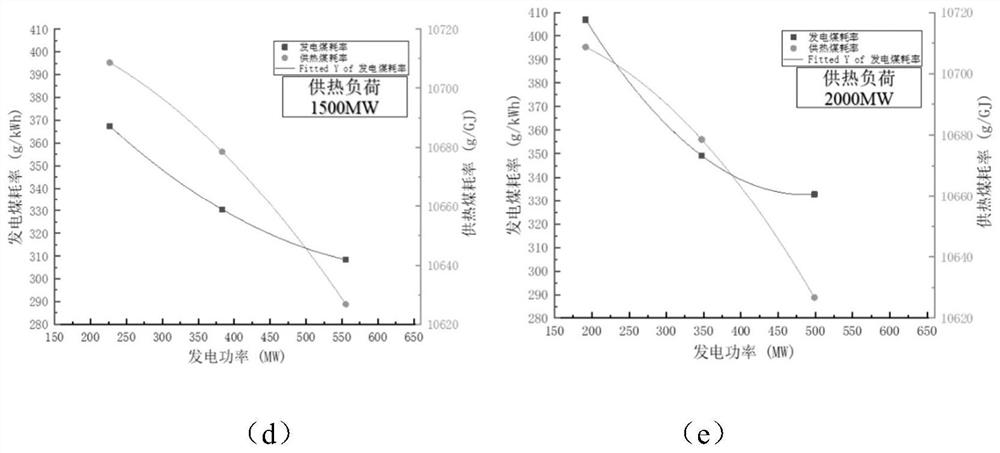

[0107] 1. Taking a cogeneration unit as an example, the pure condensing power of the unit is 670MW, and the corresponding main steam flow rate is 1865.5t / h. According to the low-pressure cylinder flow rate corresponding to the low-pressure cylinder efficiency in the steam turbine thermal characteristics book, the low-pressure cylinder efficiency curve is fitted as follows:

[0108] n l =(1.89503e-5F 2 +0.05062F+54.56328) / 100

[0109]2. Calculate the product of mechanical efficiency and generator power generation efficiency under 100%, 75%, 50%, and 40% load according to formula (3), expressed as η m n g They are: 0.981971813, 0.983555922, 0.980771111, 0.978230725, then fit η m n g The relationship curve with power generation load is:

[0110] n m n g =(8.07676e-6P 2 +0.00849P+96.13123) / 100)

[0111] 3. Therefore, accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com