Joint storage material multi-factory balanced stock utilization method and system

A material and factory technology, applied in the field of storage and management of production materials, can solve problems such as poor information interaction, serious fund backlog, large inventory of power companies, etc., to enhance auxiliary decision-making capabilities, solve cost collection problems, and optimize production material inventory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

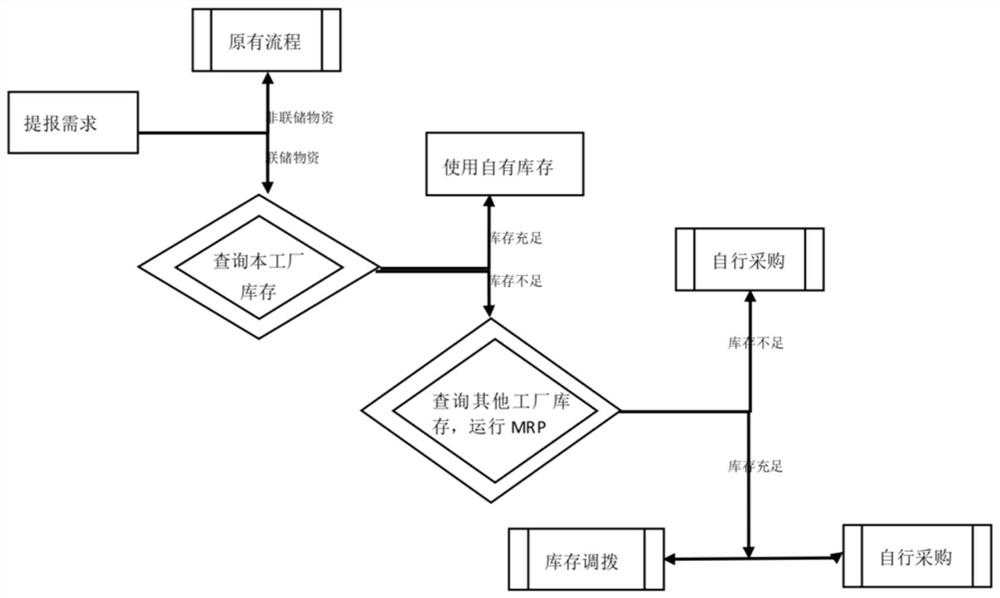

[0031] Such as figure 1 As shown, the multi-factory balance profit warehouse method for federated materials of the present invention, the process is as follows: when the user has a demand for federated materials, first of all, report the demand to the information system, and the information system will judge whether the materials are federated materials, if not Fed supplies will follow the original inventory allocation process. If the material is a Fed material, check the factory inventory. If the inventory is sufficient, use the self-owned inventory, if the inventory is insufficient, query the inventory of other factories and run MRP. If other stocks are insufficient, they will purchase by themselves. If the factory has sufficient stocks, they will transfer stocks from the factory. According to the actual situation, they can also choose to purchase by themselves. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com