Photosensitive imaging assembly of camera

A technology for imaging components and cameras, which is applied to components of color TVs, components of TV systems, electrical components, etc., and can solve problems such as poor imaging quality of image sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

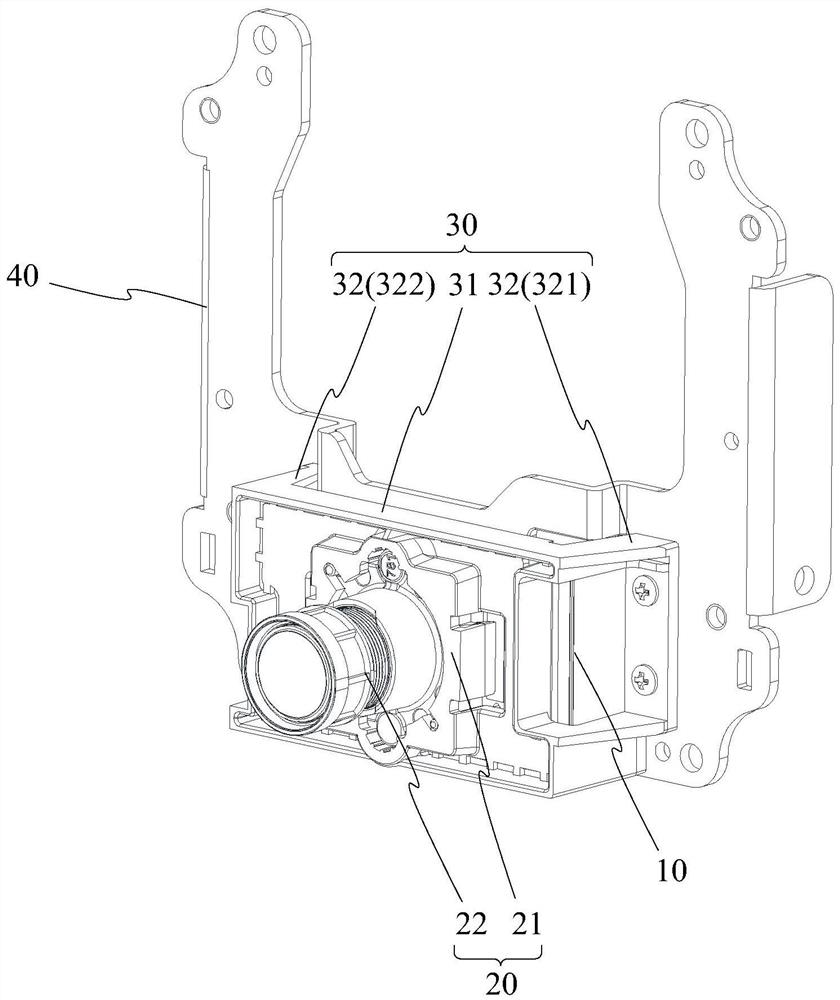

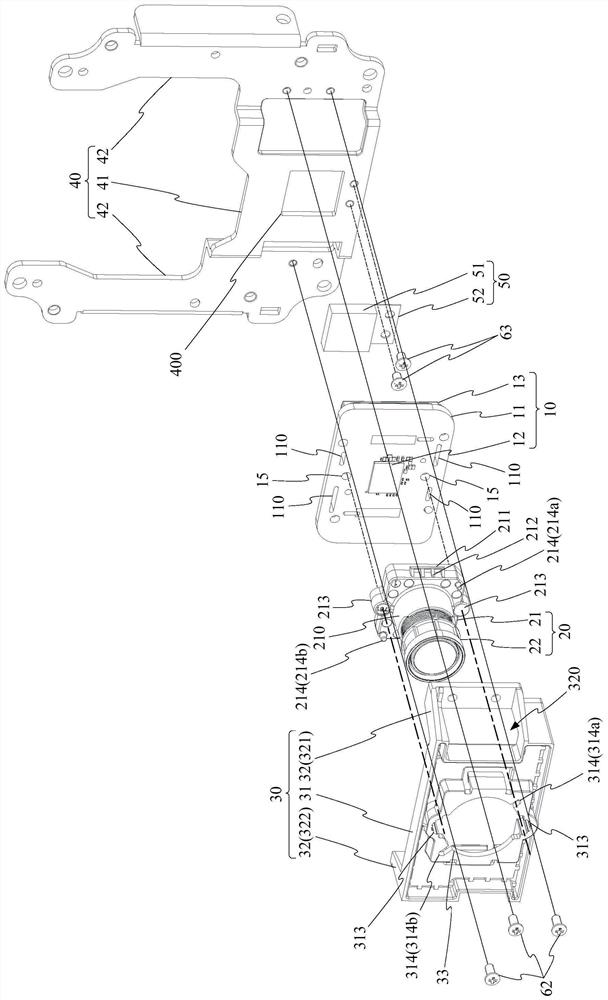

[0093] figure 1 It is a schematic diagram of the assembly structure of the photosensitive imaging component of the camera in one embodiment. figure 2 For such figure 1 Schematic diagram of the exploded structure of the photosensitive imaging component shown. See figure 1 and combine figure 2 , in this embodiment, the photosensitive imaging component of the camera may include:

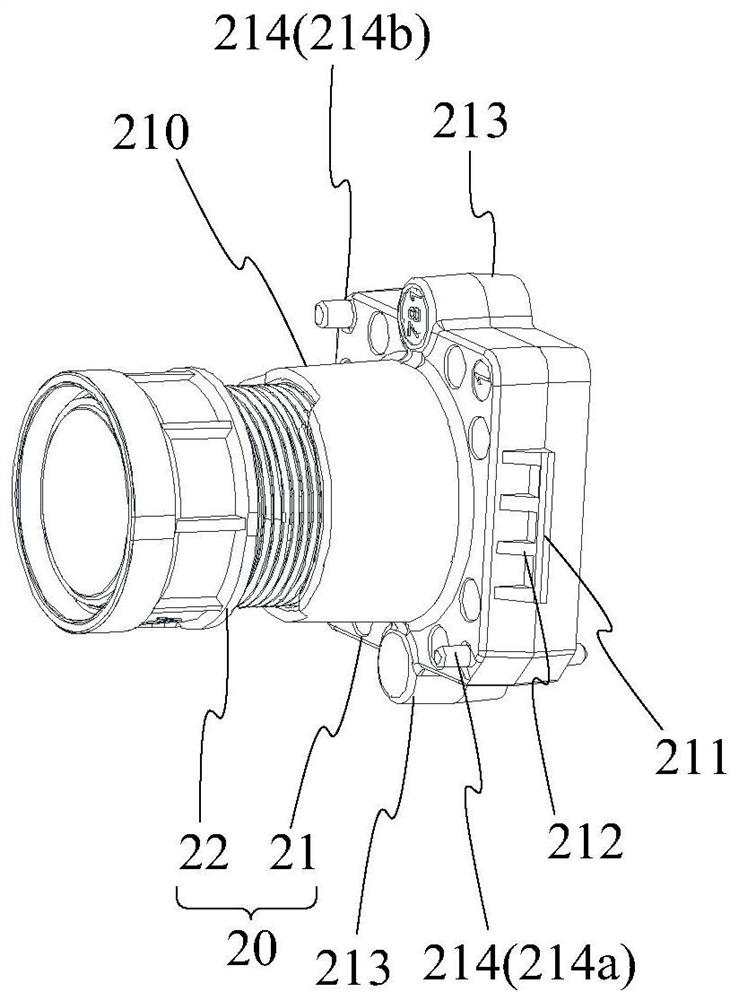

[0094] An imaging module 10, the imaging module 10 may have a circuit board 11 and an image sensor 12 arranged on the circuit board 11 (for example, the image sensor 12 may be located on the front surface of the circuit board 11 when placed vertically);

[0095] A lens module 20, the lens module 20 can have a mirror base 21 and a lens 22 installed on the mirror base 21, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com