Subframe Mounting Bush Structure And Vehicle

A subframe and bushing technology, applied in the substructure, superstructure, vehicle parts, etc., can solve the problems of increased on-site claims, complex structures, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

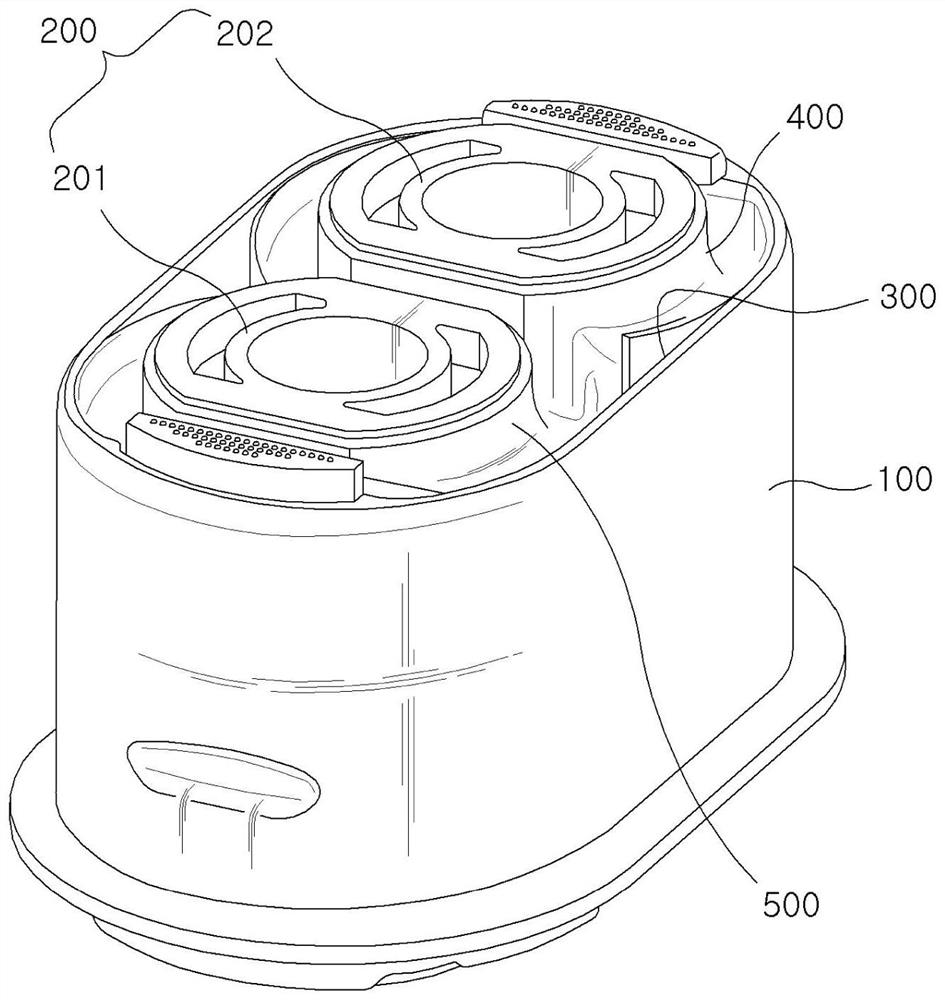

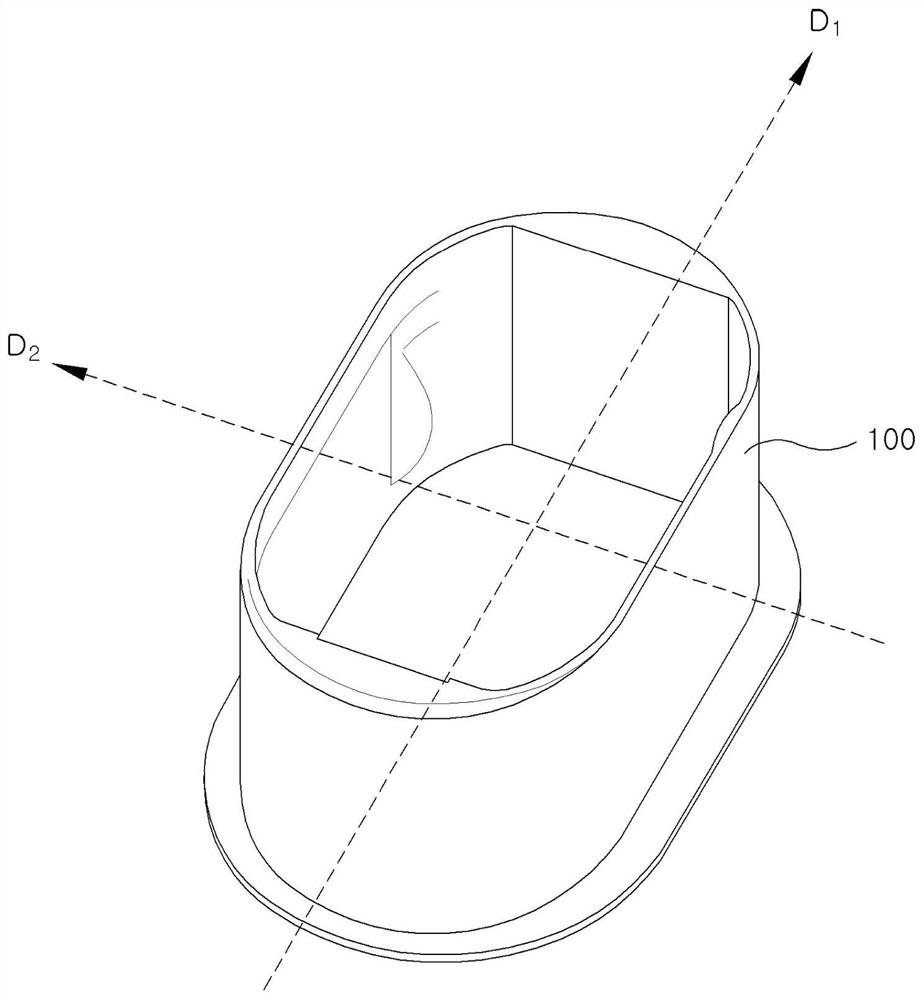

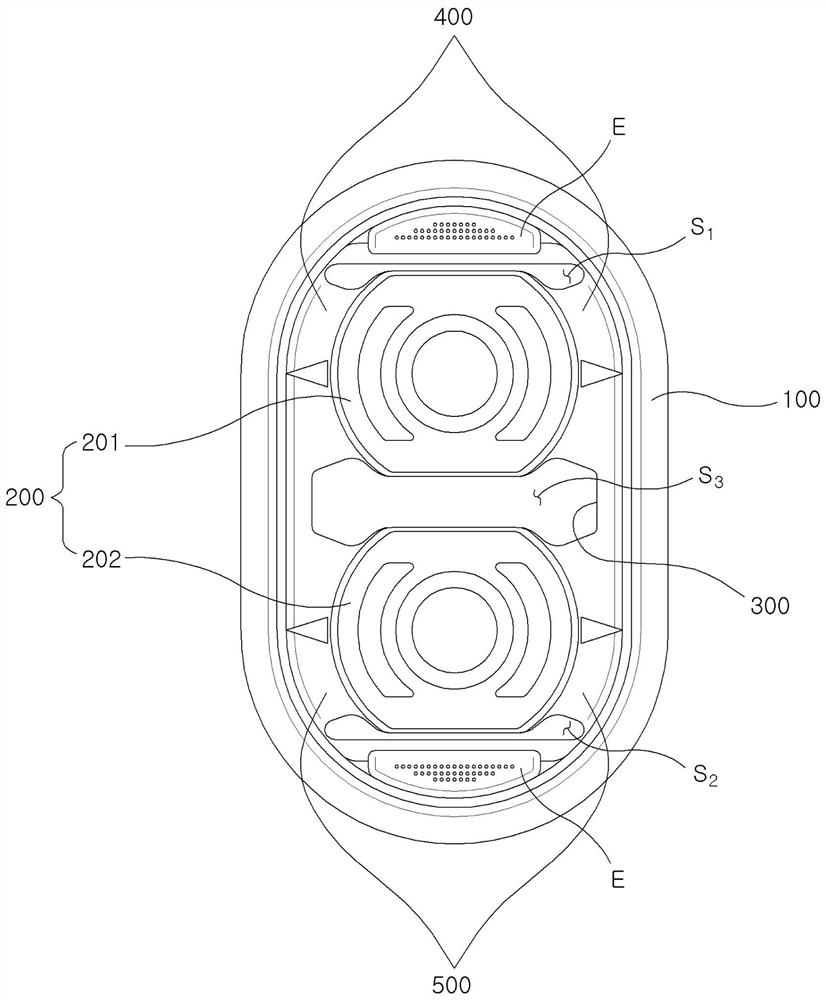

[0030] Hereinafter, a subframe mounting bush structure for improving NVH performance according to an embodiment of the present disclosure will be described with reference to the accompanying drawings.

[0031] The subframe mounting bushing structure for improving NVH performance according to an embodiment of the present disclosure has the following features: the housing 100 is formed such that the length in the width direction ( D1 ) is longer than the length in the length direction ( D2 ), and the housing 100 provides Two or more inner casings 200 are formed, two or more bridges 400, 500 for fixing the two or more inner casings 200 are formed in the outer casing 100, and the stiffness of the two or more bridges 400, 500 is mutually same.

[0032] Such as Figure 1 to Figure 7 As shown, in the embodiment, two inner shells 200 are arranged in the outer shell 100 and a total of two bridges 400 , 500 are also arranged therein. Unlike what is shown, two or more inner cases 200 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com