Cutting machine for cutting aerated concrete slabs

A technology of aerated concrete slabs and cutting machines, applied in the field of aerated concrete, can solve the problems of low cutting efficiency and time-consuming aerated concrete slabs, and achieve the possibility of improving cutting efficiency, saving time, and reducing displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-7 The application is described in further detail.

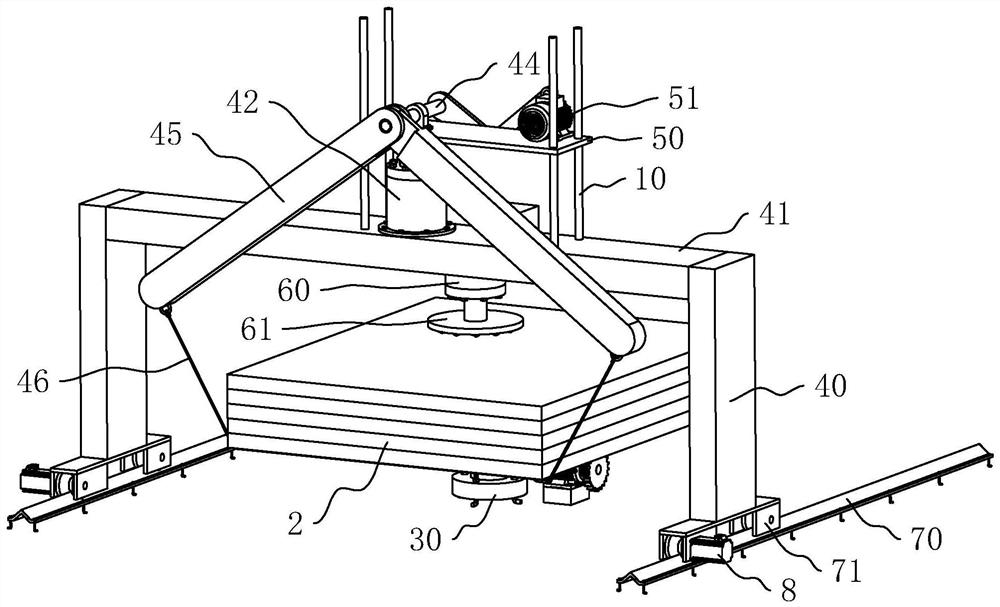

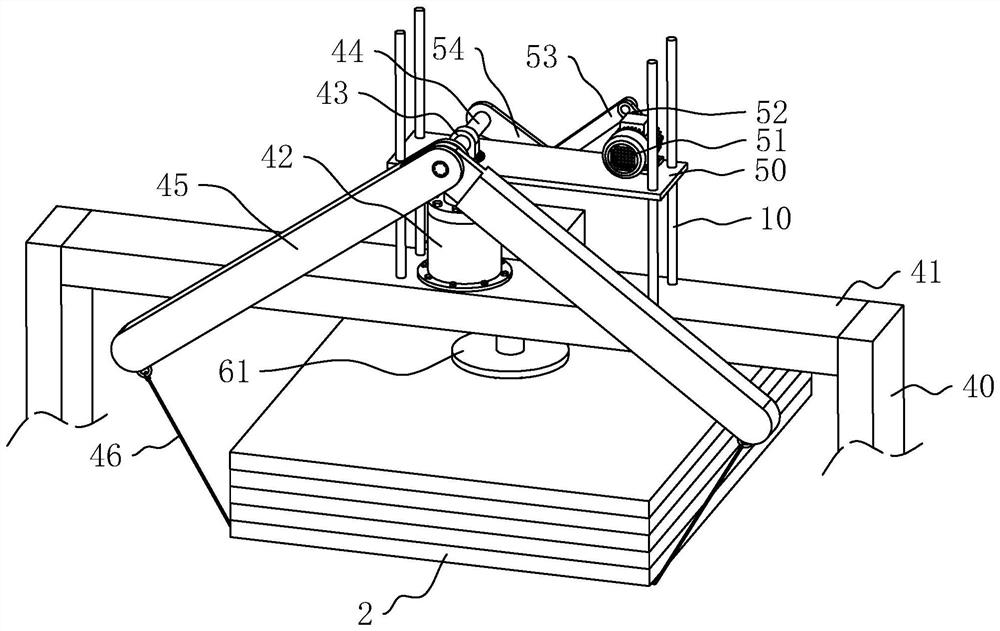

[0039] The embodiment of the present application discloses a cutting machine for cutting an aerated concrete slab. refer to figure 1 with figure 2 The cutting machine for cutting the aerated concrete slab includes a cutting table 1 for placing the aerated concrete slab 2, a driving device for driving the cutting table 1 to rotate, and a cutting machine for cutting the aerated concrete slab 2. A cutting device, a displacement device for adjusting the position of the cutting device.

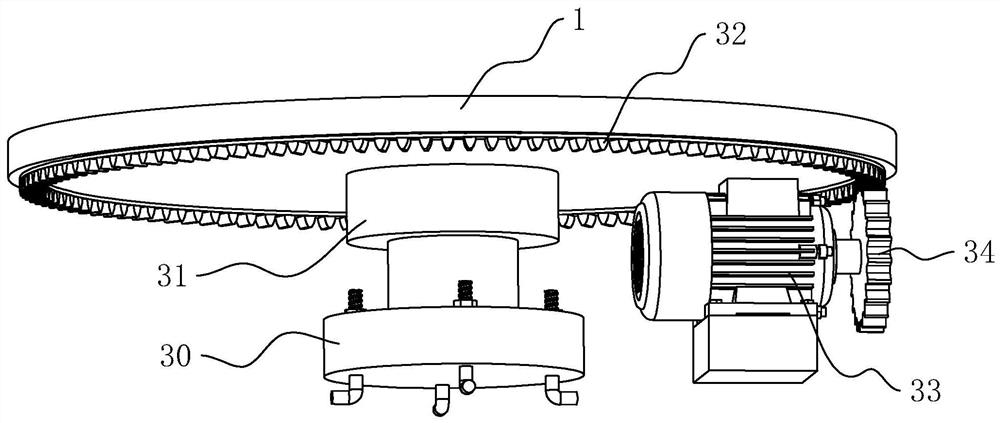

[0040] refer to figure 1 with figure 2 , the cutting table 1 is placed horizontally and its cross section is circular, and the driving device is located below the cutting table 1 . The driving device includes a fixed seat 30 and a first motor 33 connected to the ground by pre-embedded anchor bolts, a gear 34 fixedly sleeved on the output shaft of the first motor 33, a rotation sleeve mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com