Split type two-shaft driving mechanism

A driving mechanism and shaft-driven technology, which is applied in the field of satellite technology, can solve problems such as the inability to guarantee the incident angle of sunlight, product stability, inheritance, poor versatility, and heavy weight, and achieve high reliability, good inheritance, and The effect of simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

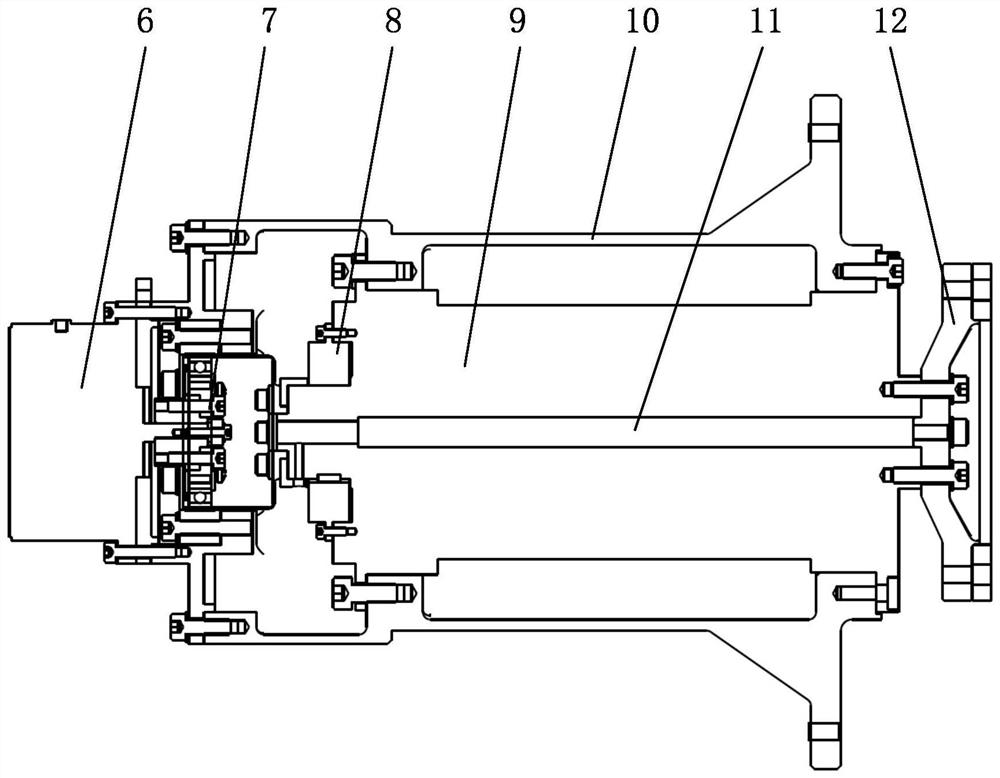

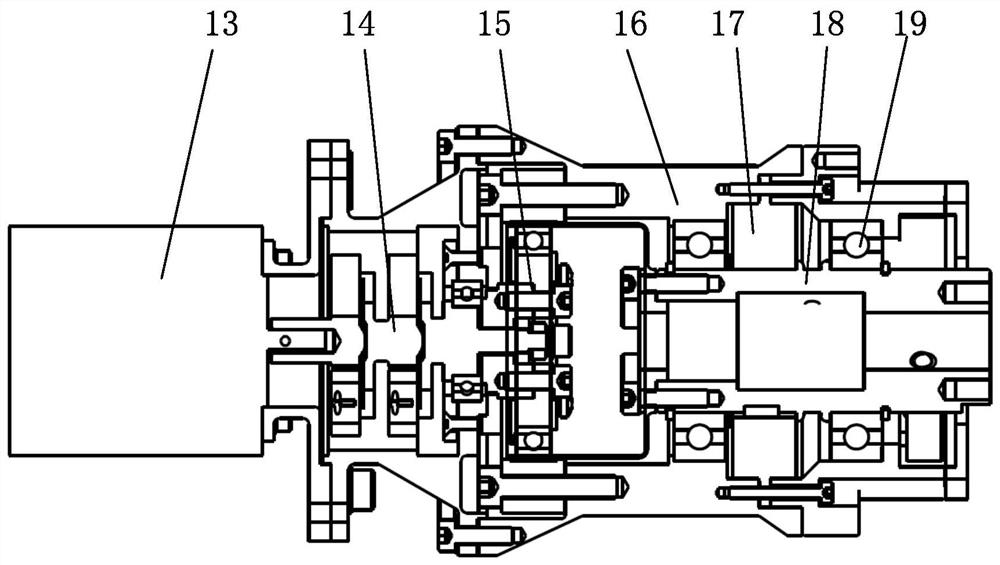

[0029] A split-type two-axis driving mechanism proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

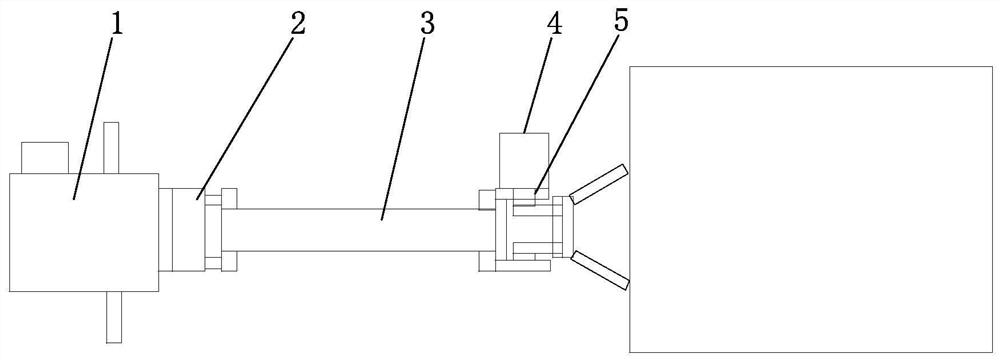

[0030] see figure 1 , a split-type two-axis driving mechanism, including an A-axis driving mechanism 1, a root hinge 2, an unfolding arm 3, a B-axis driving mechanism 4, and a connecting frame 5;

[0031] Among them, the A-axis drive mechanism 1 and the B-axis drive mechanism 4 adopt a split design, and the A and B-axis drive mechanisms 4 can fully inherit the existing mature single-axis drive mechanism technology status, with high product maturity, simple configuration, and reliability. High, the A-axis drive mechanism 1 is connected to the B-axis drive mechanism 4 through the root hinge 2 and the deployment arm 3, which improves the integration of the drive mechanism and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com