Assembly line flame disinfection device

A disinfection device and assembly line technology, applied in food science, food preservation, application, etc., can solve the problems of limited time limit, heavy manual labor, and intolerable environmental smell on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

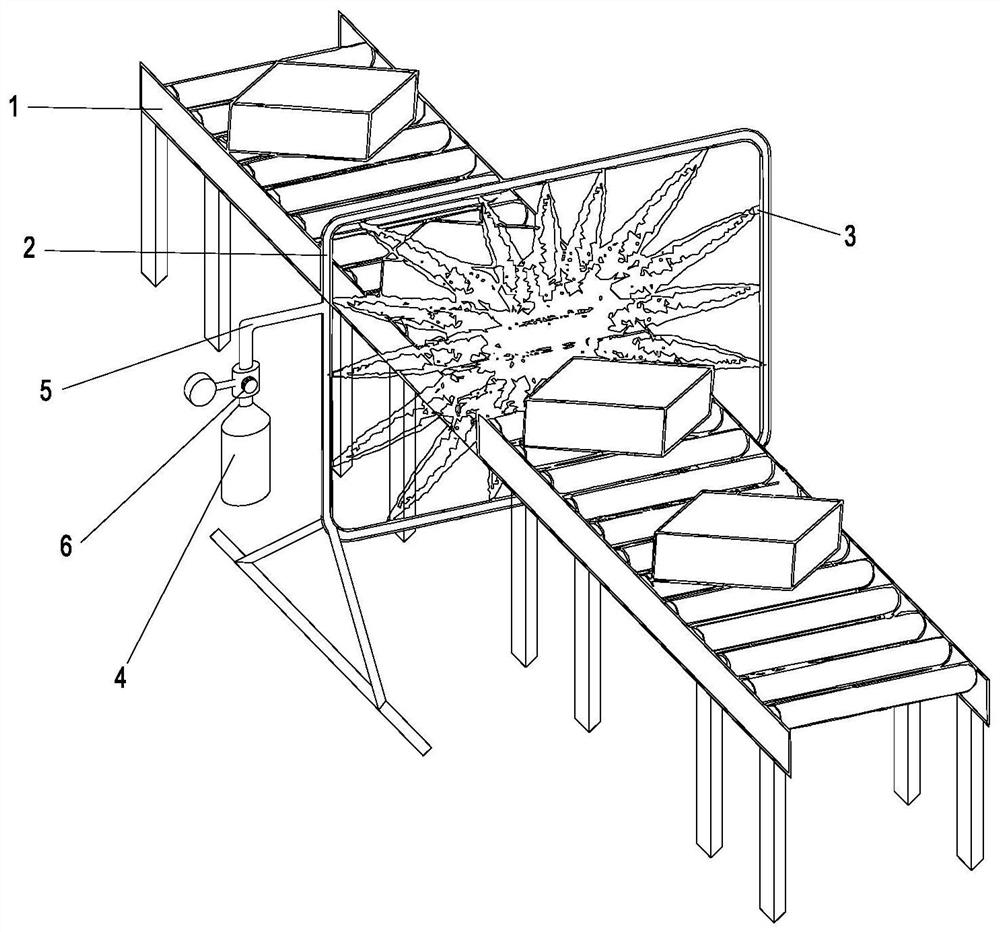

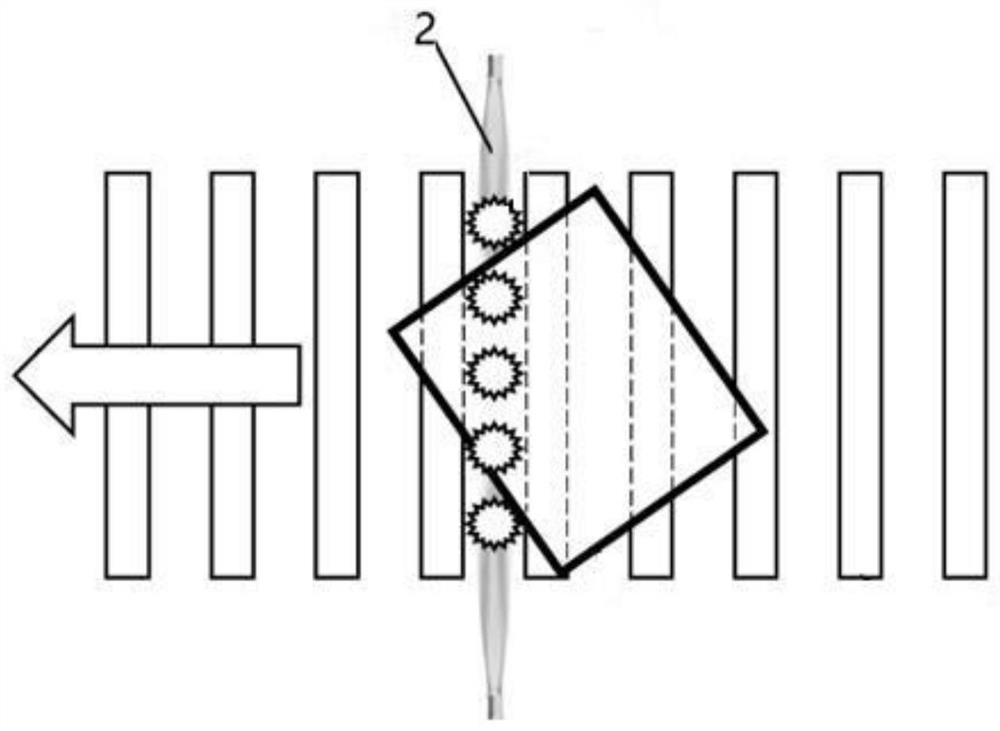

[0019] Such as Figure 1-3 As shown in one of the present invention, an assembly line flame disinfection device of the present invention includes a conveying device 1 and a flame spray gun array, the flame spray gun array includes an annular gas distribution pipe 2, the gas distribution pipe 2 surrounds the outside of the conveying device A plurality of spray guns 3 are connected at intervals on the pipe wall of the pipe 2, and the flame injection direction of each spray gun 3 points to the transmission device 1 respectively, and the air inlet of the gas distribution pipe 2 is connected to the gas source; The flames form a densely woven flame curtain.

[0020] The gas source includes a gas tank 4 and a gas delivery pipe 5 , the gas outlet of the gas tank 4 is connected to the gas inlet of the gas distribution pipe 2 through the gas delivery pipe 5 , and a pressure control valve 6 is connected to the gas delivery pipe 5 . Each spray gun 3 is connected with an air flow valve (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com