Disinfecting and killing module of cleaning robot

A cleaning robot and host technology, applied in the field of cleaning robots, can solve the problems of external environmental pollution, difficult dust and dirt cleaning, breeding of bacteria, etc., and achieve the effect of improving the disinfecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

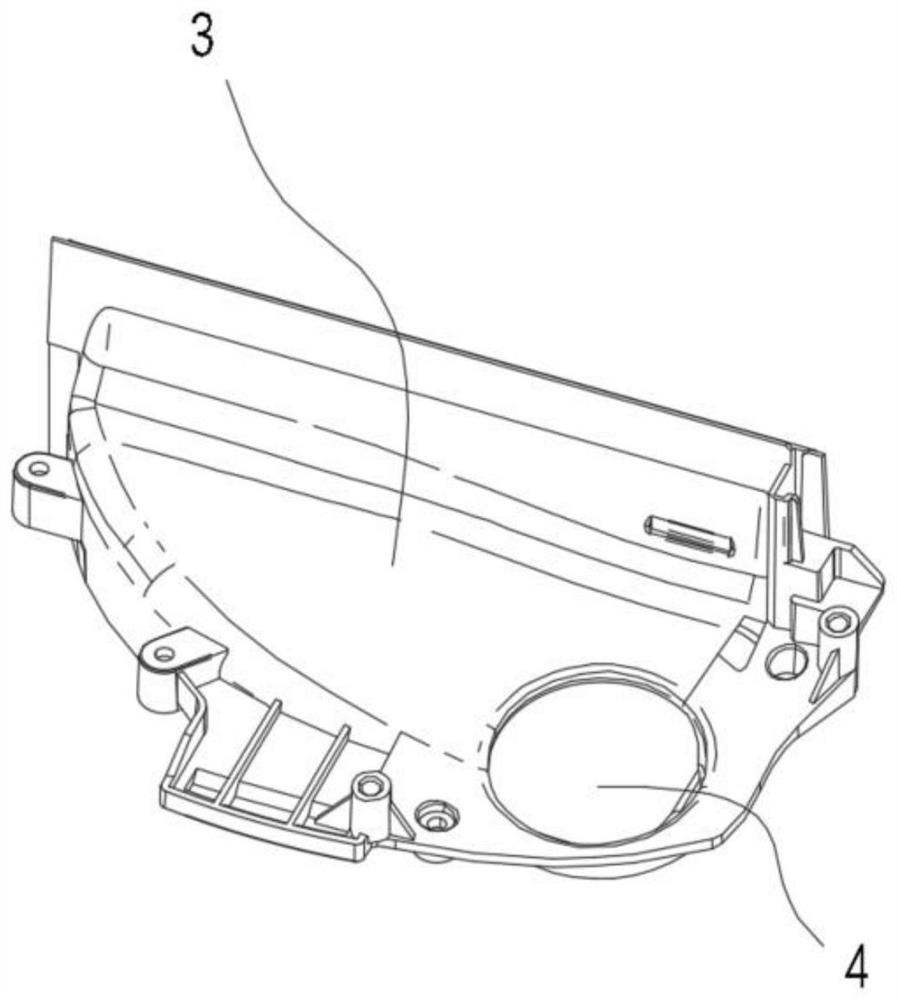

[0040] Such as Figure 6-7 As shown, the disinfecting element 7 is arranged on the air duct element 3. The disinfecting element 7 includes a main body element 13 and two groups of emitters protruding from the main body element 13. The main body element 13 includes electronic components such as necessary circuit boards and ion generating devices. Components also include sockets that connect to circuits in the host, etc. The two groups of emitters are positive emitter 10 a and negative emitter 11 a respectively, and the two groups of emitters are located in the air duct cavity 5 . disinfecting element 7 main parts are arranged on the outside of air duct assembly 3, and its main body element 13 is also provided with socket 8 and is connected with cleaning robot internal circuit (in the illustration of embodiment 2 and 3, socket 8 is not drawn, the actual This socket can be set as required).

[0041] Such as Figure 7 As shown, the two groups of emitters are separated by a separa...

Embodiment 2

[0043] In Embodiment 1, the disinfecting element 7 and the emitter are integrally structured, which results in the need to set a larger opening on the inner wall of the air duct cavity 5 of the air duct assembly, and at the same time, a partition with a larger area is provided in the air duct cavity 5 The plate affects the gas flow inside the air duct cavity. Therefore, this embodiment proposes a new arrangement of disinfecting components.

[0044] Such as Figure 8-9 As shown, the disinfecting element 7 includes a main body element 13, a positive emitter head 14 and a negative emitter head 15 which are separated from each other, and a mounting seat 12 is arranged on the outer wall of the air duct element 3, and the mounting seat 12 is a corresponding main body element 13 1. The cavity structure provided by the positive emitter 14 and the negative emitter 15, the main body element 13, the positive emitter 14 and the negative emitter 15 are all arranged in the mounting seat 12, a...

Embodiment 3

[0047] The main difference between this embodiment and embodiment 2 is that, on the basis of embodiment 2, the cleaning robot of this embodiment has the function of discharging the dirt accumulated in the dust box 2 to a unified recycling bin. like Figure 10-12 As shown, on the bottom plate of the main body 1 of the machine, a discharge channel 16 is provided. One end of the discharge channel 16 opens into the dust box 2, and the other end opens to the side wall of the main body. When in use, the cleaning robot moves to the recycling station, and the side The opening on the wall is docked with the opening of the recycle bin, the power unit in the recycle bin is started, and the dirt in the dust box 2 enters into the recycle bin through the discharge channel 16 . A cleaning robot with an emptying station is relatively well known in the art, and the relevant technical details of opening docking and switching are not described in detail here.

[0048] In this embodiment, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com