Fire fighting device for a chemical plant

A technology for fire-fighting devices and chemical plants, which is applied to cleaning methods and utensils, chemical instruments and methods, and grain processing. Avoid the effect of dry powder coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

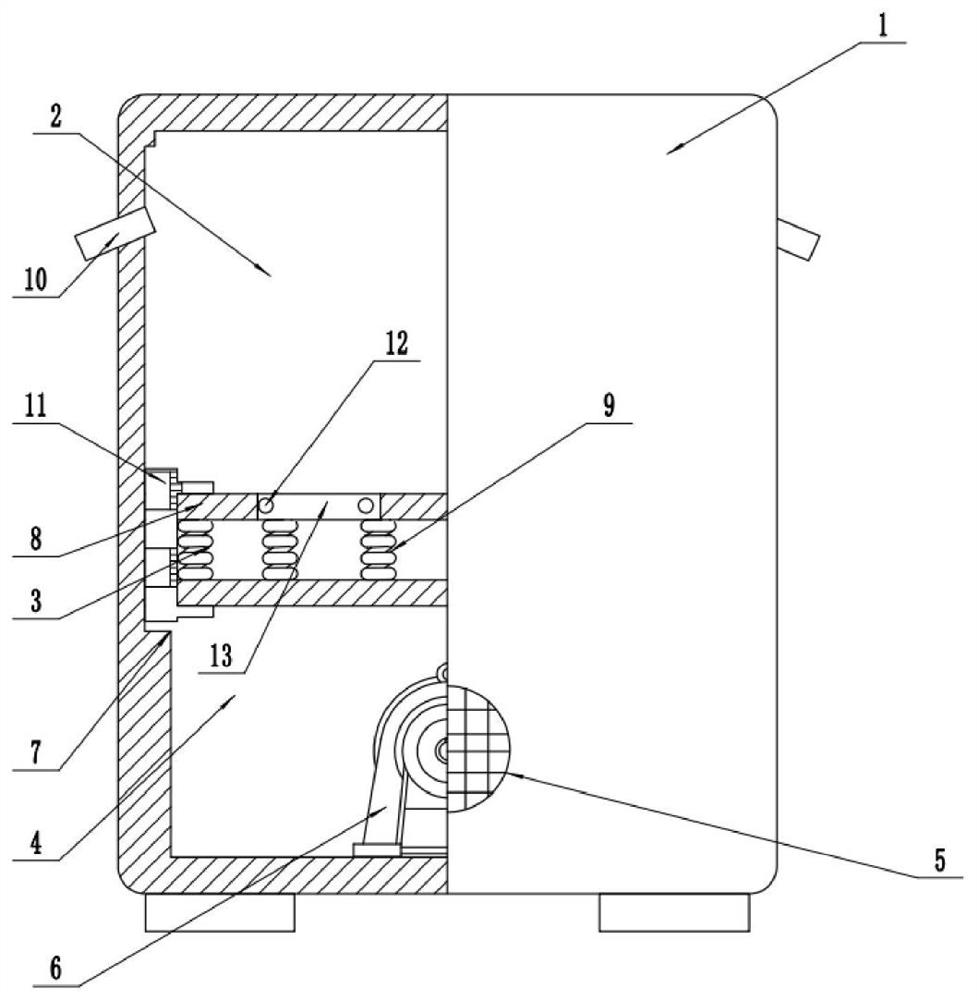

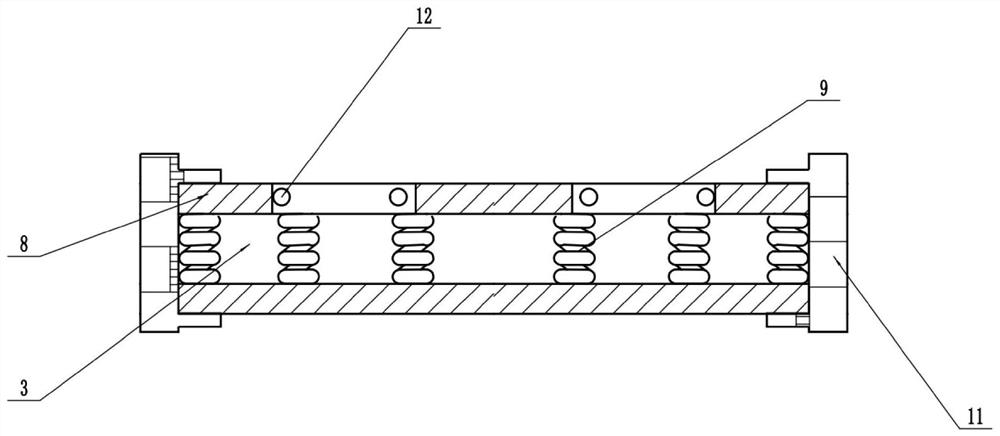

[0022] The reference signs in the drawings of the specification include: cabinet body 1, dry powder filtration layer 2, vibration layer 3, negative pressure suction layer 4, opening 5, negative pressure machine 6, limit edge 7, slide plate 8, tension spring 9 , Nozzle 10, rubber layer 11, steel ball 12, rolling chamber 13.

[0023] The embodiment is basically as attached figure 1 As shown: a fire fighting device for a chemical plant includes a column-type cabinet body 1, and the cabinet body 1 sequentially includes a dry powder filter layer 2, a vibration layer 3, and a negative pressure suction layer 4 from top to bottom, and the negative pressure suction layer 4 Including opening 5, negative pressure machine 6 and smoke sensor. The opening 5 is located on the surface of the column-type cabinet body 1, a storage chamber is formed between the opening 5 and the cabinet body 1, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com