Patents

Literature

45results about How to "Realize the transportation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

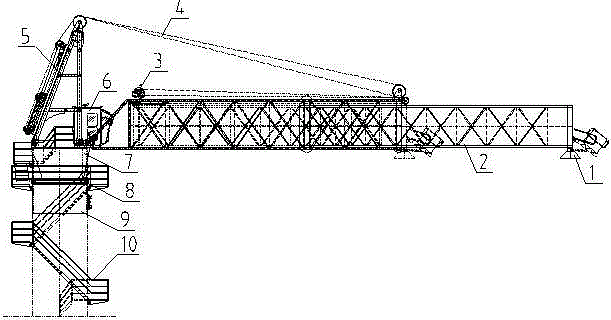

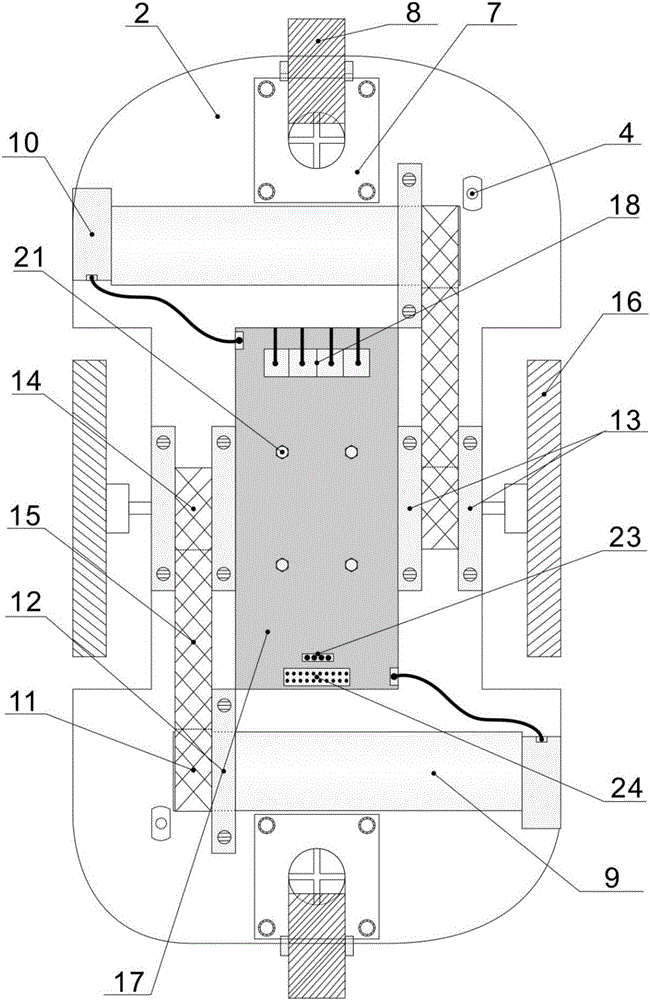

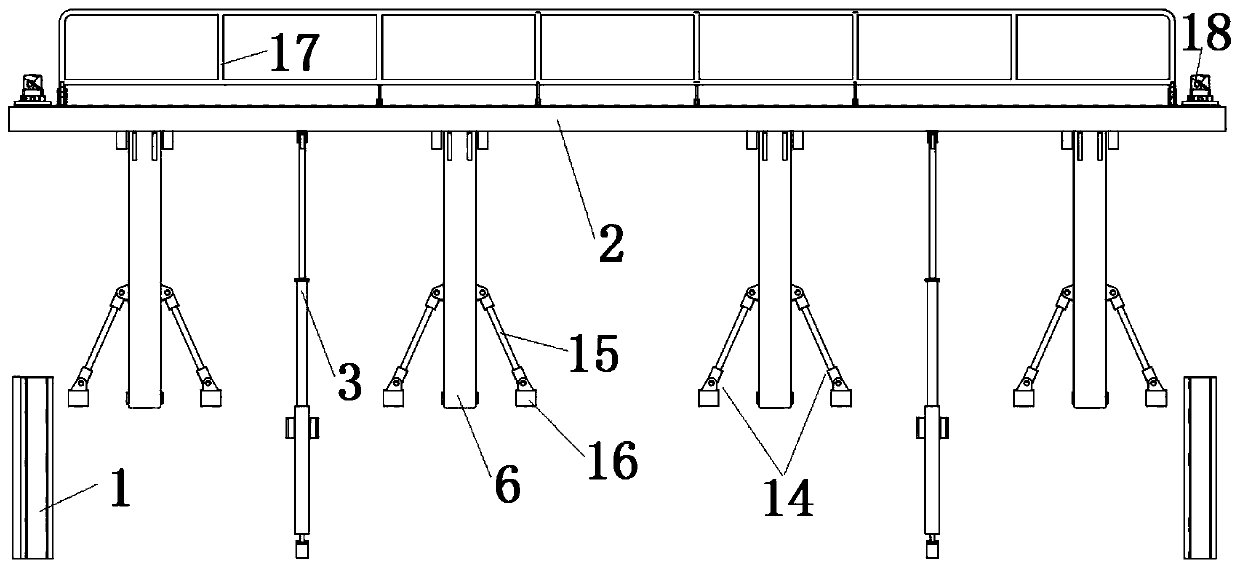

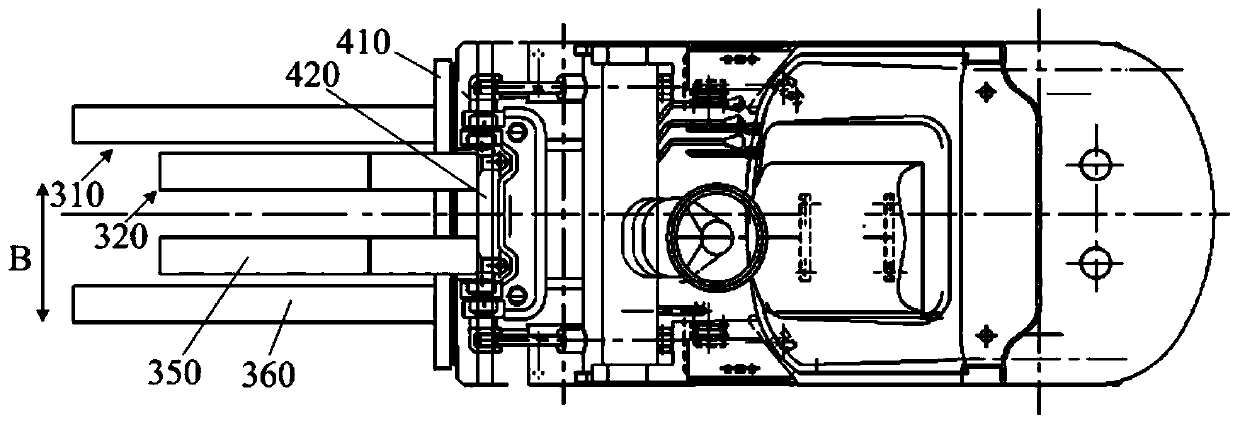

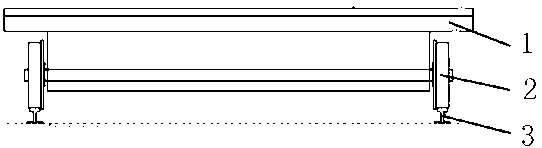

Gangway bridge device

InactiveCN104627325ARealize transportationReasonable structure layoutCargo handling apparatusPassenger handling apparatusMarine equipment

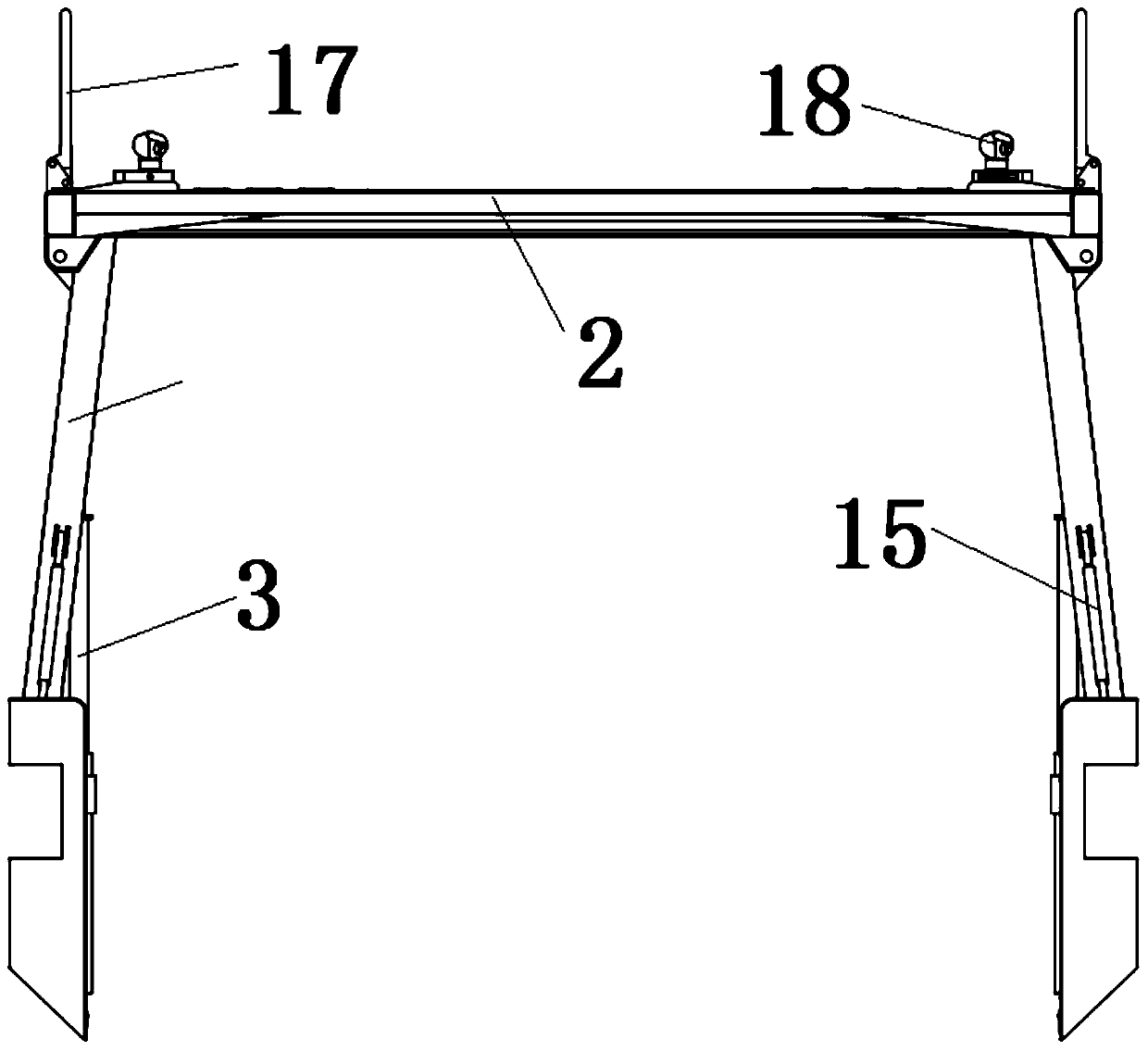

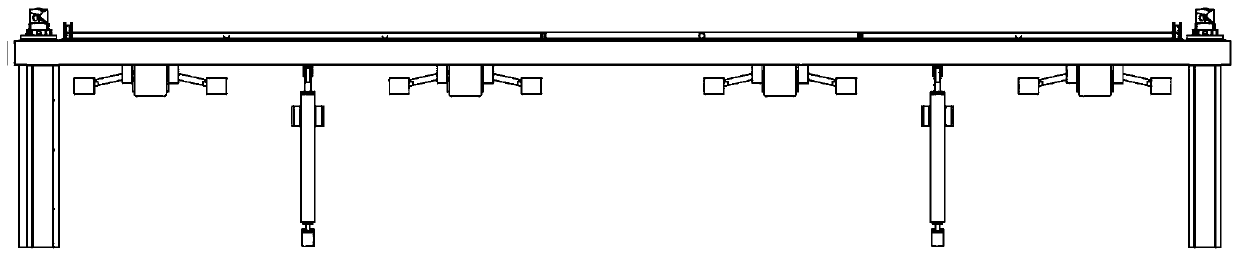

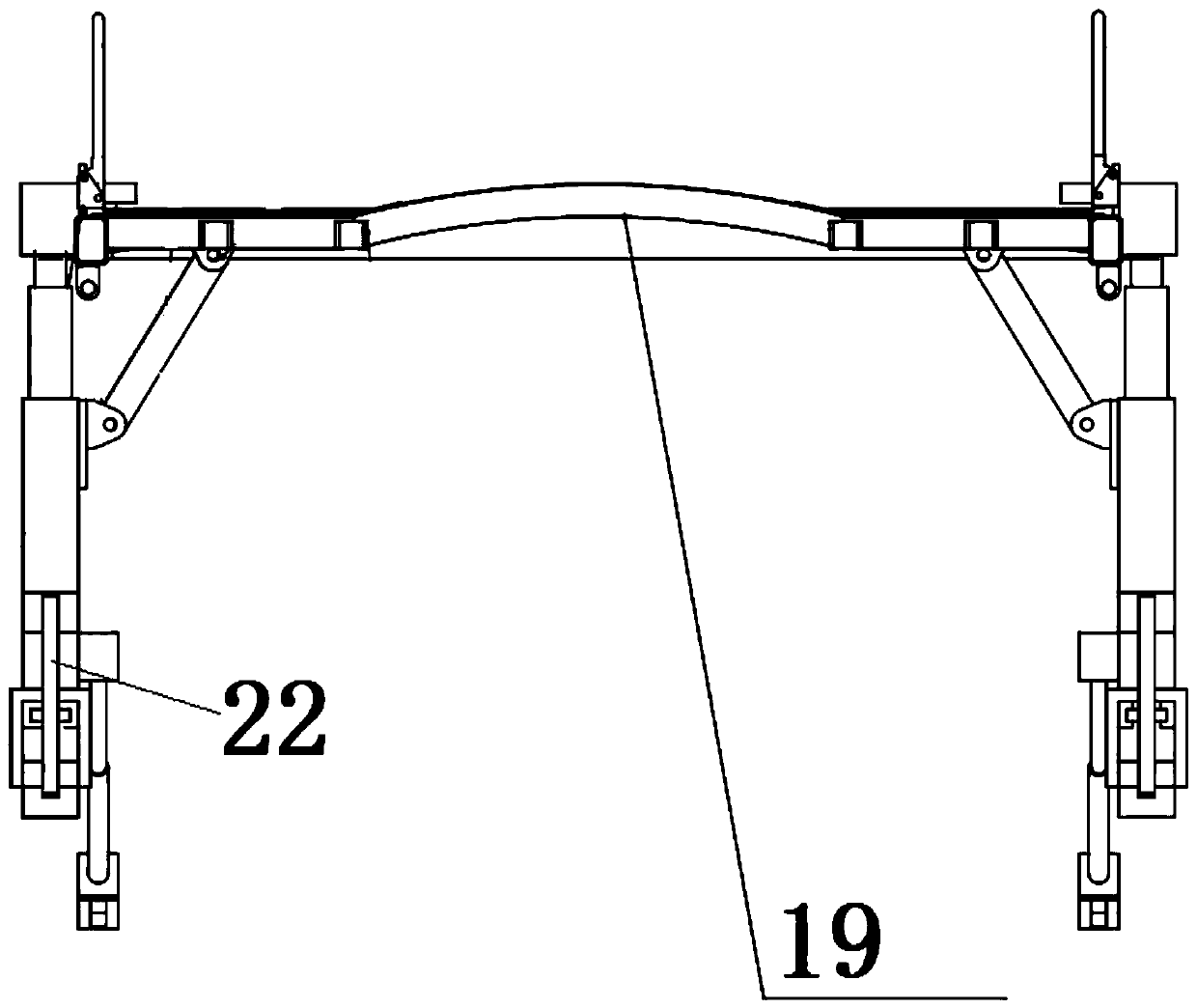

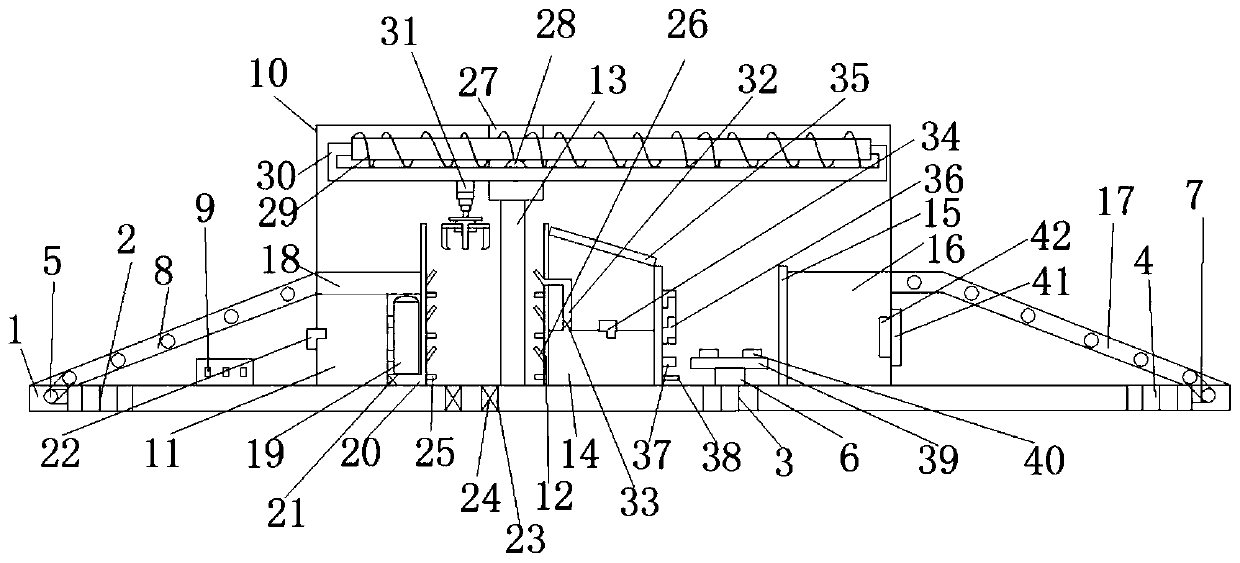

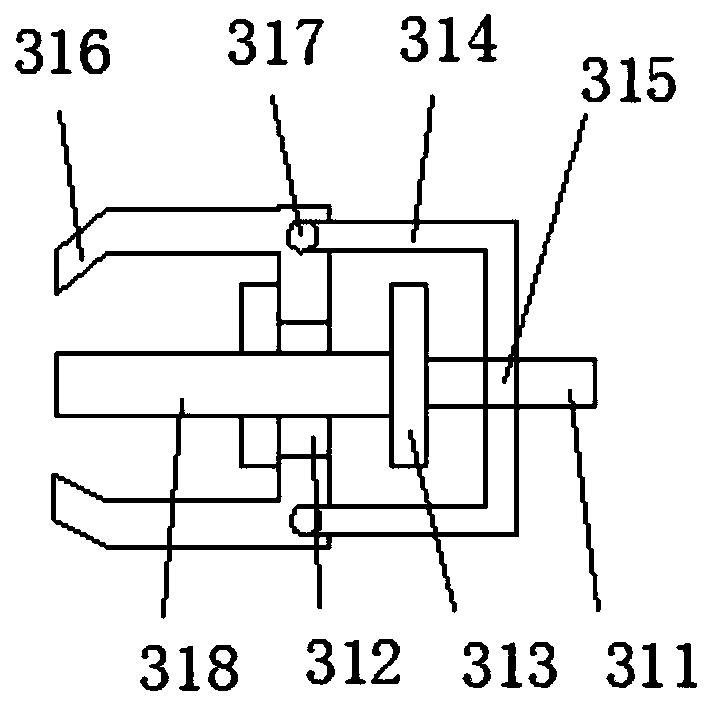

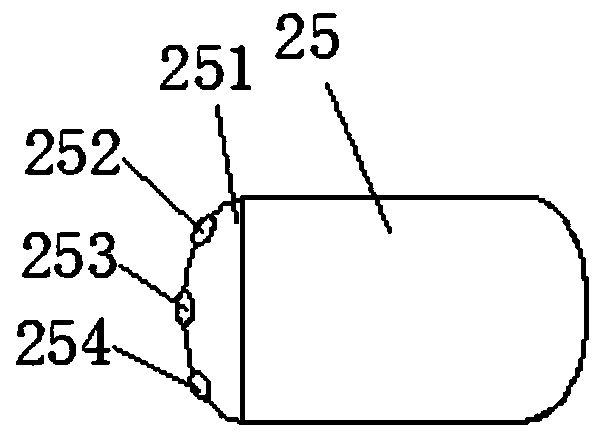

The invention discloses a gangway bridge device and relates to the technical field of marine equipment. The gangway bridge device comprises a base and a rotary platform which is installed above the base, wherein the rotary platform is connected with the base through a rotary mechanism, and a cab is arranged on the rotary platform. The gangway bridge device is characterized in that the rotary platform is connected with a gangway bridge, safety guardrails are arranged on the two sides of the gangway bridge, and a butt joint device is arranged at the suspended end of the gangway bridge. Compared with the prior art, the gangway bridge device has the advantages that the structural arrangement is reasonable, operation is stable, and staff can be transported between a ship and a marine platform in complicated and severe environments.

Owner:SOUTH CHINA MARINE MACHINERY

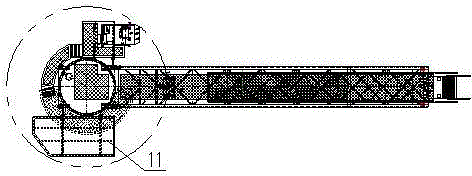

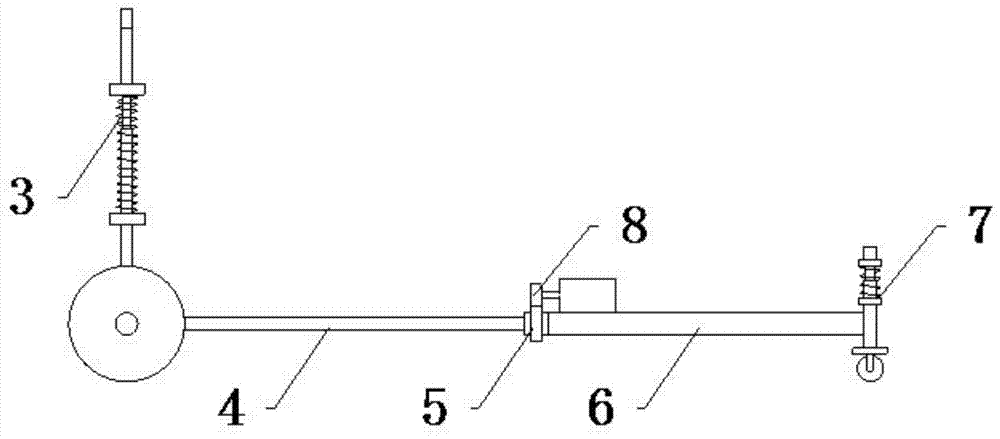

Posture control-based roller skating type mobility robot

ActiveCN105148496AEasy to controlEasy to operateSkate-boardsRoller skatesRoller skatingAttitude control

The invention discloses a posture control-based roller skating type mobility robot, which comprises a left roller skate body, a right roller skate body, a portable power supply, a communication controller and a posture detection system. The two roller skate bodies are of four-roller structures, and the left part and the right part are respectively provided with a driving roller, and the front part and the rear part are respectively provided with a small swivel castor, and the driving rollers are driven by a motor to rotate, so that the roller skate bodies can move in all directions. The 24V direct-current portable power supply provides electric drive for the roller skate bodies. The posture detection system obtains the upper body posture of an operator according to the relative spatial relation by six wireless motion capture sensors (WSSS (Wireless Standalone Sensing System)) so as to recognize the motion intention of the operator, and implements the motion intention by adjusting the rotational speed of the driving rollers of the roller skate bodies. The communication controller receives WSSS sensor information, generates a speed command with the assistance of a posture algorithm and transmits the speed command to a roller skate body controller, so that the driving rollers are controlled to rotate. The roller skating type mobility robot provides a tool integrated with mobility and entertainment functions for daily outings, and a novel set of control method is also provided for mobility vehicles.

Owner:HUAZHONG UNIV OF SCI & TECH

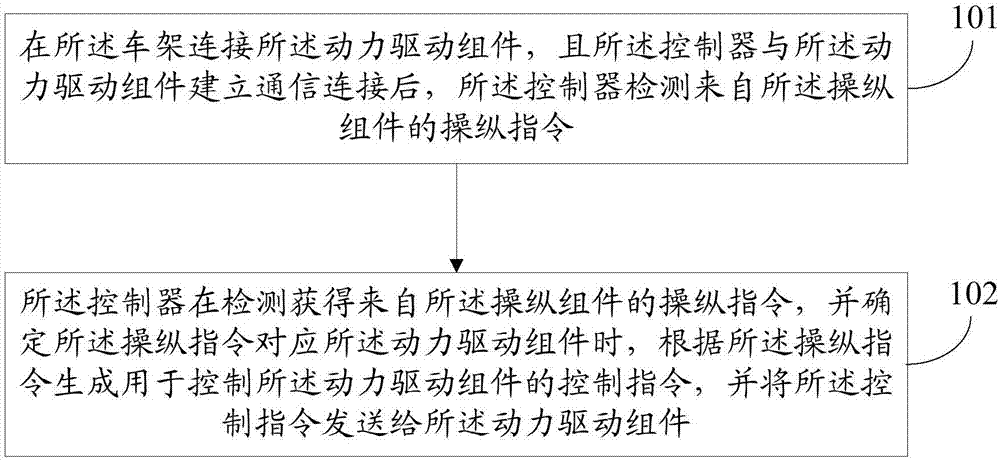

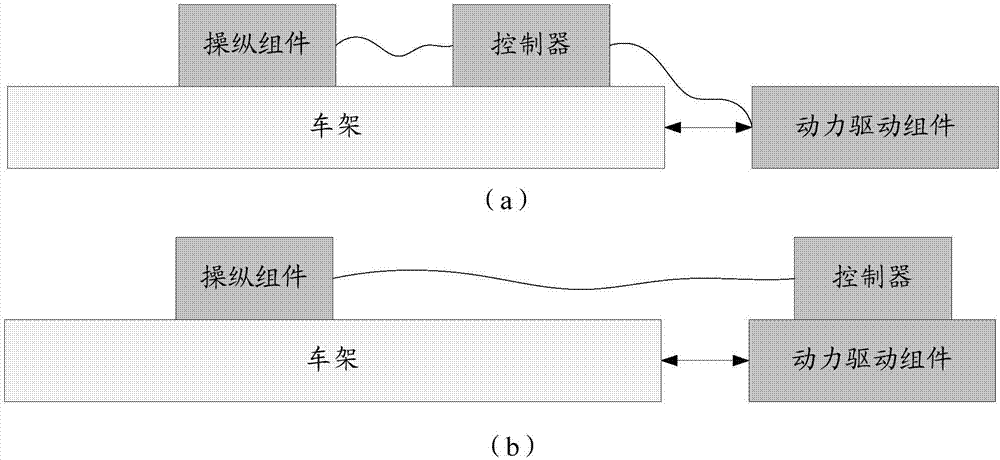

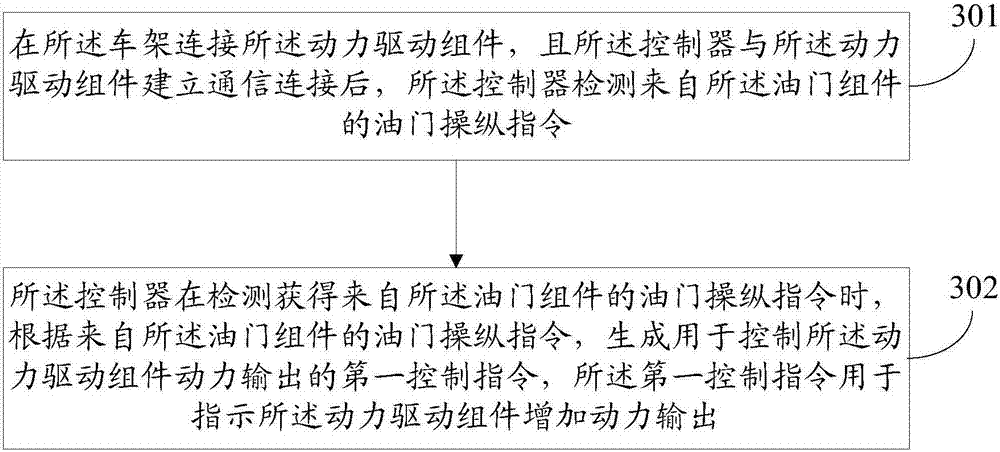

Control method, vehicle frame, power drive assembly and vehicle

ActiveCN107161260AReduce economic pressureHas racing featuresSpeed controllerMotorised scootersVehicle frame

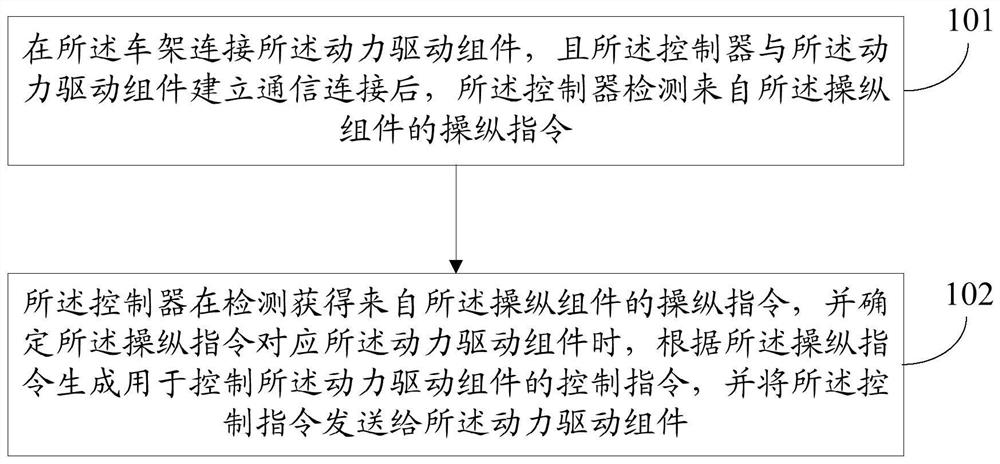

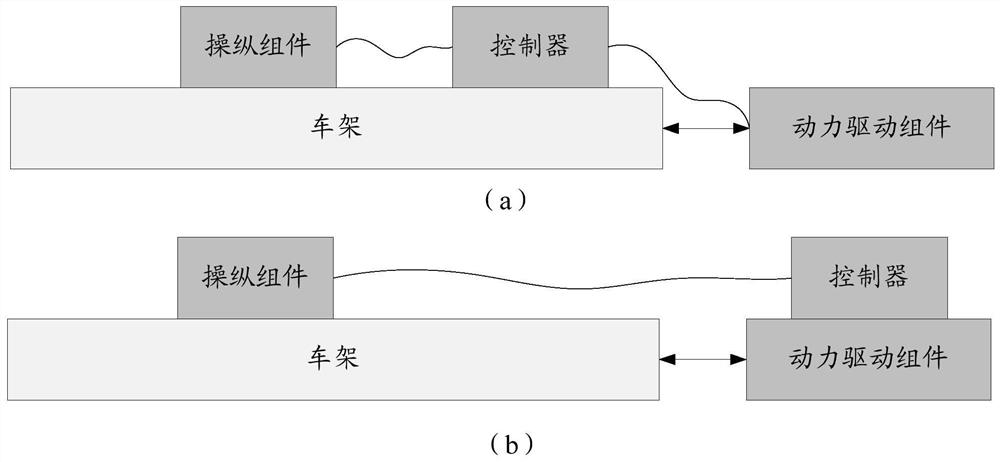

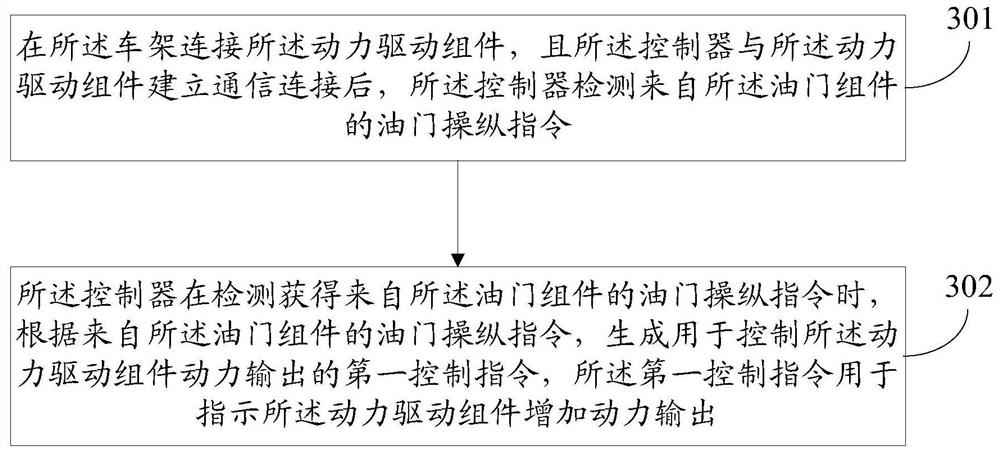

The invention discloses a control method, a vehicle frame, a power drive assembly and a vehicle. The vehicle frame is used for being connected with the power drive assembly and provided with a controller used for controlling the power drive assembly, and a manipulation assembly. The control method comprises the steps that after the power drive assembly is connected to the vehicle frame and the controller is in communication connection with the power drive assembly, the controller detects a manipulation instruction from the manipulation assembly; and when detecting and obtaining the manipulation instruction from the manipulation assembly and determining the fact that the manipulation instruction corresponds to the power drive assembly, the controller generates a control instruction used for controlling the power drive assembly according to the manipulation instruction and sends the control instruction to the power drive assembly.

Owner:NINEBOT (BEIJING) TECH CO LTD

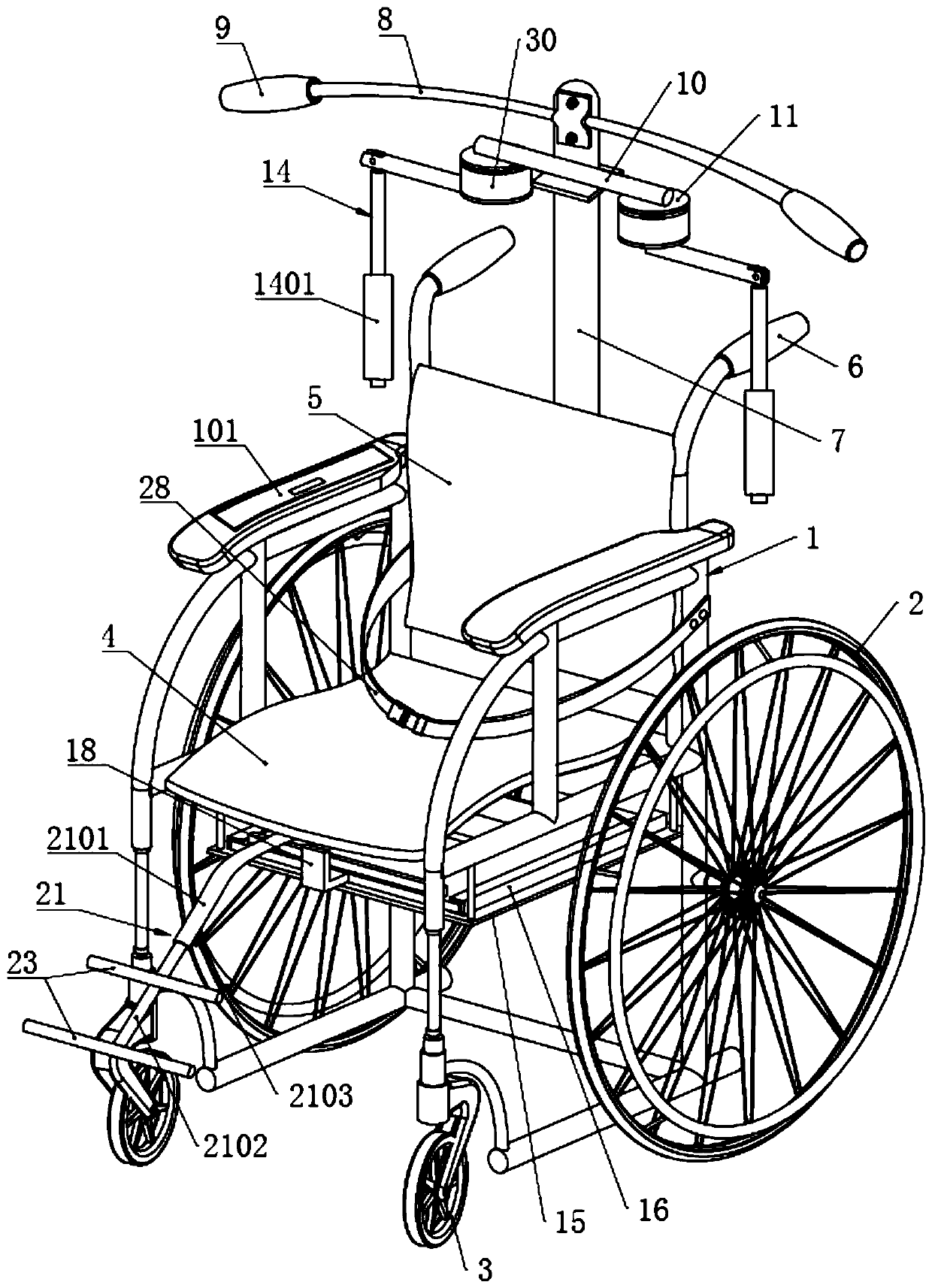

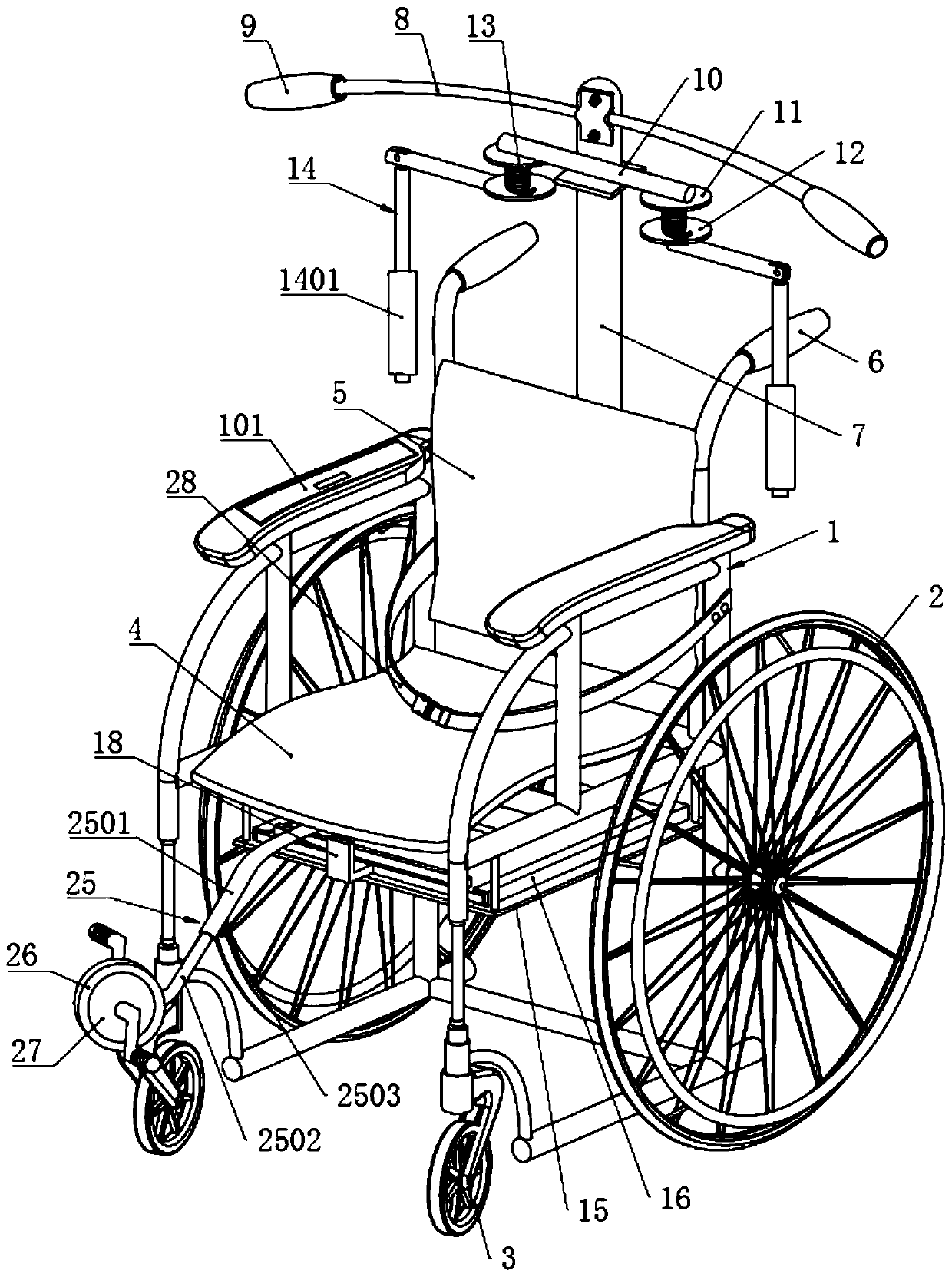

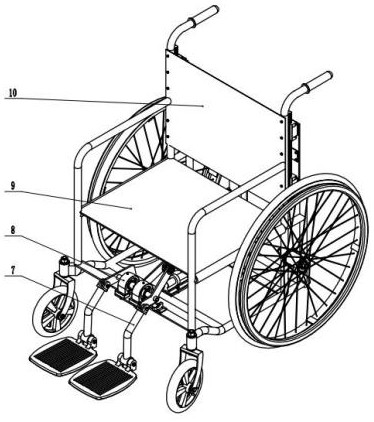

Multifunctional wheelchair with restoration function

InactiveCN109893352AAchieve exerciseSimple and convenient installation structureChiropractic devicesWheelchairs/patient conveyanceDrive wheelEngineering

The invention belongs to the technical field of medical equipment, and provides a multifunctional wheelchair with a restoration function. The multifunctional wheelchair comprises a wheelchair frame, wherein driving wheels, steering wheels, a cushion, a backrest and hand push armrests are mounted on the wheelchair frame; a vertical rod is fixedly mounted on the wheelchair frame and arranged againstthe backrest, an elastic rod is detachably mounted at the top end of the vertical rod, and handles are mounted at two ends of the elastic rod; a cross rod is further fixedly mounted on the vertical rod, fixed rotating discs are correspondingly mounted at two ends of the cross rod, movable rotating discs are rotationally mounted on the fixed rotating discs, torsion springs are arranged between themovable rotating discs and the fixed rotating discs in a sleeving manner, and arm rods are fixedly mounted on the movable rotating discs. The wheelchair has various functions, a user conveniently exercises muscles and joints from upper limbs to lower limbs on the wheelchair while the transportation function for the physically disabled and the mobility disabled is achieved. Degradation of body functions can be effectively avoided by rehabilitation exercise, and the rehabilitation effect is greatly improved.

Owner:潍坊复能肾病研究院

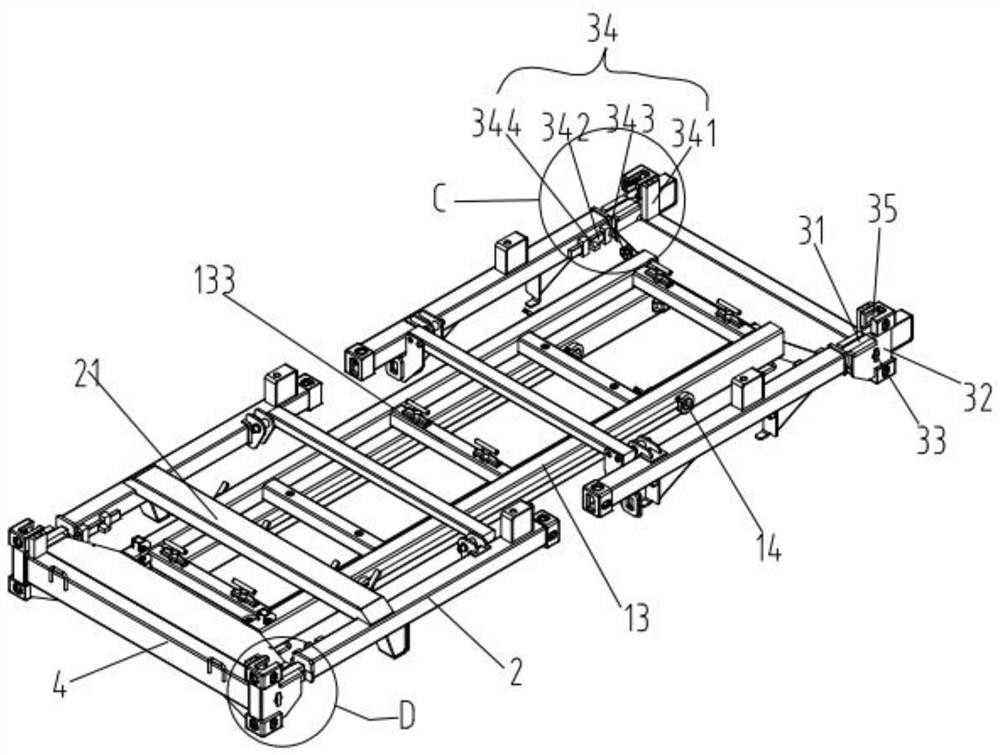

Automobile-container dual-purpose concave bottom transport vehicle

PendingCN111452811AAvoid collisionAdd transportation functionDraw-gearAxle-box lubricationTransportation technologyRail transportation

The invention discloses an automobile-container dual-purpose concave bottom transport vehicle, which belongs to the technical field of railway transportation, and comprises a lower layer underframe, amiddle underframe lifting device and an end underframe lifting device, the middle underframe lifting device comprises a middle upper layer underframe, a middle upper frame lifting device and a middleupper frame locking device; the middle upper frame lifting device is used for controlling a middle upper layer underframe to vertically lift; the middle upper frame locking device is used for lockingthe height of a middle upper layer underframe; the end underframe lifting device comprises an end upper-layer underframe and an end upper frame control device; the end upper frame control device is used for controlling lifting, locking and overturning of an end upper layer underframe. According to the automobile-container dual-purpose concave bottom transport vehicle, the full-length utilizationrate of the vehicle chassis can be effectively increased, the transport cost is reduced, container collision is avoided, the structure is exquisite, and operation is convenient.

Owner:CRRC MEISHAN

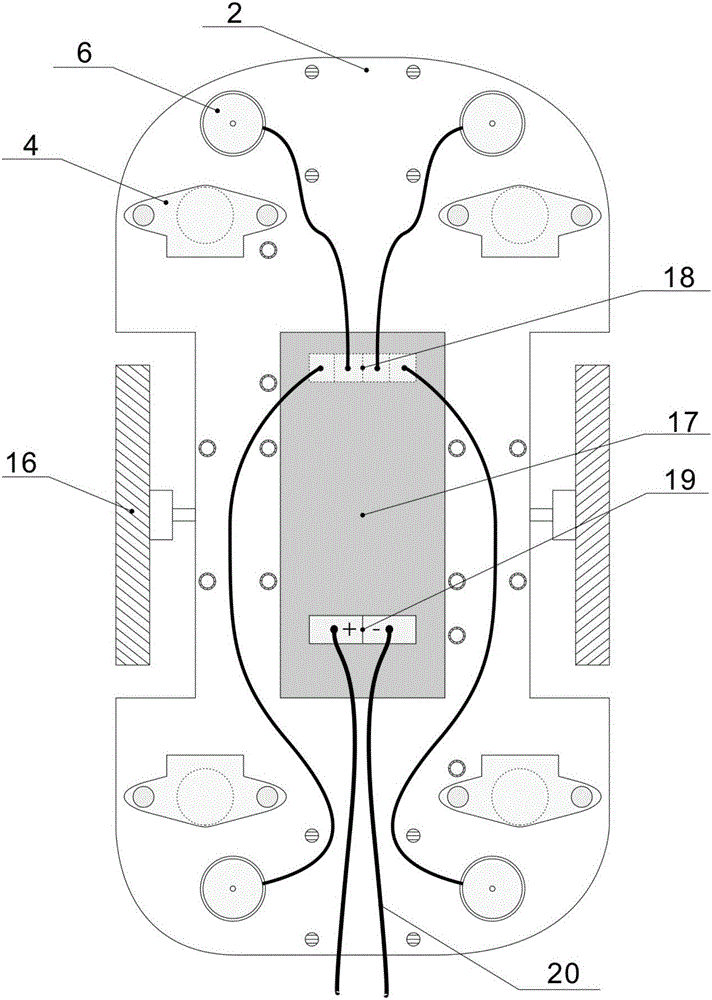

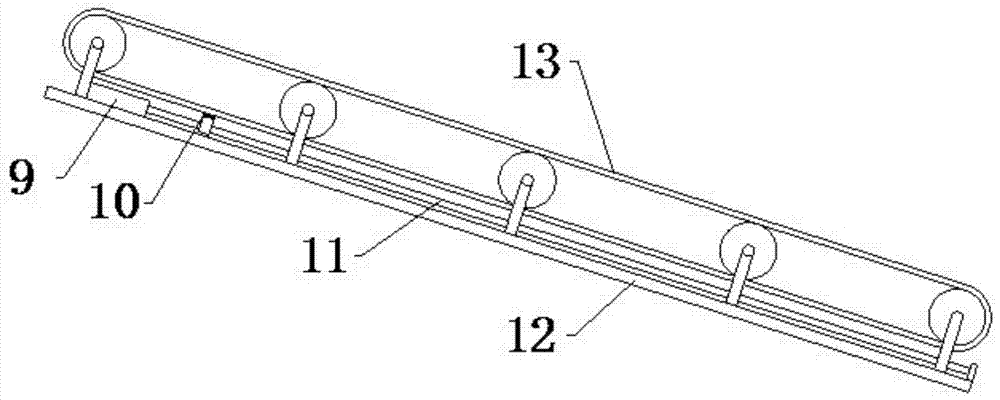

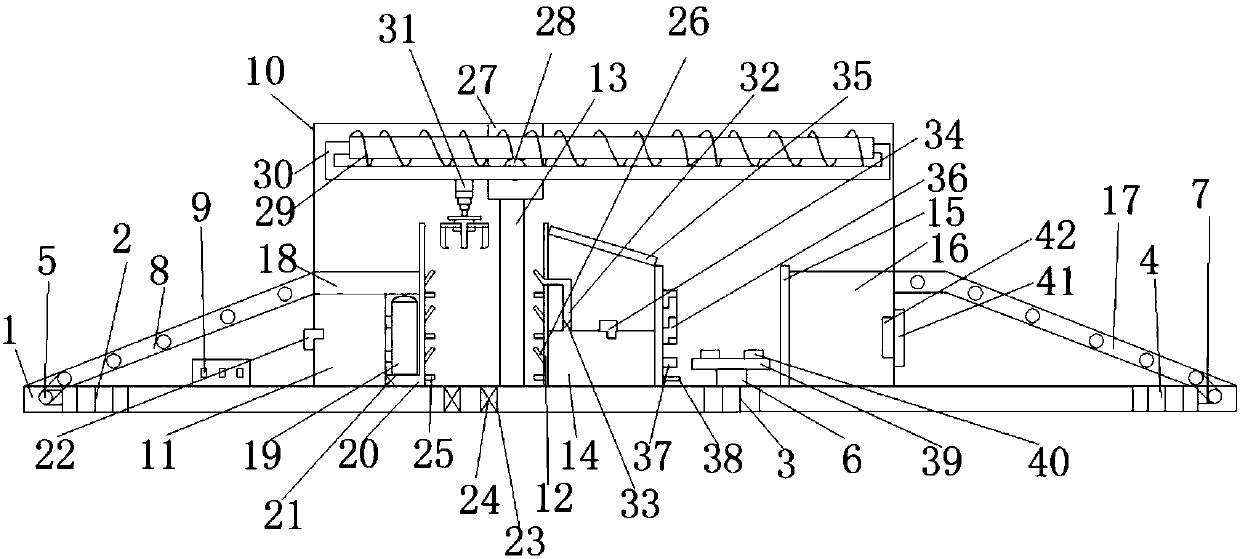

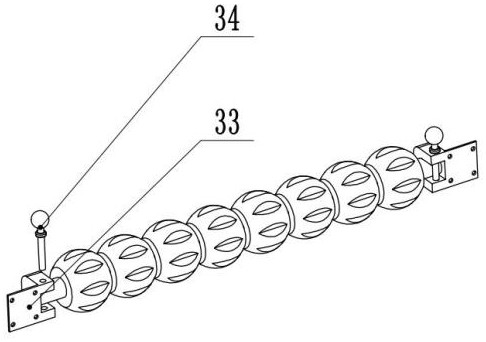

Screening device based on tobacco shred length control of thin cigarette

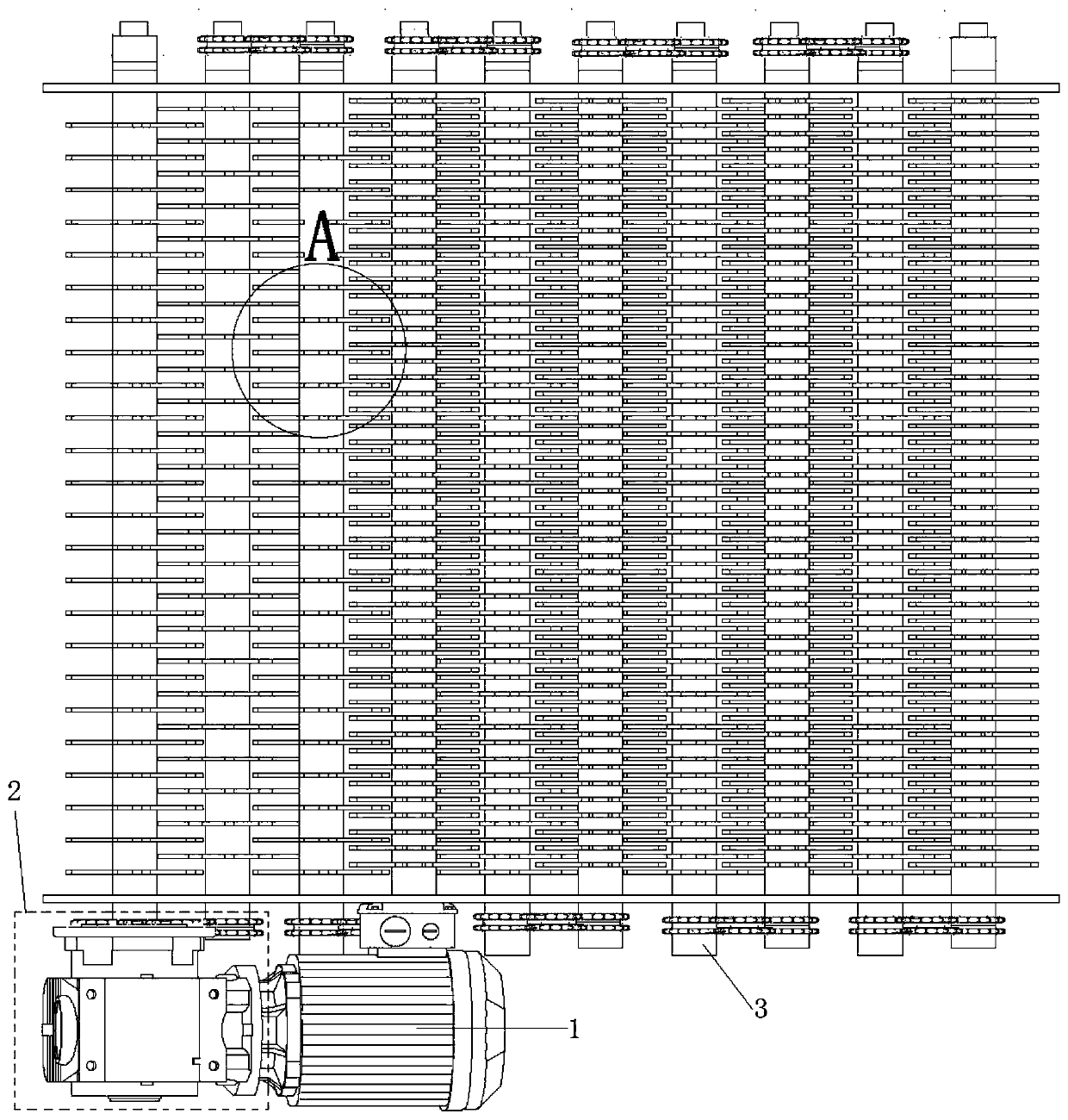

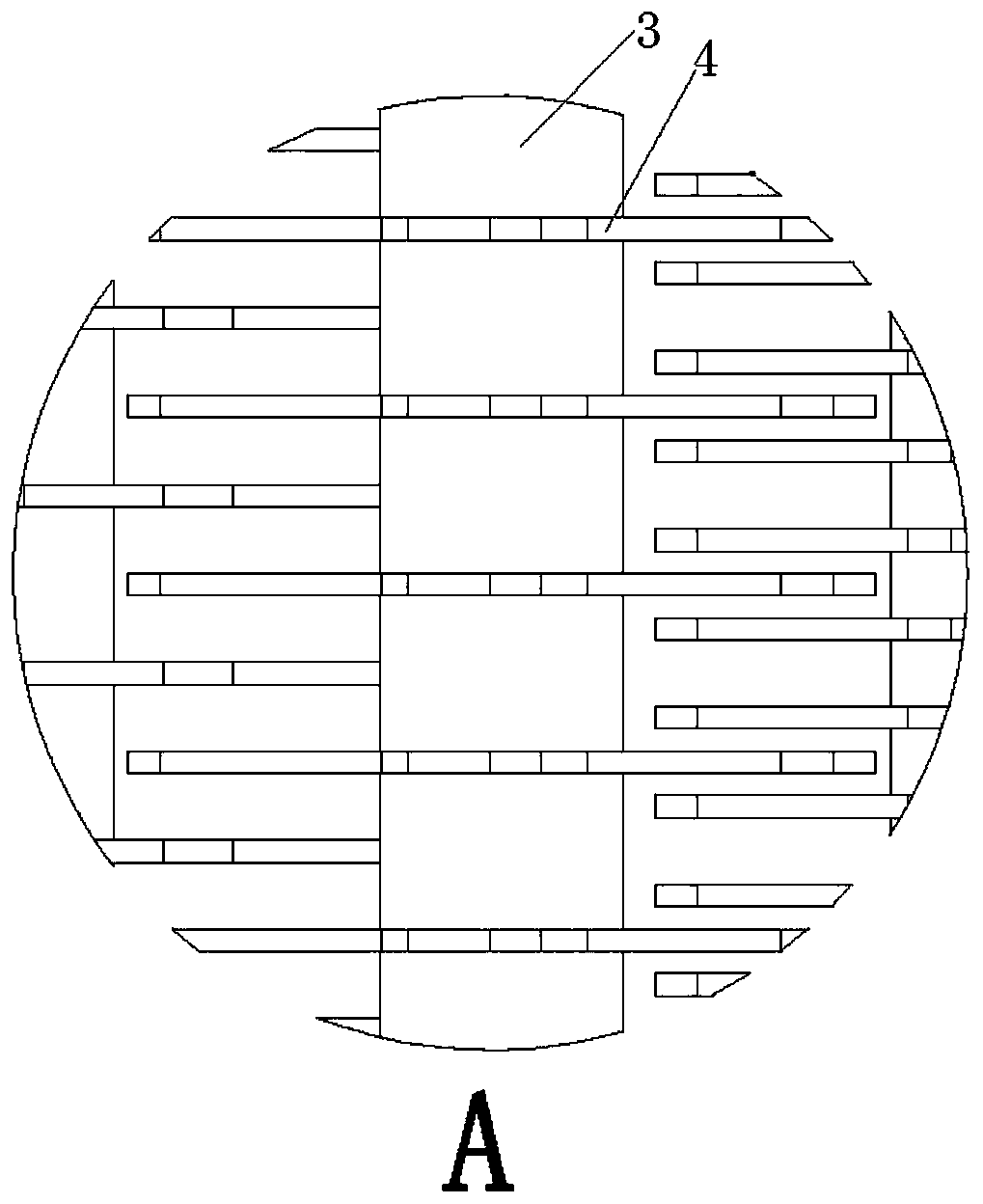

PendingCN110479610ARealize screeningRealize the transportation functionTobacco preparationGradingEngineeringMechanical engineering

The invention relates to a screening device based on tobacco shred length control of a thin cigarette. The screening device comprises a power source, a transmission mechanism and a plurality of movable rollers, wherein the plurality of movable rollers are driven by and rotates synchronously with the power source and the transmission mechanism and are arranged at equal intervals; picking tools arearranged on the movable rollers at equal intervals along the axial directions of the movable rollers; each picking tool comprises a plurality of blades for shifting tobacco shreds and a fixed disc fixed on the corresponding movable roller; the positions of the picking tools on the adjacent movable rollers are staggered; the blades of the picking tool on each movable roller extend to a gap formed by two adjacent blades of the adjacent movable rollers so as to form staggered structure with the blades on the adjacent movable rollers; and the two ends of the blades are spaced from the adjacent movable rollers at an equal interval. According to the screening device, the tobacco shreds are selectively screened in the conveying process, and the long tobacco shreds in the tobacco shreds are flexibly and selectively screened out to be prepared for cutting, so that the uniformity of a tobacco shred structure of the thin cigarette is improved, the applicability of the tobacco shreds of the thin cigarette is improved as well, and the comprehensive quality of rolling the thin cigarette is improved further.

Owner:CHINA TOBACCO JIANGSU INDAL +2

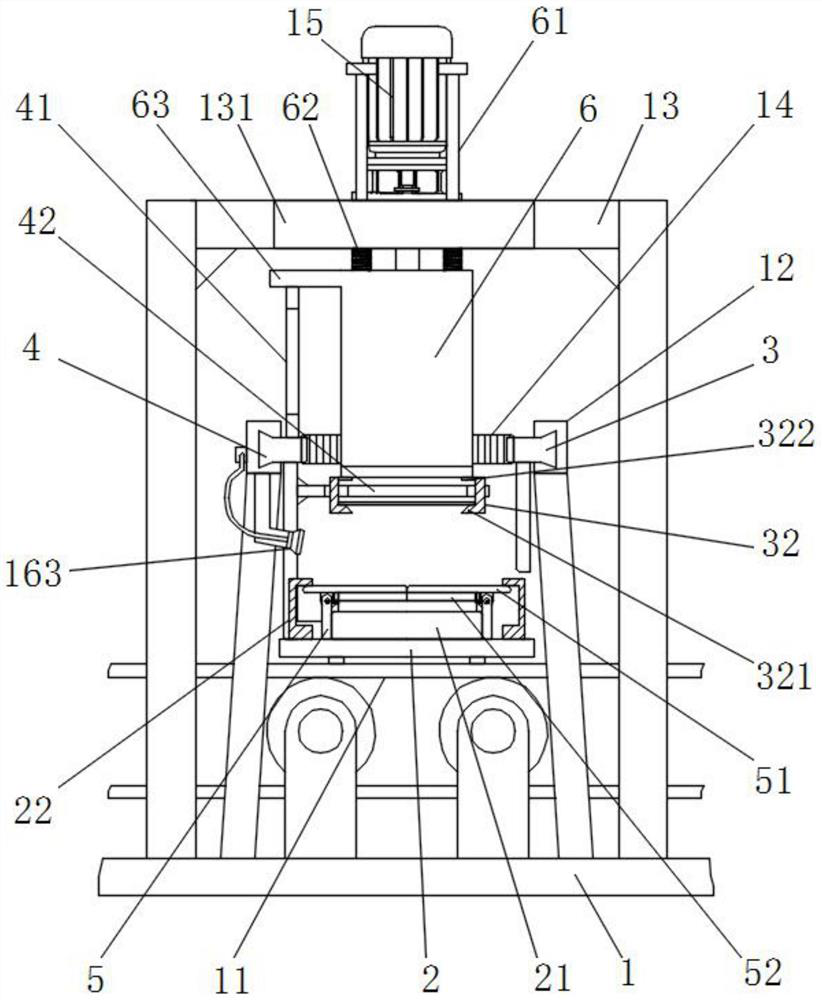

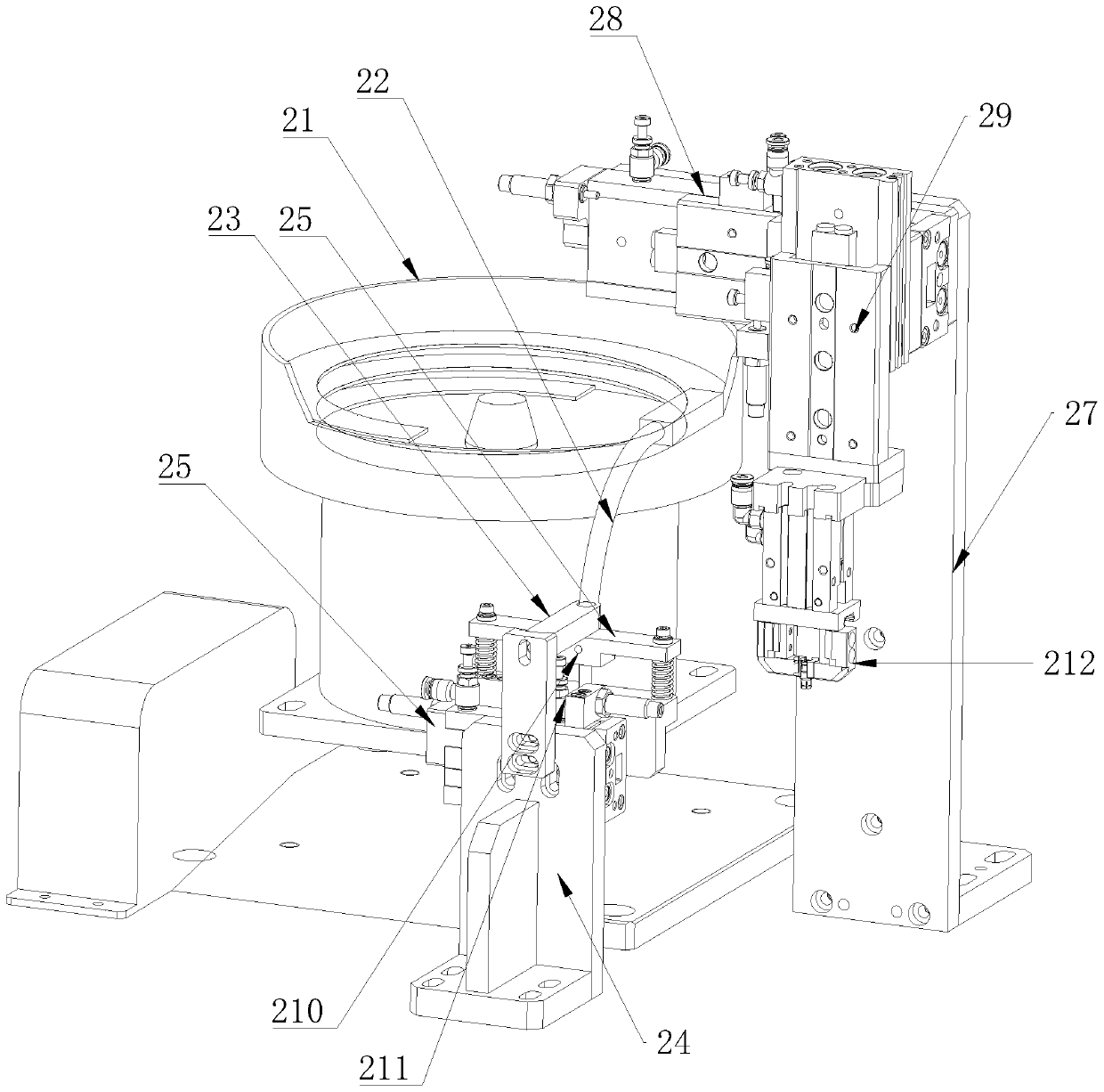

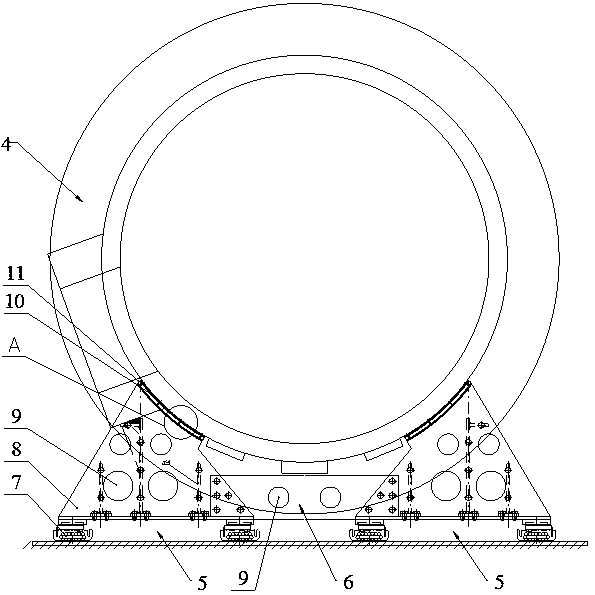

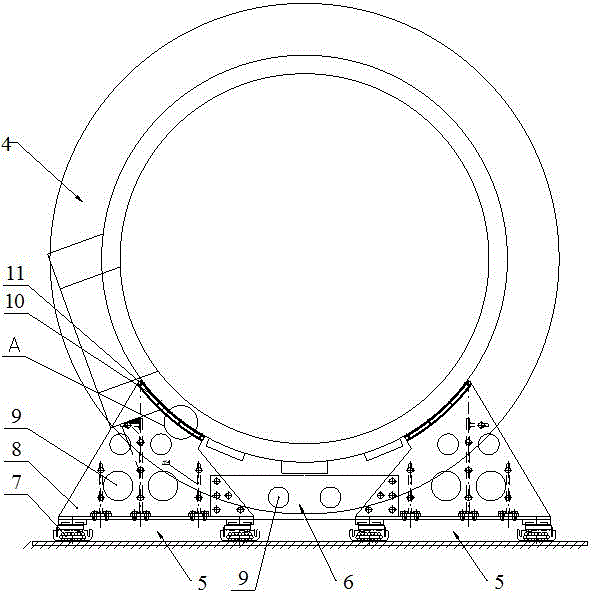

Plug tray placing machine

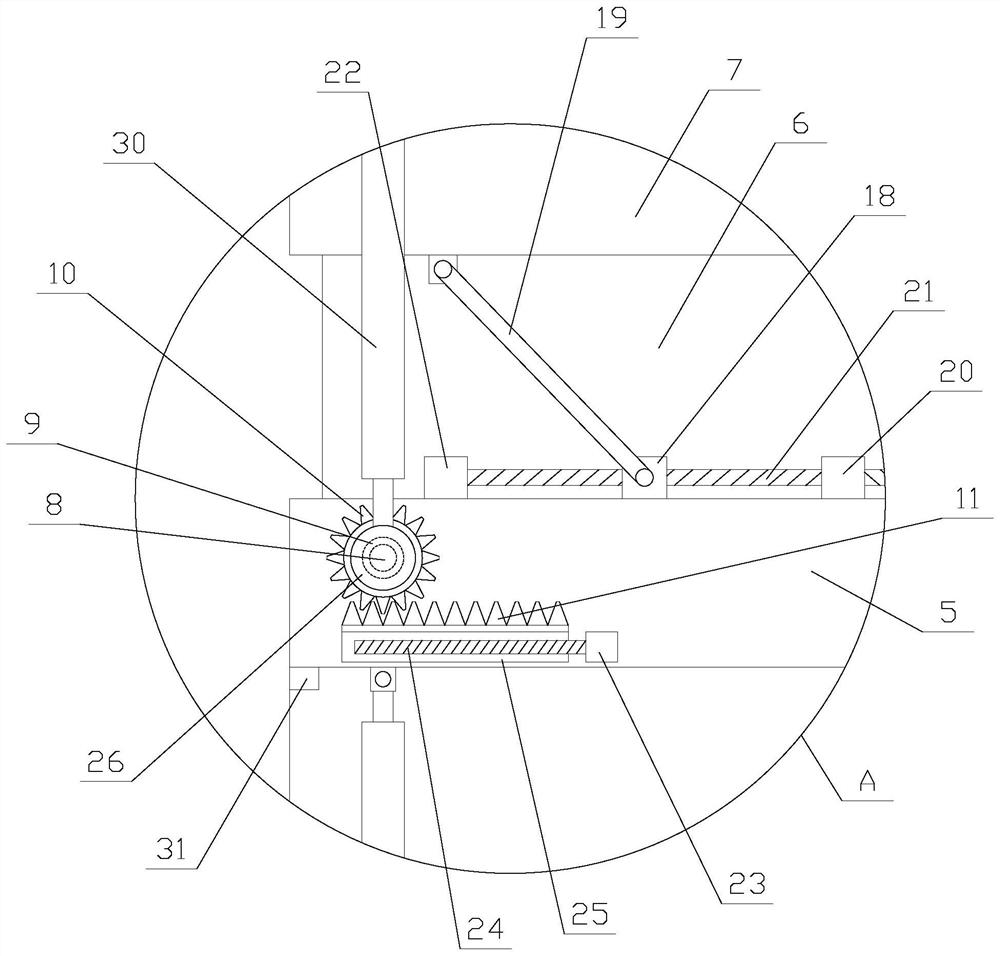

PendingCN108184394AAchieve protectionImprove protectionTransplantingEngineeringMechanical engineering

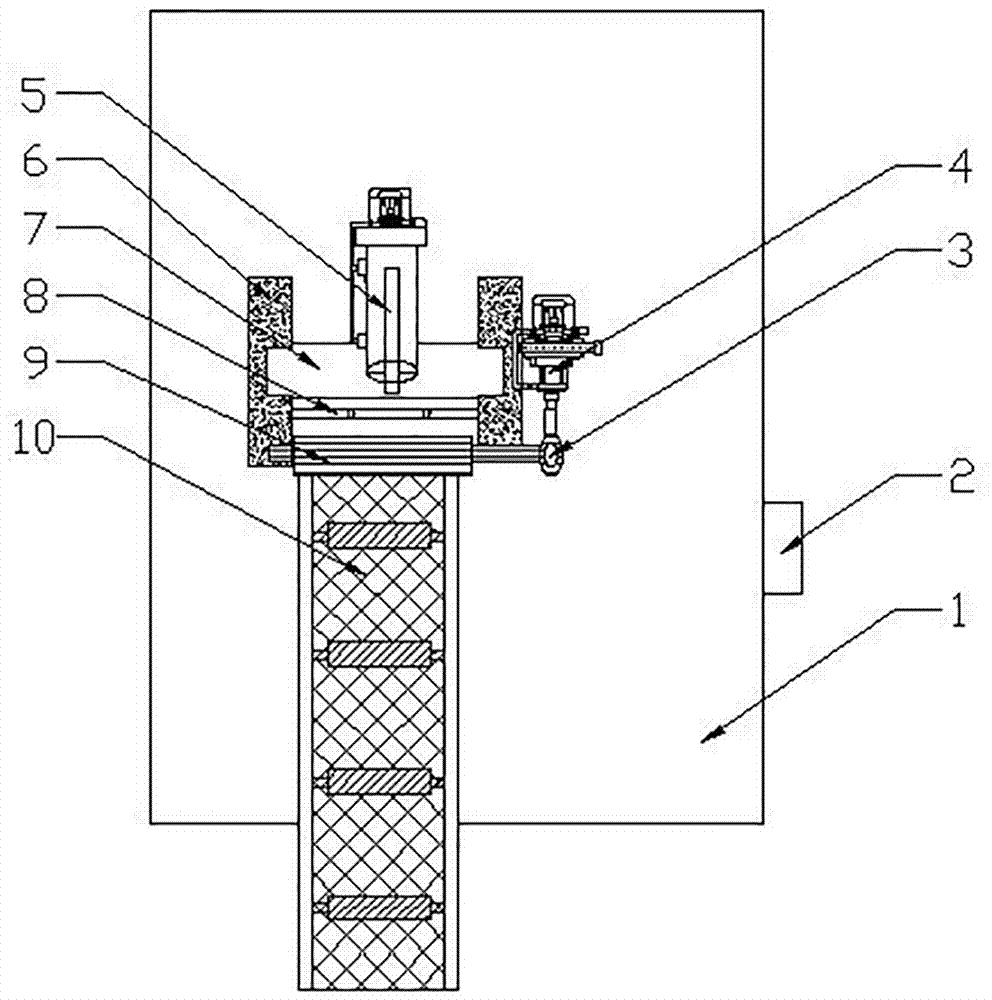

The invention discloses a plug tray placing machine. An ascending and descending support frame, a push rod support frame, a mechanical arm and walking wheels are arranged on a base; a support plate isarranged on the ascending and descending support frame; an inner ring of a rotary bearing is fixed on the support plate; a connecting arm is arranged on an outer ring of the rotary bearing; a carrying plate is arranged on the connecting arm; a plug tray bracket is arranged on the carrying plate; wheel teeth are reserved on an outer ring of the rotary bearing; the wheel teeth and a driving gear are engaged; the push rod support frame passes through the inner ring to be connected with a first electric push rod; a plug tray conveying belt is arranged on the mechanical arm. The plug tray placingmachine has the advantages that transportation and fast tray placing are integrated; during the plug tray placement, no damage is caused on seeds; the work efficiency is high; the manual burden is reduced; the cost can also be effectively reduced.

Owner:HEBEI AGRICULTURAL UNIV.

Paralyzed patient rehabilitation walking device

InactiveCN112914859AAids in rehabilitation exercisesEven by forcePneumatic massageChiropractic devicesPhysical medicine and rehabilitationElectric machinery

The invention discloses a paralyzed patient rehabilitation walking device. The paralyzed patient rehabilitation walking device comprises a rack; an auxiliary frame is fixedly connected to the middle of the top of the rack; a sliding rail is fixedly connected to the back of the top of the rack; a lifter is arranged in an inner cavity of the sliding rail; a folding seat is fixedly connected to the top of a pedestal pan; a double-shaft air cylinder is arranged at the top of a connecting rod between the air pressure columns; a gear motor is arranged at the top of the double-shaft air cylinder; a second telescopic air cylinder is arranged at the bottom of the double-shaft air cylinder; a supporting arm is fixedly connected to one end of the bottom of the second telescopic air cylinder; a chest protector is arranged on the back of the top of the machine panel; a chest air bag is arranged on one side, facing the folding seat, of the chest protector; a third telescopic air cylinder is arranged in an inner cavity of an extension rod on the back face of the machine panel; a backrest is arranged on the back of the top of the third telescopic air cylinder; an air bag is arranged on the front face of the backrest; armrests are arranged on the back of the backrest; and a crossing belt is arranged on the back of the bottom of the machine table panel.

Owner:吉世斌

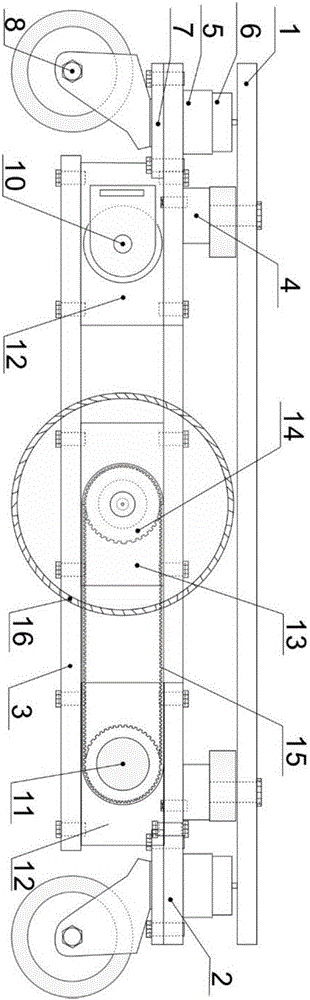

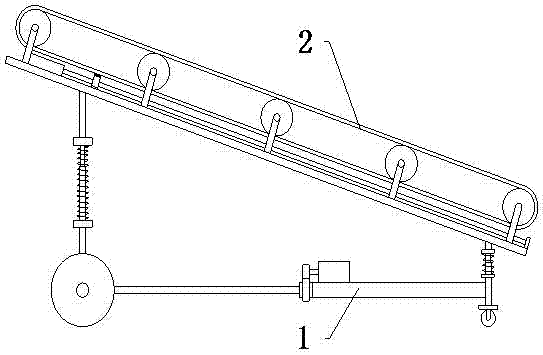

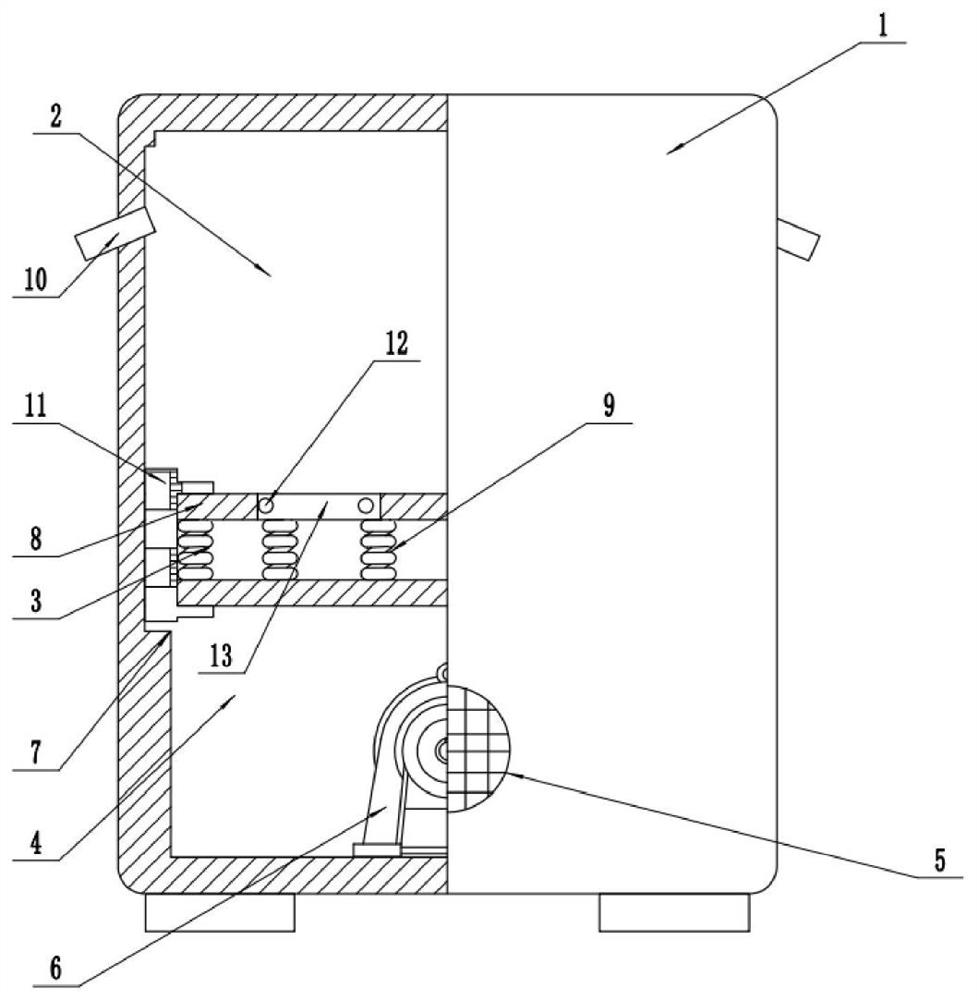

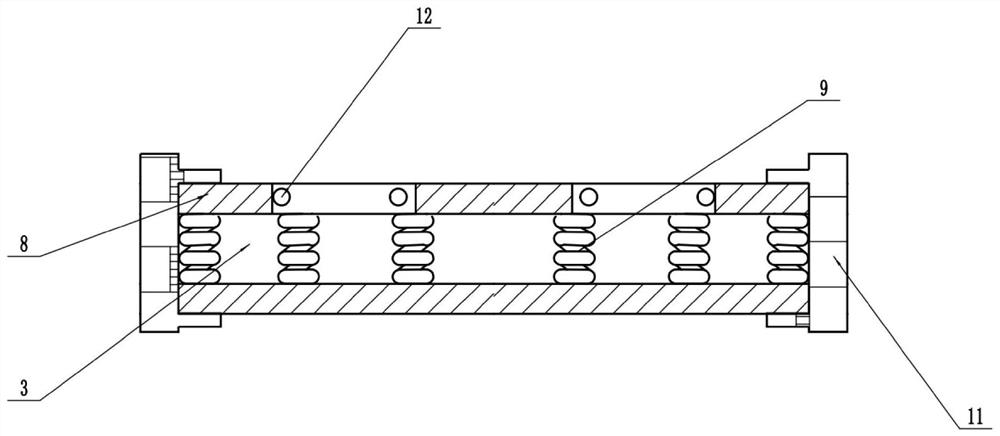

Shockproof belt type conveyor capable of lifting

PendingCN107499857ARealize the shock absorption functionImplement mobile functionalityCleaningPackagingEngineeringBelt conveyor

The invention provides a shockproof belt type conveyor capable of lifting. The conveyor comprises first shock absorbers, a first screw rod, an annular gear, a hollow rod, second shock absorbers, a transmission gear, a servo motor, a scraper, a second screw rod and an installation plate; the first screw rod is arranged on the right ends of the first shock absorbers, the hollow rod is arranged on the right end of the first screw rod, the second shock absorbers are arranged on the right end of the hollow rod, the annular gear is arranged on the first screw rod, the transmission gear is arranged on the upper end of the annular gear, and according to the deign, both the shockproof function and the lifting function can be realized; and the servo motor is arranged on the upper end of the installation plate, the second screw rod is arranged on the right end of the servo motor, the second screw rod is provided with the scraper, and according to the design, conveyor belts on the belt type convey can be cleaned. According to the belt type conveyor, the use is convenient, the application range is enlarged, the service life is prolonged, and the reliability is high.

Owner:洛阳益矿机械设备有限公司

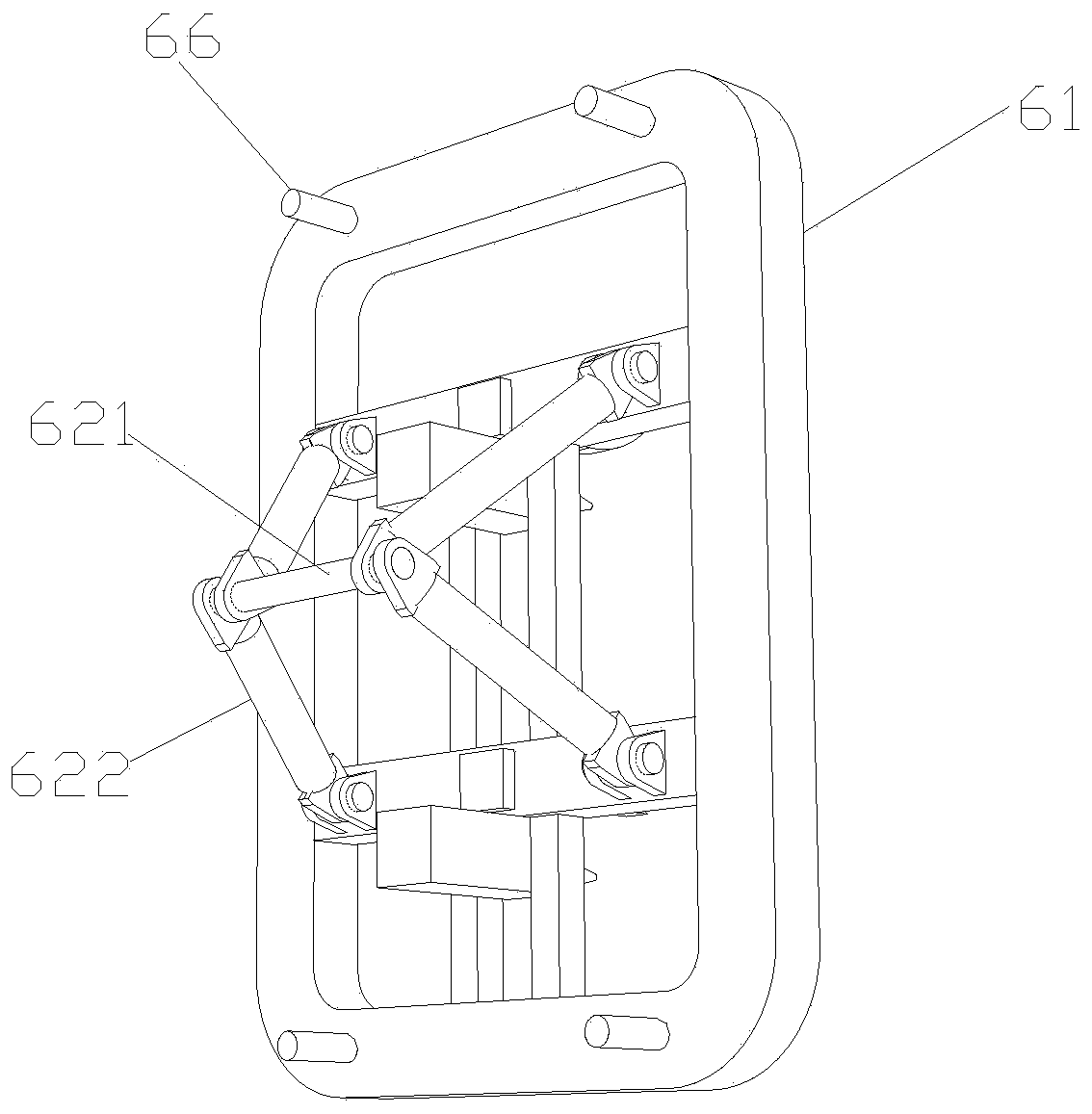

Mobile phone film pasting device

InactiveCN112706982ARealize the wipe functionRealize the transportation functionPackagingEngineeringConveyor belt

The invention discloses a mobile phone film pasting device which comprises a base, wherein a conveyor belt assembly is arranged at the top of the base, a conveying plate is arranged outside the conveyor belt assembly, a mobile phone clamping base is fixedly connected to the top of the conveying plate, two sets of sliding supports are arranged at the top of the conveyor belt assembly, two ends of the two sets of sliding supports are fixedly connected with the base through mounting frames, a first rack and a second rack are respectively and slidably mounted at the inner sides of the two sets of sliding supports, and a top plate is arranged at the tops of the sliding supports and fixedly mounted at the top of the base through the mounting frames. According to the device, by controlling the first rack and the second rack to move in opposite directions, the wiping function on a mobile phone screen is achieved, a cleaning pressing block is used for achieving the function of scraping the surface of a film outwards, the film body is tightly attached to the mobile phone, then the film pasting operation is completed, and the film pasting efficiency of the protective film before the delivery of the mobile phone is improved.

Owner:刘亚亚

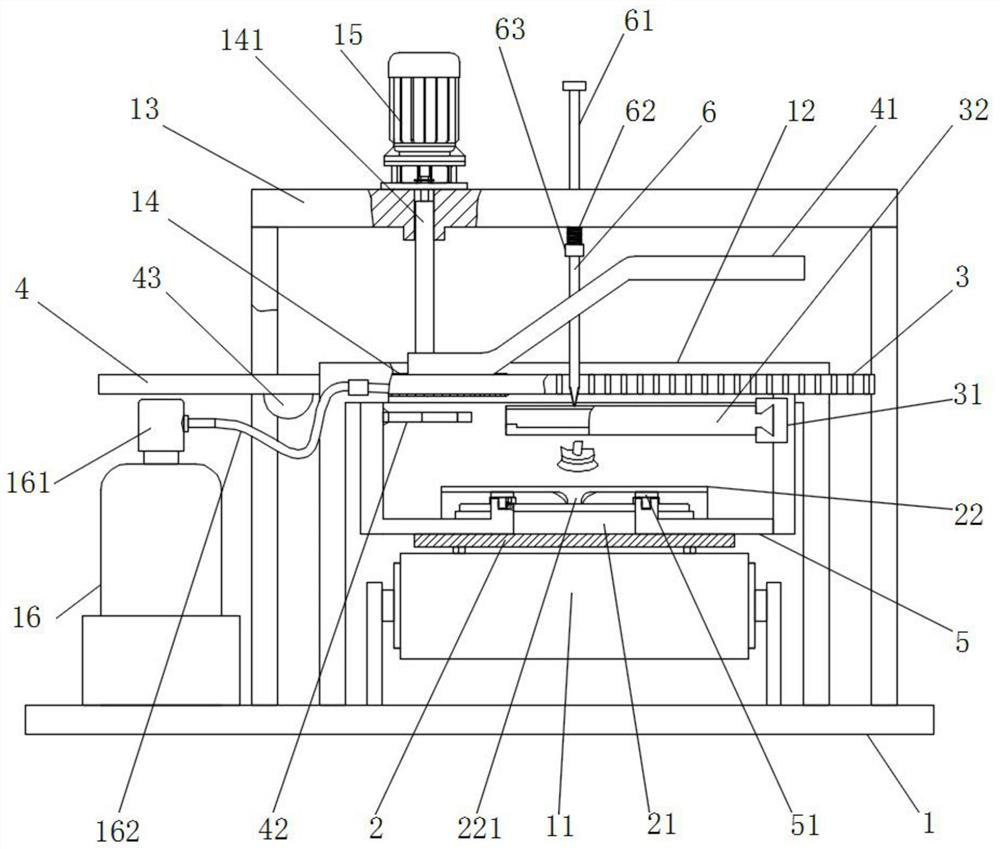

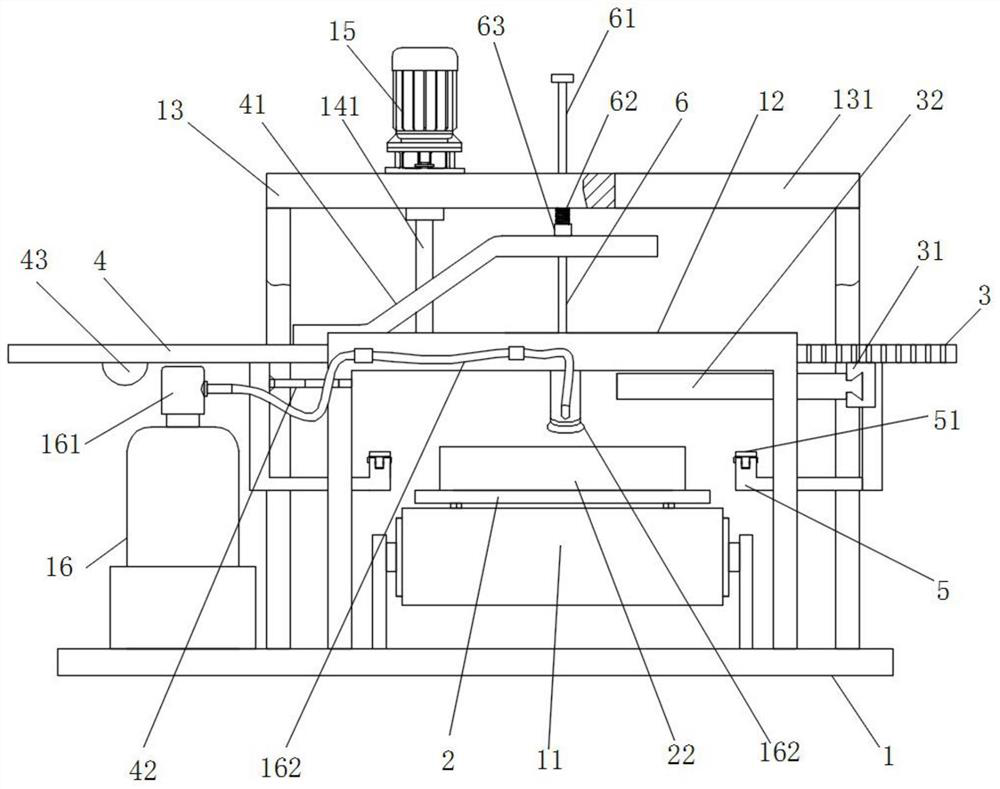

Electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings

ActiveCN107904648AImprove work efficiencyAchieve tidinessElectrophoretic coatingsElectric machineryWater pipe

The invention discloses an electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings. The electrophoresis paint-spraying pretreatment device comprises a housingI, wherein an inner cavity of the housing I is hollow; the bottom wall of the housing I is sequentially connected with a motor I, a motor II and a motor III in the horizontal direction; one end of themotor I, one end of the motor II and one end of the motor III are separately connected with a rotary shaft I, a rotary shaft II and a rotary shaft III; the top of the housing I is sequentially connected with a conveyor belt I, a controller, a frame body, a water tank, a barrel body, a supporting rod, a booster pump, a housing II, an electrophoresis slot and a conveyor belt II in the horizontal direction; one end, away from the housing I, of the conveyor belt I is fixedly connected with a placing plate; the placing plate is positioned on the top of the water tank; and the side wall of one side, away from the conveyor belt, of the water tank is sequentially connected with a water pump and a water introducing tube in the vertical direction. The electrophoresis paint-spraying pretreatment device is simple in structure, is convenient to operate, realizes pretreatment for electrophoresis parts and fittings and a treatment function after electrophoresis is completed, and improves electrophoresis quality.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

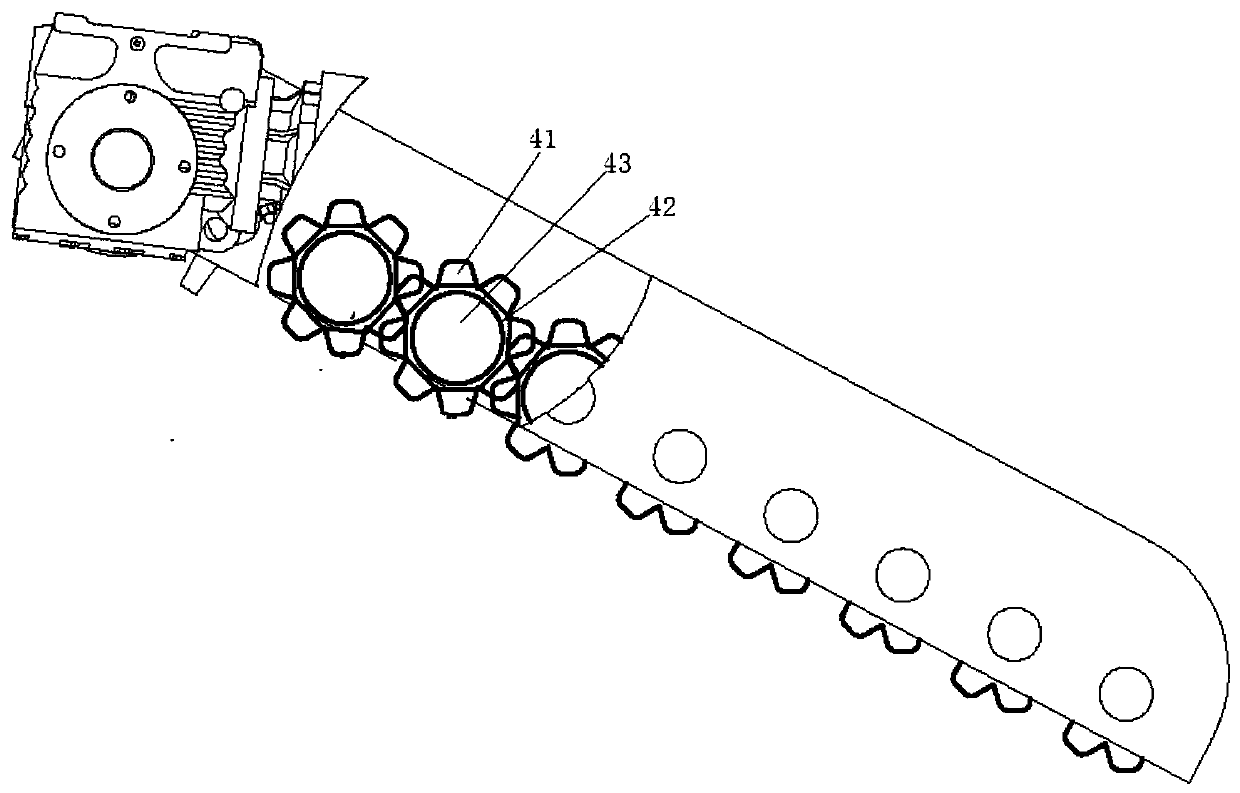

Automatic rubber shearing device

PendingCN107443443AEasy to operateImplement the placement functionMetal working apparatusRubber materialStructural engineering

The invention discloses an automatic rubber shearing device. The automatic rubber shearing device comprises a workbench, a feeder, tool rests and a runway, wherein one side of the workbench is equipped with a pedal switch; the runway is arranged on the workbench; one end of the runway is equipped with an entering and shrinking rolling rod; the two ends of the entering and shrinking rolling rod are perpendicularly equipped with the tool rests; one side of the tool rest is equipped with the feeder; the feeder is in shaft connection with one end of the entering and shrinking rolling rod; one side of the feeder is equipped with a feeding air cylinder; and notches are formed inside the two tool rests. According to the automatic rubber shearing device disclosed by the invention, the pedal switch is arranged, so that a worker operates circuit to open and close in a pedaling mode, and therefore, operation of the worker is convenient; the feeder comprises a one-way bearing feeder and a computer-driven feeder, and realizes an automatic feeding function; a tool rest air cylinder is matched with a cutter, so that the rubber shearing function is realized; an edge-fixing air cylinder steel plate is arranged, so that a placing function for to-be-sheared rubber materials is realized; the runway is arranged, so that the transportation function of the sheared rubber materials is realized, and therefore, next-step utilization is performed; and the automatic rubber shearing device is reasonable in design, and is suitable for being popularized and used.

Owner:刘远堂

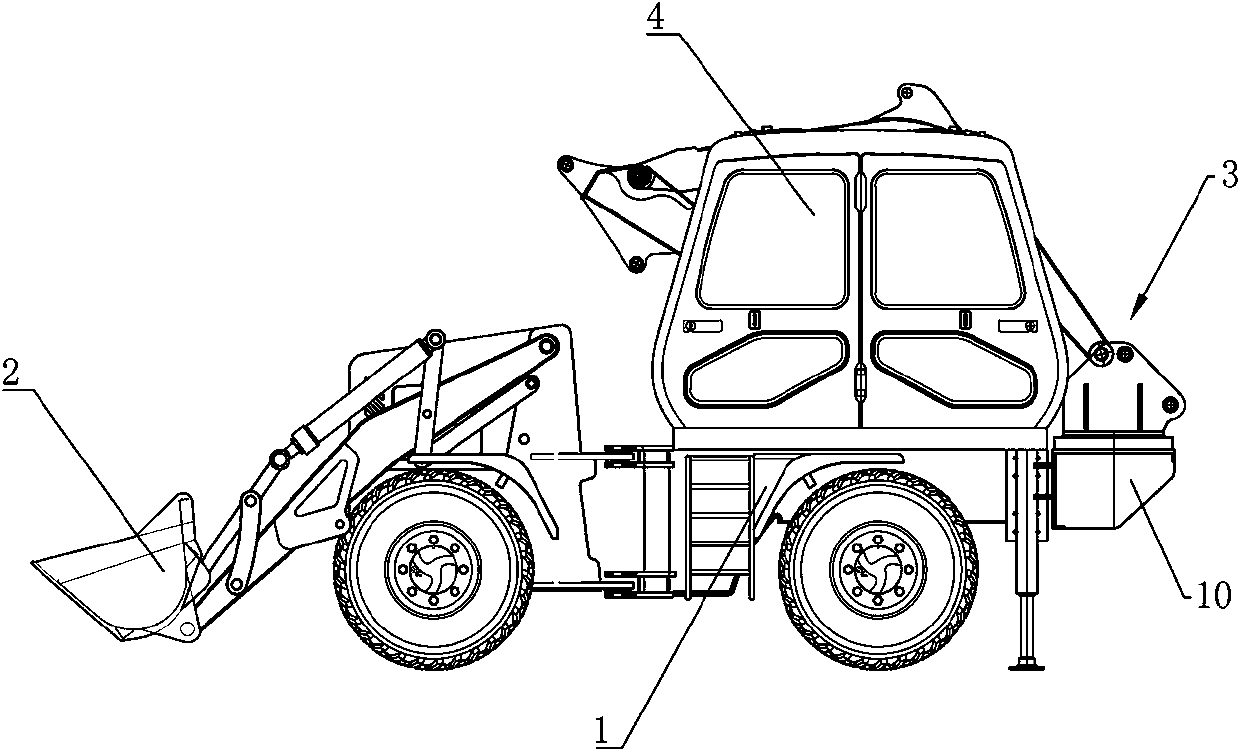

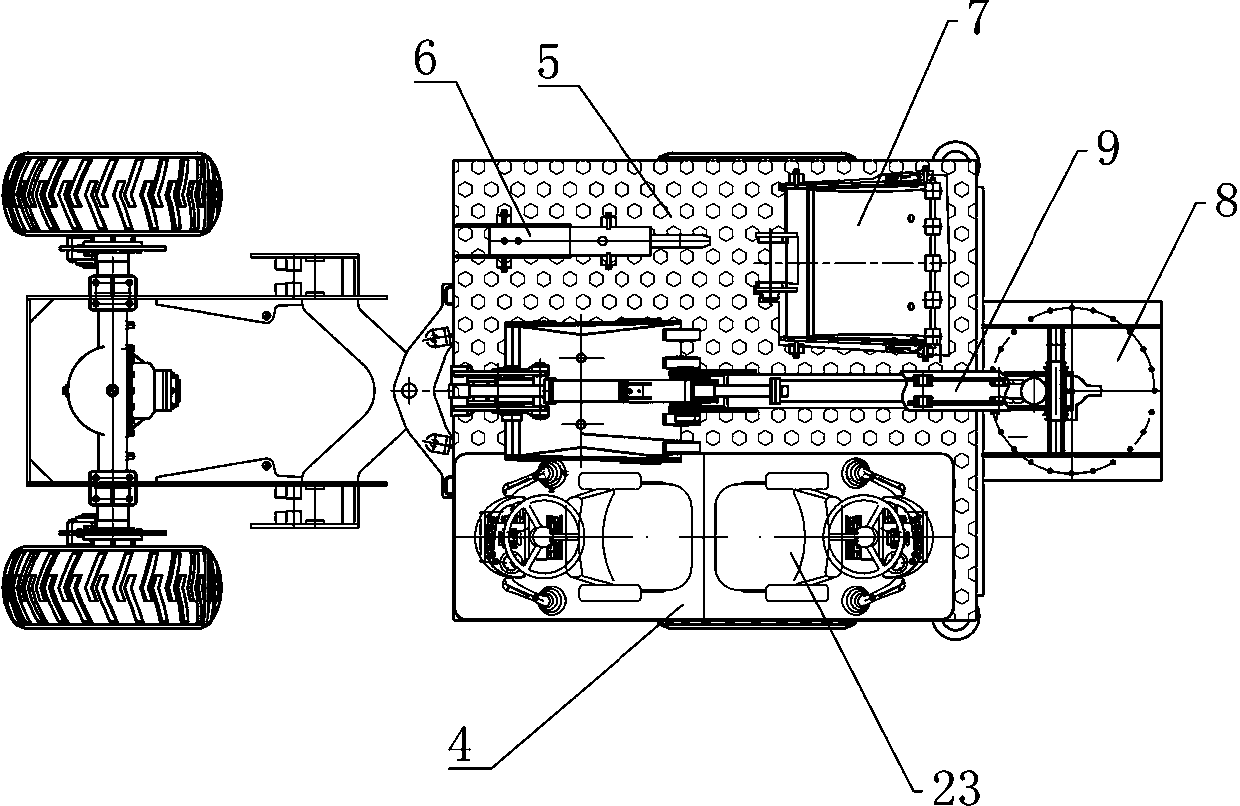

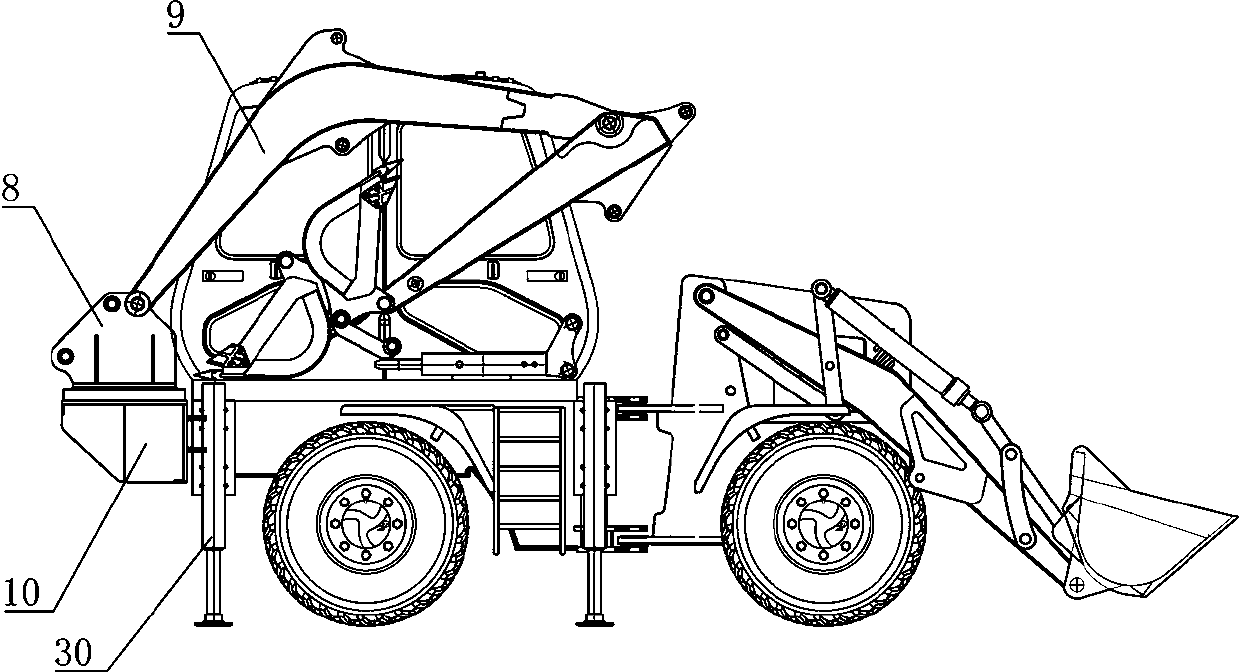

Novel backhoe loader

PendingCN110397103ASolve functionSolve efficiency problemsMechanical machines/dredgersState of artEngineering

The invention provides a novel backhoe loader. The novel backhoe loader solves the problem that in the prior art, an engineering machine only has a single function and is low in construction efficiency. The novel backhoe loader comprises a movable vehicle body. A loading portion is arranged at one end of the vehicle body, and an excavation portion is arranged at the other end of the vehicle body.A cab is further arranged on the vehicle body and located between the loading portion and the excavation portion. The loading portion is located on the center line in the front-back direction of the vehicle body. The cab is located on one side of the center line. One side of the cab is further provided with a standby platform used for storing accessories. The excavation portion comprises a first rotating base and an excavation big arm installed on the first rotating base. The first rotating base drives the excavation big arm to rotate by 360 degrees in the horizontal plane. When the excavationbig arm rotates to be in the same direction with the front-back direction of the vehicle body, the excavation big arm is located on one side of the cab, and the tail end of the excavation big arm islocated on the standby platform. The novel backhoe loader is simple in structure and convenient to use, has multiple functions, can cooperate to complete multiple different operations, greatly improves the construction efficiency and has good practicability.

Owner:莱州巨浪机械有限公司

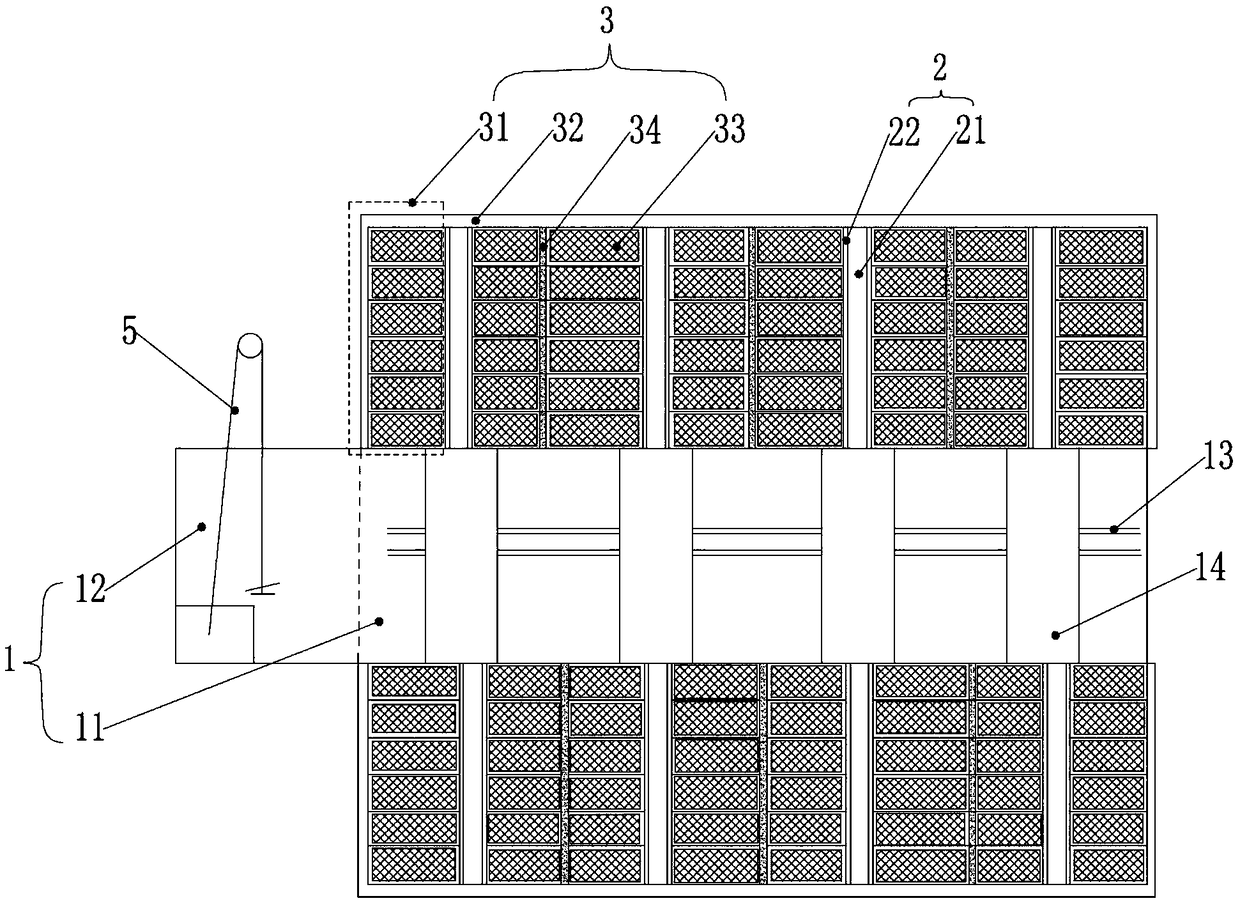

Multifunctional aquaculture platform

InactiveCN109006585AReduce difficultyImprove work efficiencyClimate change adaptationPisciculture and aquariaAquatic productTransport engineering

A multifunctional aquaculture platform comprises a main console, an auxiliary console, breeding devices and a mobile work vehicle; the main console includes a working platform, a first transport platform and a first guide rail; the working platform is provided with a hoisting machine and is connected to the first transport platform, and the first guide rail is laterally mounted on the first transport platform; the first guide rail is provided with a plurality of longitudinally spaced steel plates; the auxiliary console includes a plurality of second transport platforms and a second guide rail;the second transport platforms are longitudinally spaced on the left and right sides of the first transport platform, and are connected with the steel plates at the front end; the second guide rail is mounted on the second transport platform; the breeding devices are installed on both sides of the second transport platform; and the mobile work vehicle moves on the main console and the auxiliary console by the first guide rail and the second guide rail. The aquaculture platform can not only carry out the daily breeding activities of the pond, but also carry out corresponding scientific research activities, and has high flexibility, realizing the integration of the breeding function and the testing function.

Owner:佛山市南海通威水产科技有限公司

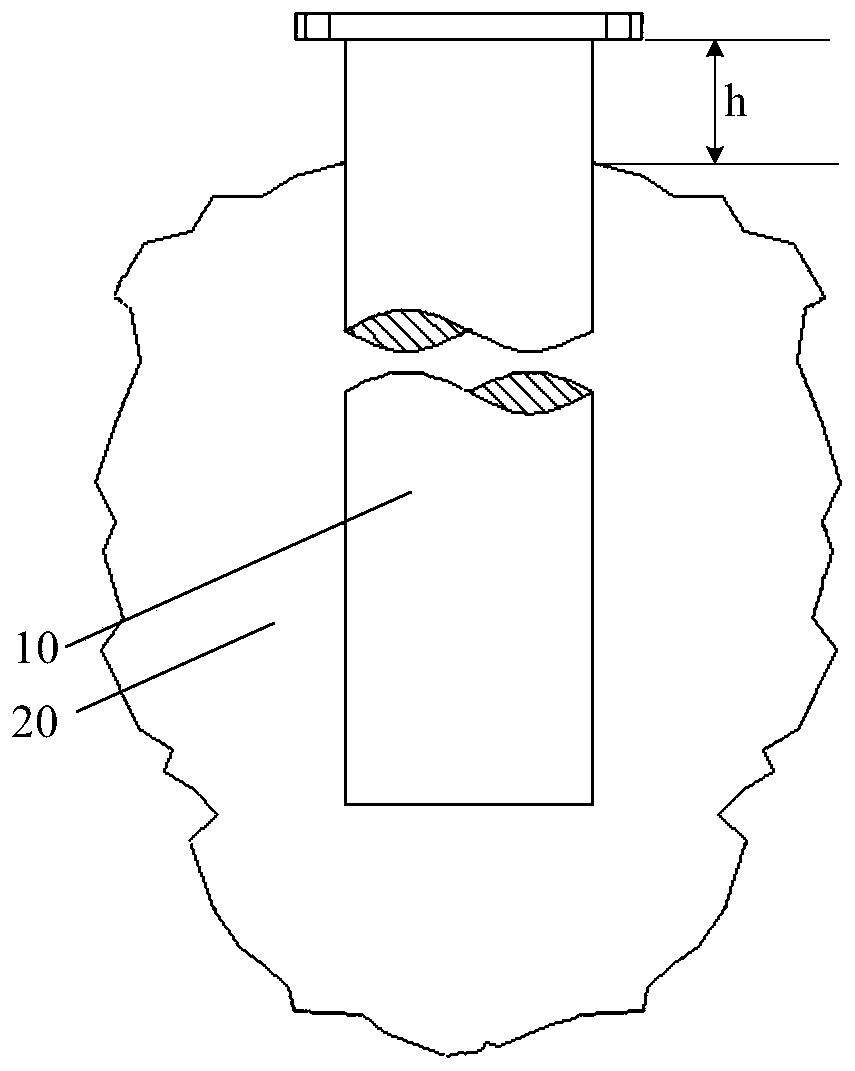

Dismantling method for building component

ActiveCN110878645ARealize openingImplement fixed functionUsing liquid separation agentBuilding repairsArchitectural engineeringWorking environment

The invention discloses a dismantling method for a building component. The dismantling method comprises the following steps that building component dismantling equipment runs in place, and hole forming work of static cutting drill bits and water spray work of raise dust prevention water spray devices are carried out; the static cutting drill bits are taken back, telescopic fixed pins stretch out,a mechanical arm is adjusted, so that a fixed device moves till the telescopic fixed pins are matched with holes, and the telescopic fixed pins are inserted into the holes and are fixed firmly; and cutting work of the building component is carried out, and after the building component and a body structure are completely separated, the building component is moved way through the building componentdismantling equipment. By means of the dismantling method, through the building component dismantling equipment, the functions of hole forming, fixing and transporting of the building component are achieved; compared with multi-type combined work, the integration degree is high, construction cost is reduced, and construction efficiency is improved; and meanwhile, through the arrangement of the raise dust prevention water spray devices, dust can be effectively prevented from flying off, and the green and healthy work environment is achieved.

Owner:SHANGHAI NO 4 CONSTR

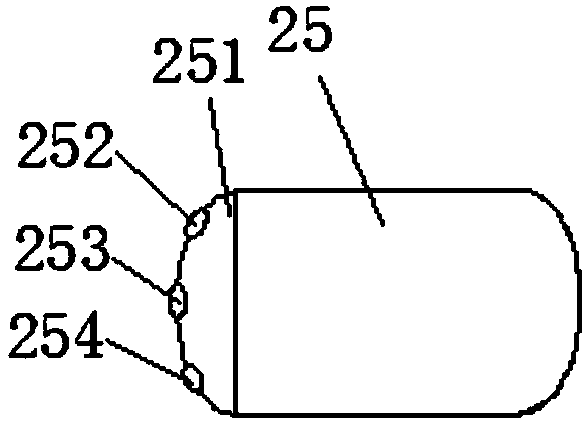

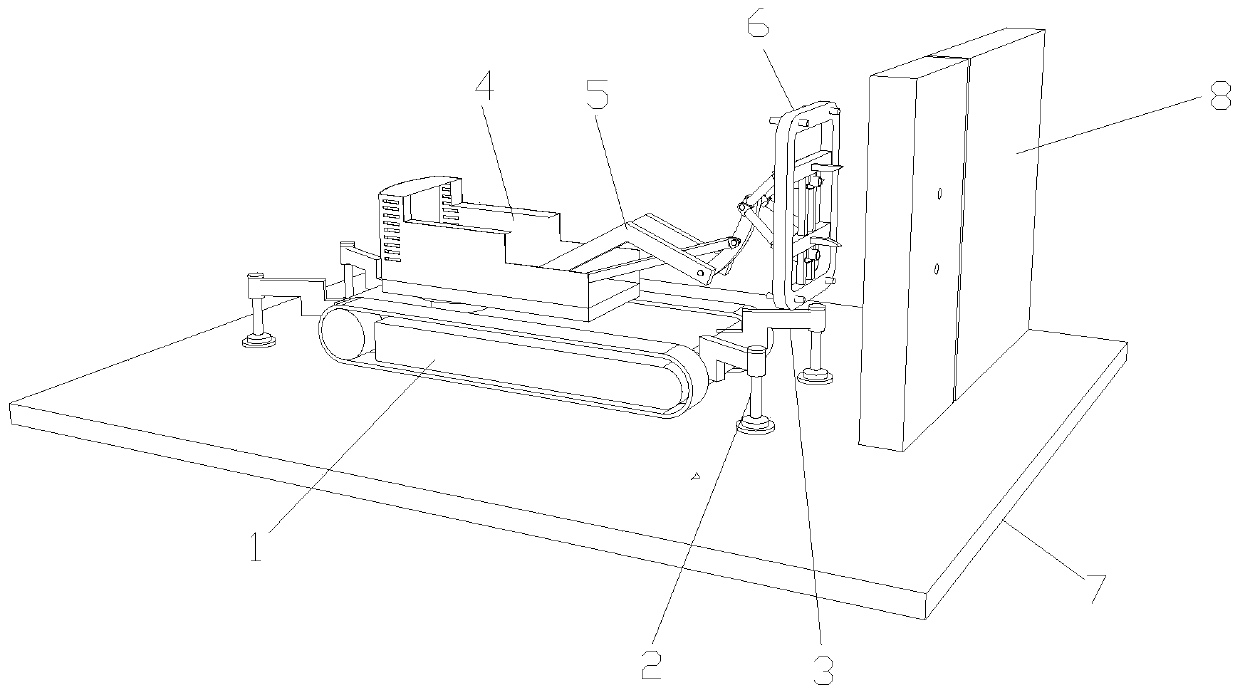

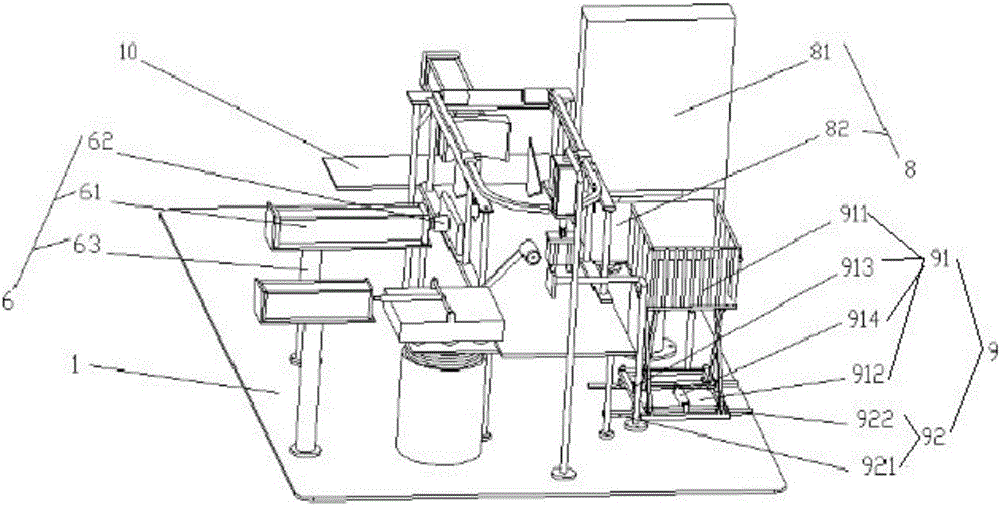

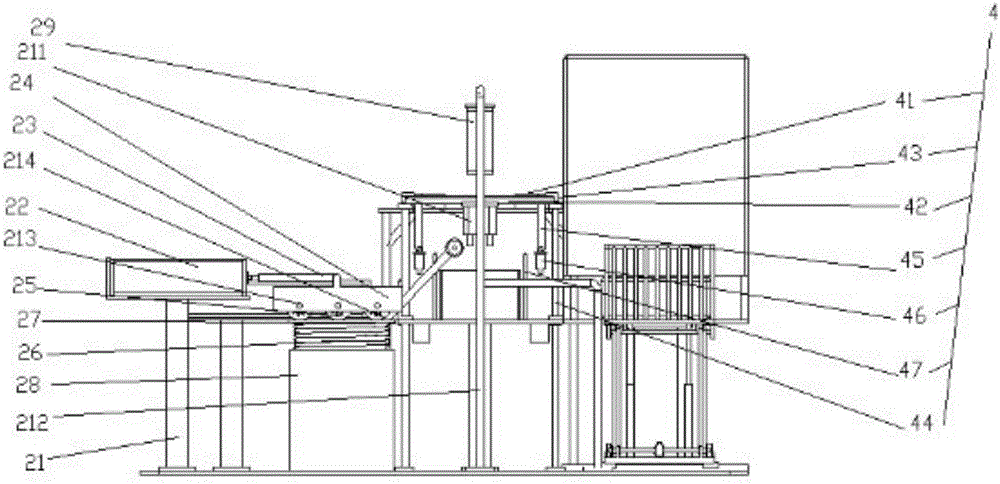

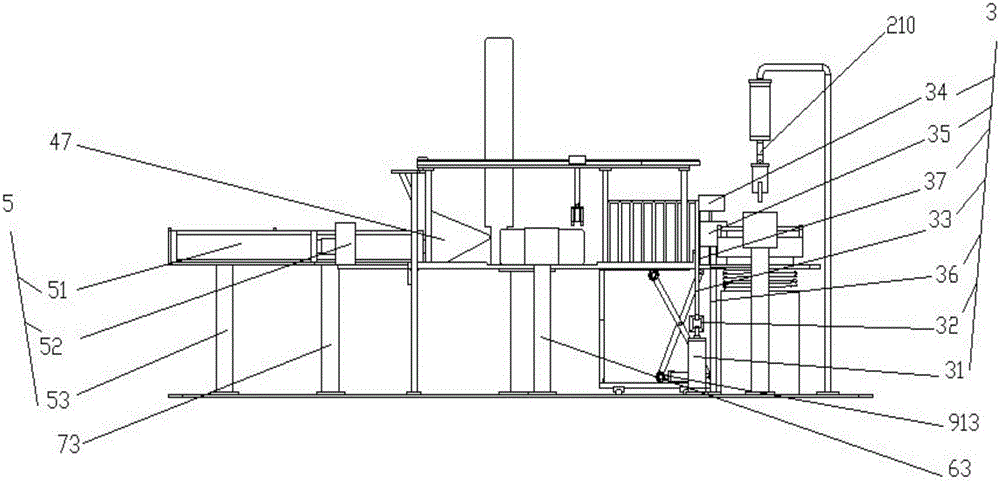

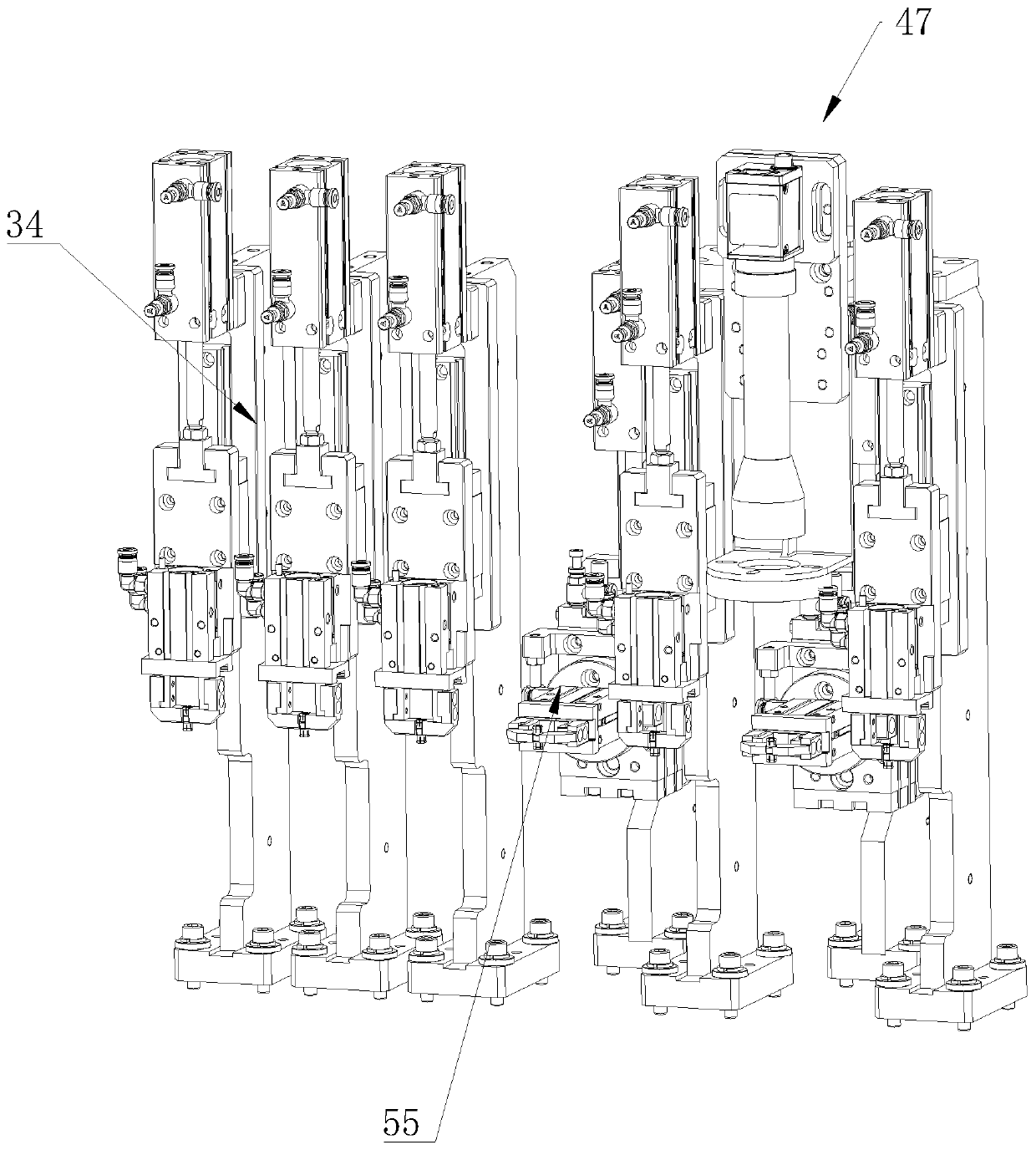

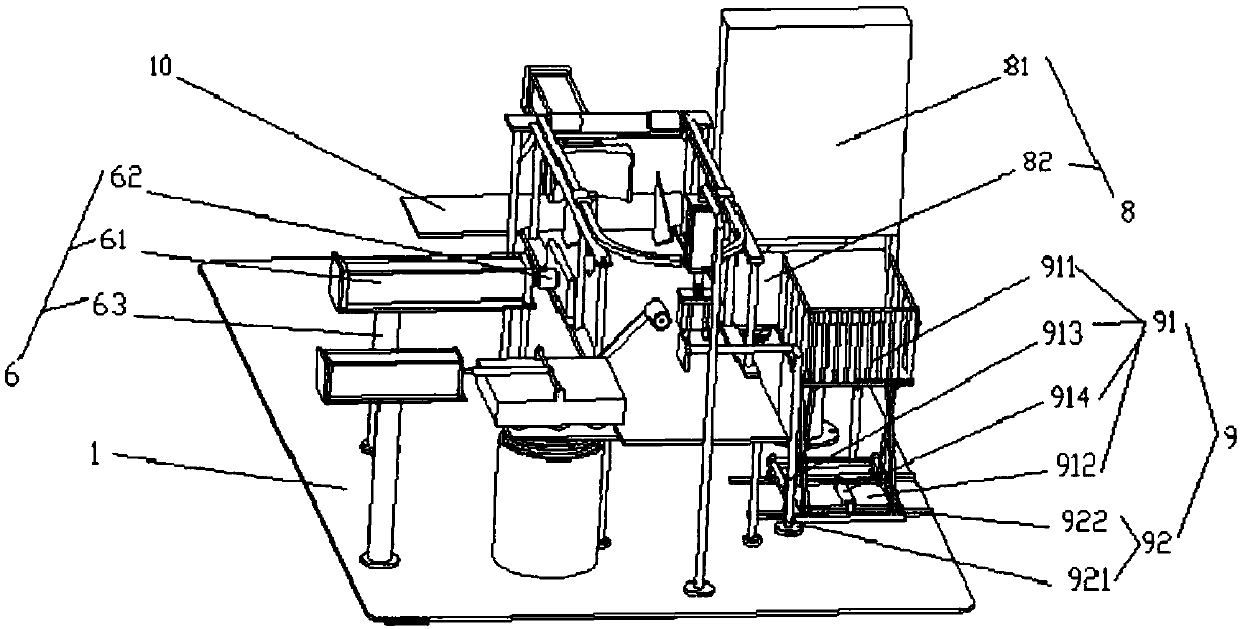

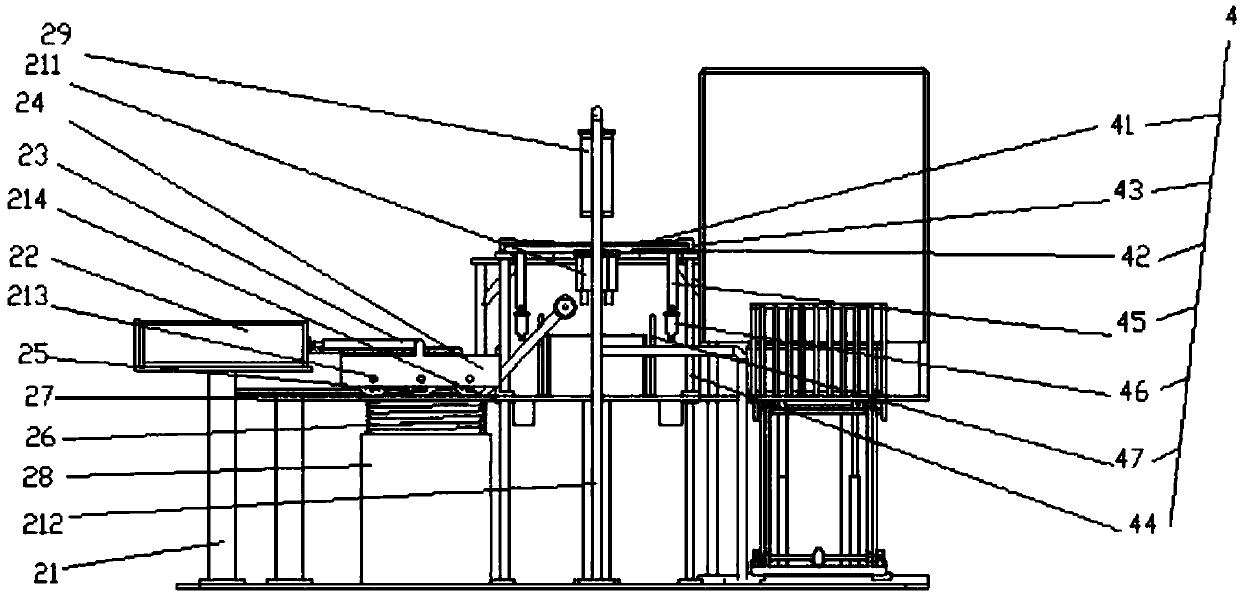

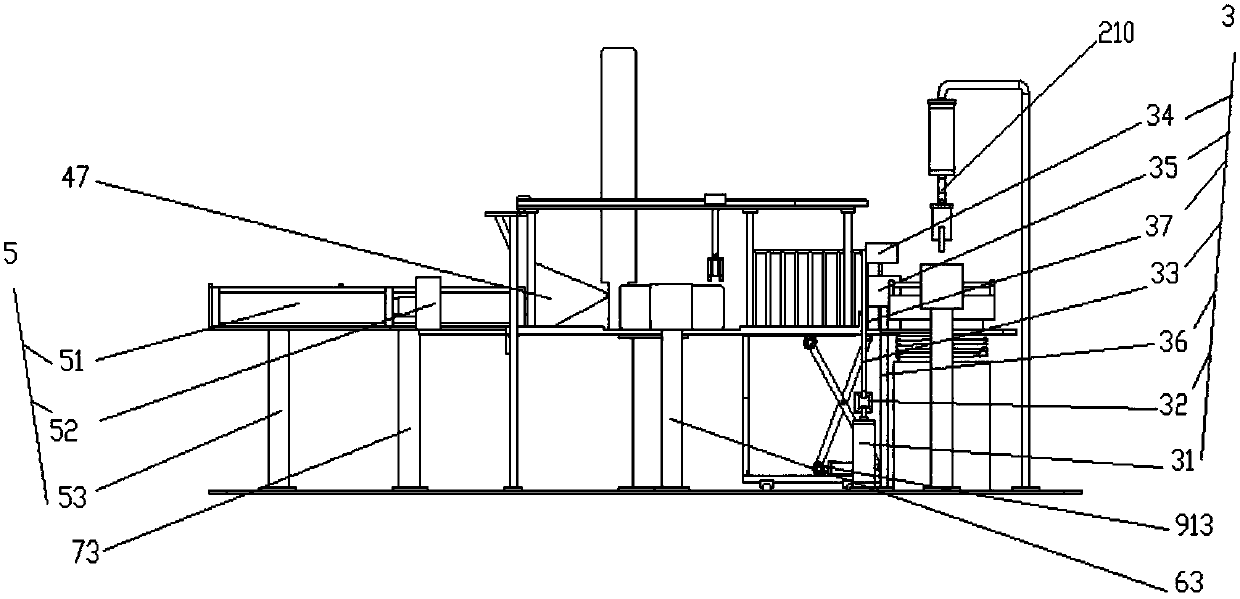

Fully-automatic friction bag taking type spindle packaging and transporting device

ActiveCN105857742AAvoid difficultiesRealize the transportation functionWrapper twisting/gatheringIndividual articlesEngineeringFully automatic

The invention relates to a fully-automatic friction bag taking type spindle packaging and transporting device which comprises a machine frame, a bag taking device, an opening device, a bag opening device, a bagging device, a pushing device I, a pushing device II, a sealing device and a transporting device, wherein the bag taking device takes out a packaging bag, the opening device opens a bag mouth of the packaging bag, the bag opening device fixes and opens the packaging bag of which the bag mouth is opened, the bagging device pushes plastic-packaged spindles into the packaging bag, the pushing device I pushes the filled packaging bag to the sealing device after the packaging bag is filled, the pushing device II pushes the sealed packaging bag into the transporting device after the packaging bag is sealed, and the transporting device transports the packaging bag filled with the spindles to a designated storage area in a warehouse. The fully-automatic friction bag taking type spindle packaging and transporting device provided by the invention realizes the full automation of bag taking, bag opening, bagging, bag pushing, bag sealing and transportation in the packaging process of the spindles, saves labor, reduces the production cost and improves the production efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

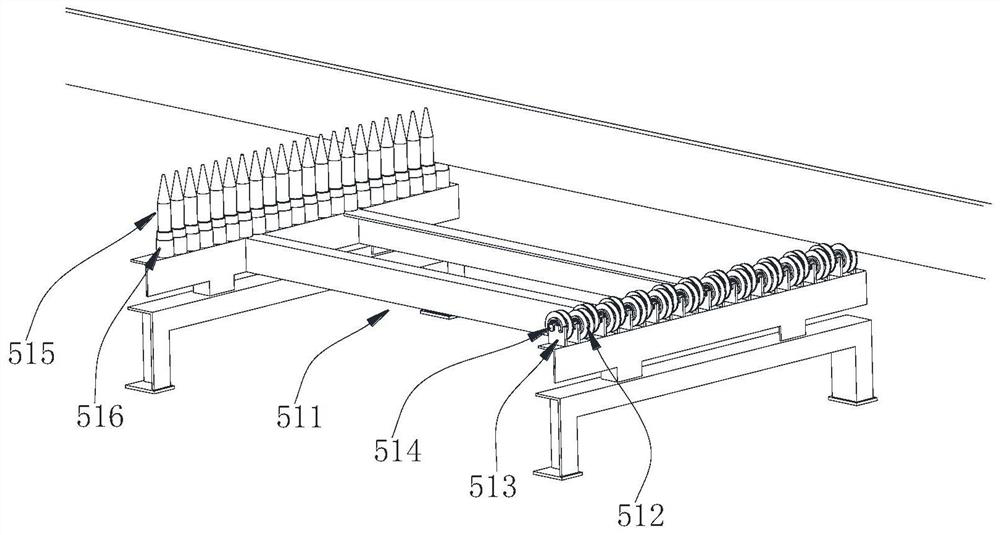

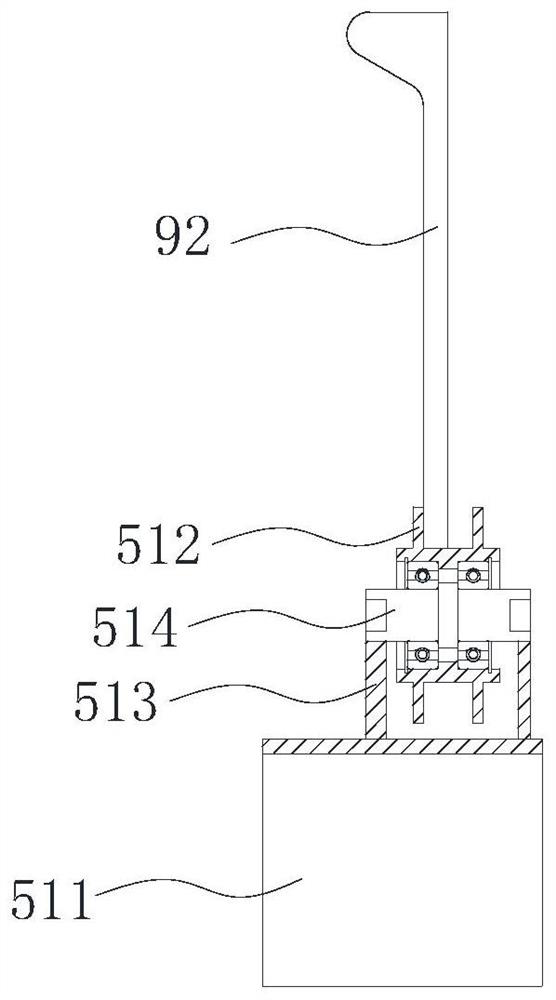

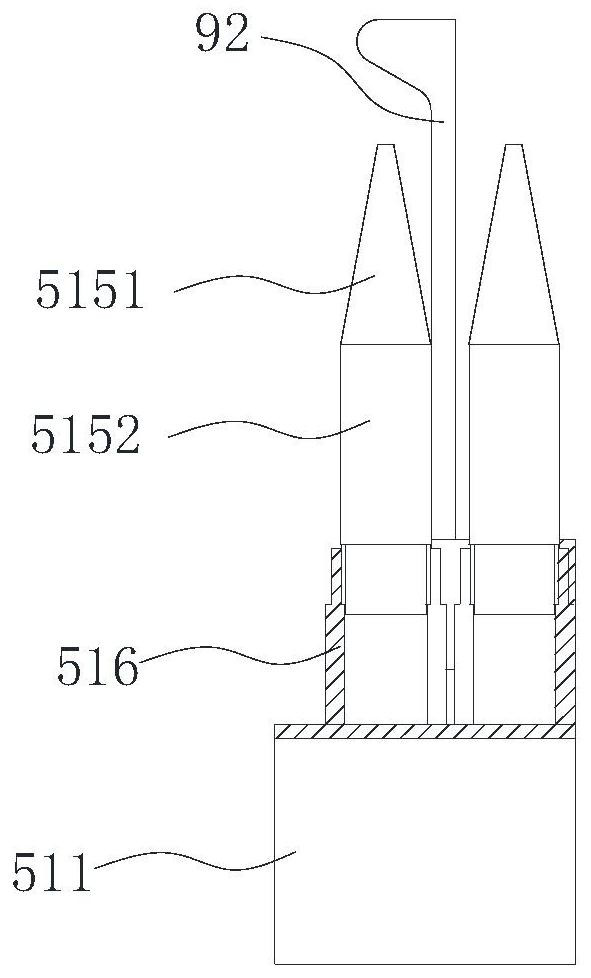

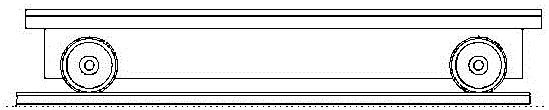

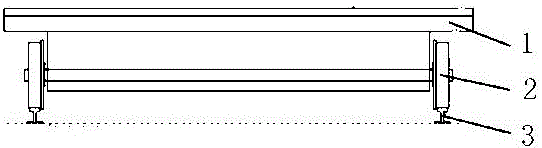

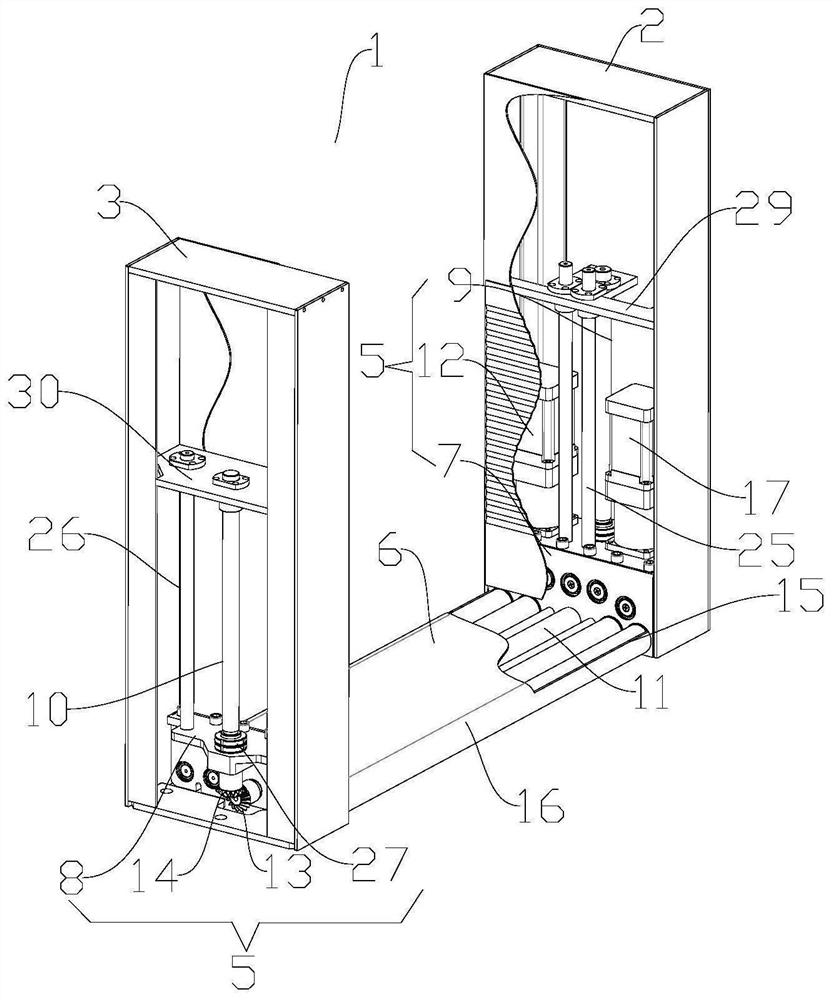

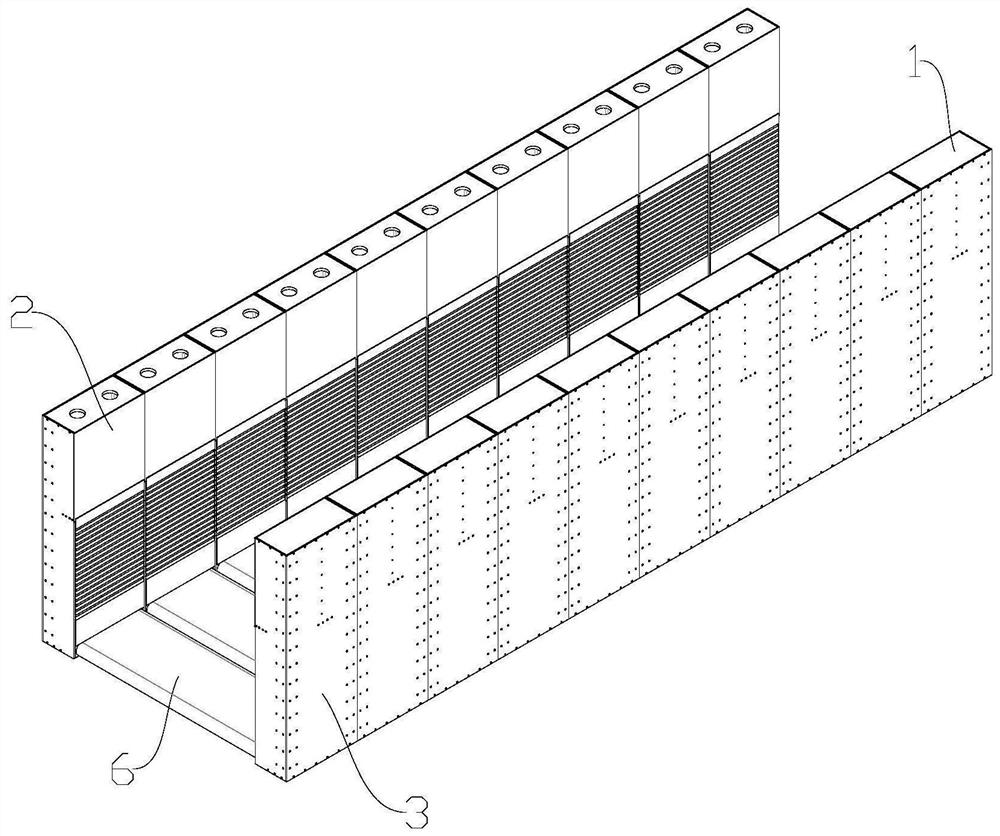

Flat-bulb steel storage equipment, storage and transportation device and transportation method

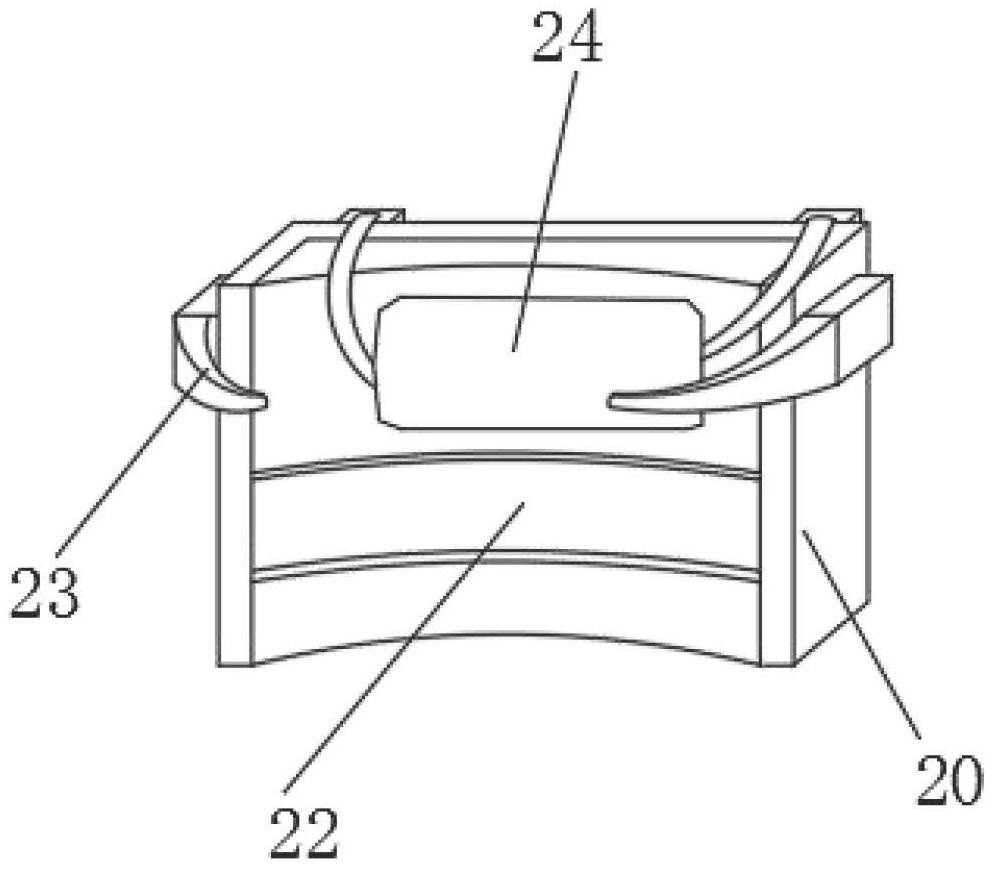

InactiveCN111619759AAvoid stackingAvoid squeezingWaterborne vesselsStructural engineeringMechanical engineering

The invention provides flat-bulb steel storage equipment, a storage and transportation device and a transportation method. The flat-bulb steel storage equipment comprises a plurality of bottom rollersand a plurality of side carrier rollers. The plurality of bottom rollers are transversely arranged in parallel at intervals; each bottom roller rotates around a transverse direction, and an accommodating groove for supporting flat-bulb steel is annularly formed in an outer peripheral surface of each bottom roller; the plurality of side carrier rollers are transversely arranged in parallel at intervals; the side carrier rollers and the bottom rollers are arranged at intervals in a longitudinal direction, and all the side carrier rollers rotate around a vertical direction; and a gap is formed between every two adjacent side carrier rollers so that the two side carrier rollers and the corresponding bottom rollers jointly support the flat-bulb steel extending in the longitudinal direction. When the storage equipment is used for storing the flat-bulb steel, the flat-bulb steel is contained in the accommodating groove of each bottom roller, the flat-bulb steel is contained between every twoadjacent side carrier rollers, stacking and extrusion of the flat-bulb steel are avoided, deformation of the flat-bulb steel is further avoided, and the precision of the flat-bulb steel is guaranteed.

Owner:LONGKOU CIMC RAFFLES OFFSHORE +4

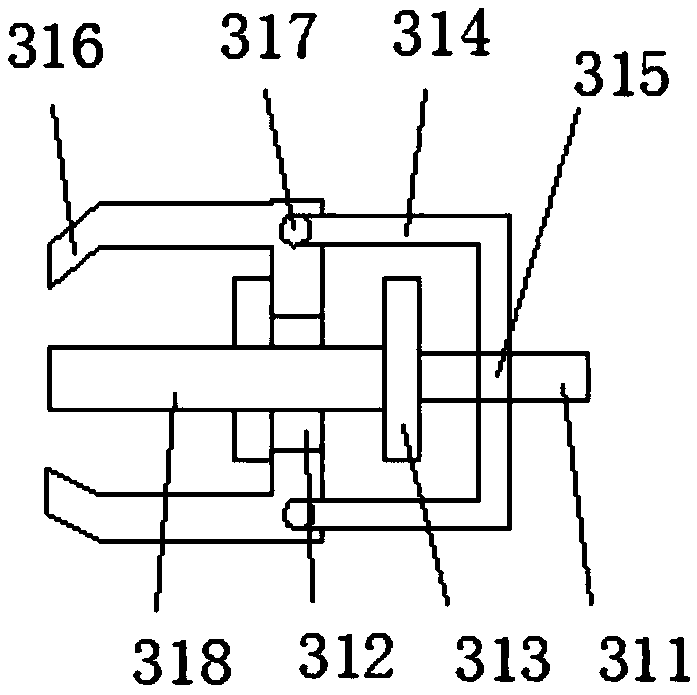

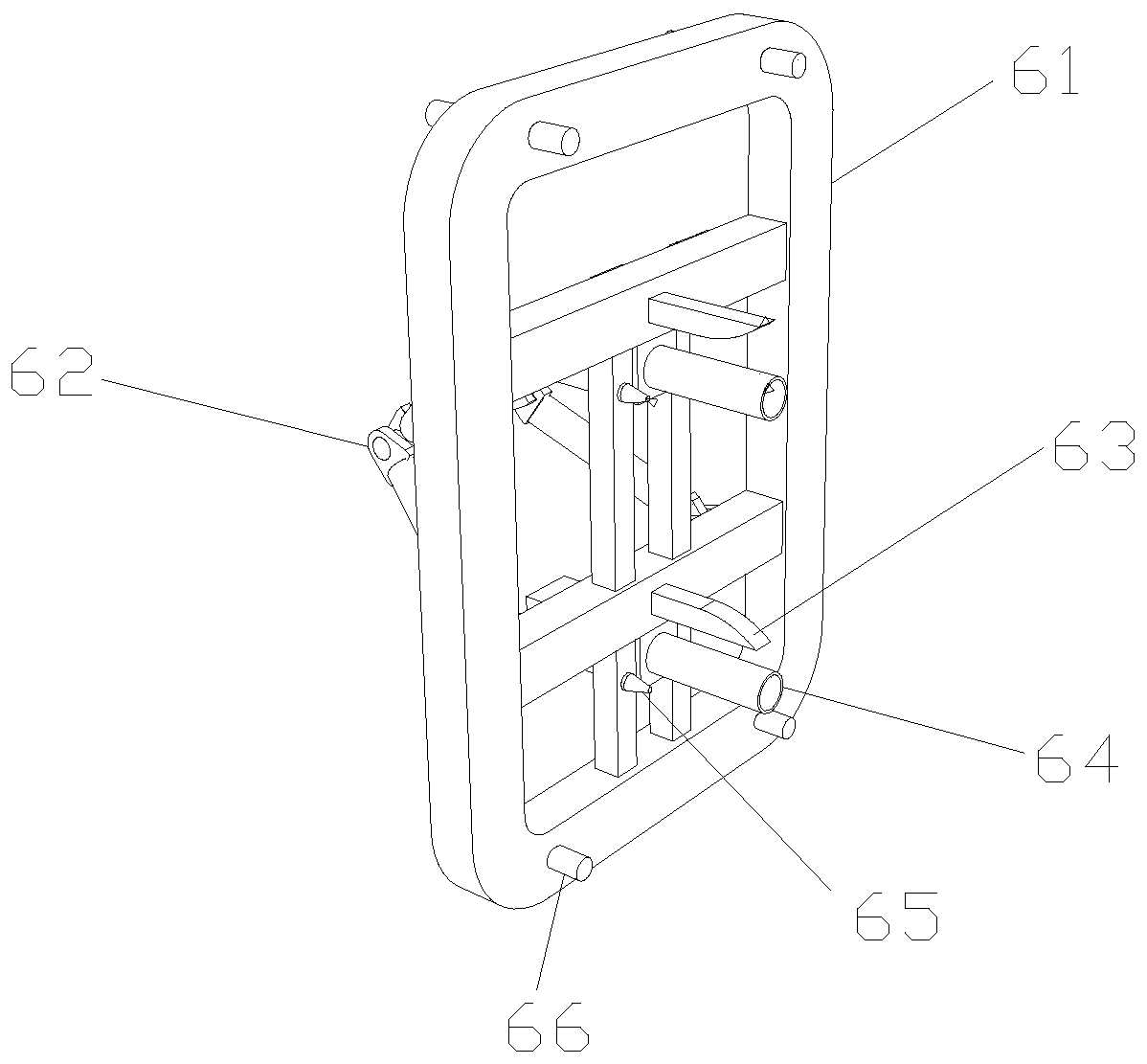

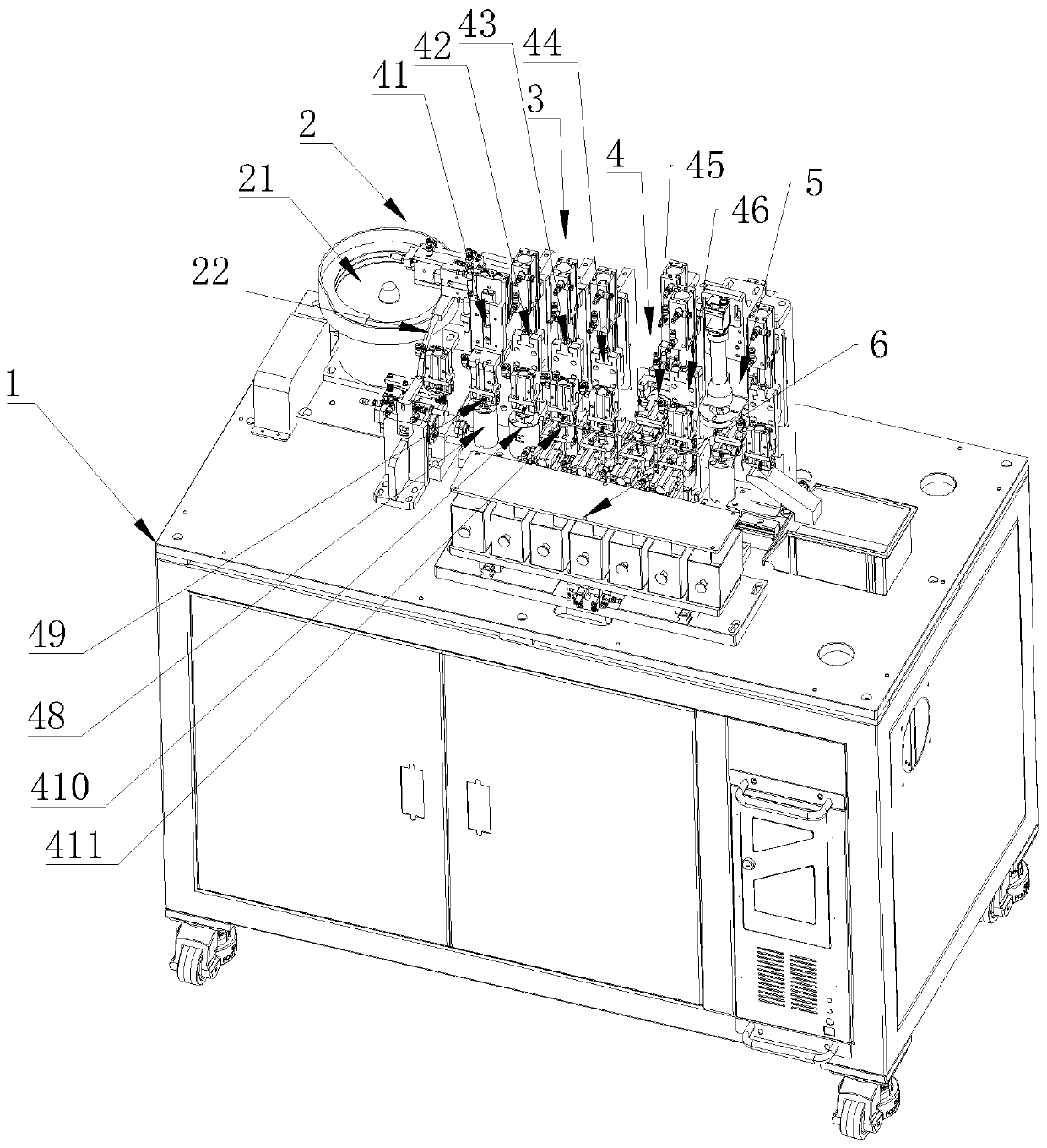

Terminal detector

ActiveCN111229645ARealize the transportation functionImprove detection efficiencySortingComputer hardwareElectrical and Electronics engineering

The invention discloses a terminal detector. According to the technical scheme, the terminal detector comprises a machine frame. A feeding mechanism, a carrying mechanism, a performance detecting mechanism, an image detecting mechanism and a reject recovering mechanism are arranged on the machine frame sequentially. According to the scheme, the automatic feeding, carrying, performance detecting, visual detecting and reject classifying and recovering can be realized, and the terminal detecting efficiency and accuracy can be improved.

Owner:苏州领策精工科技有限公司

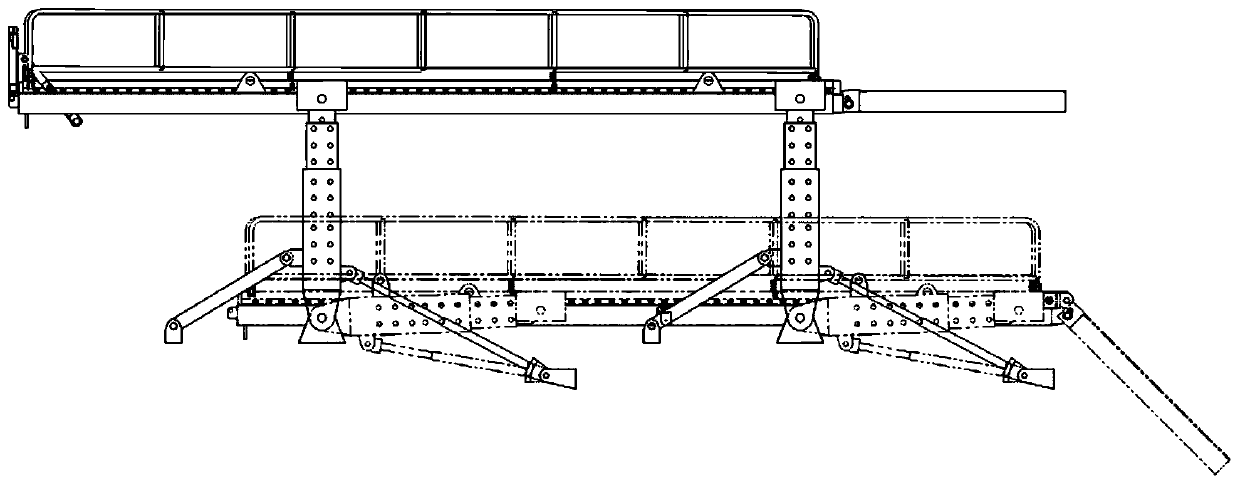

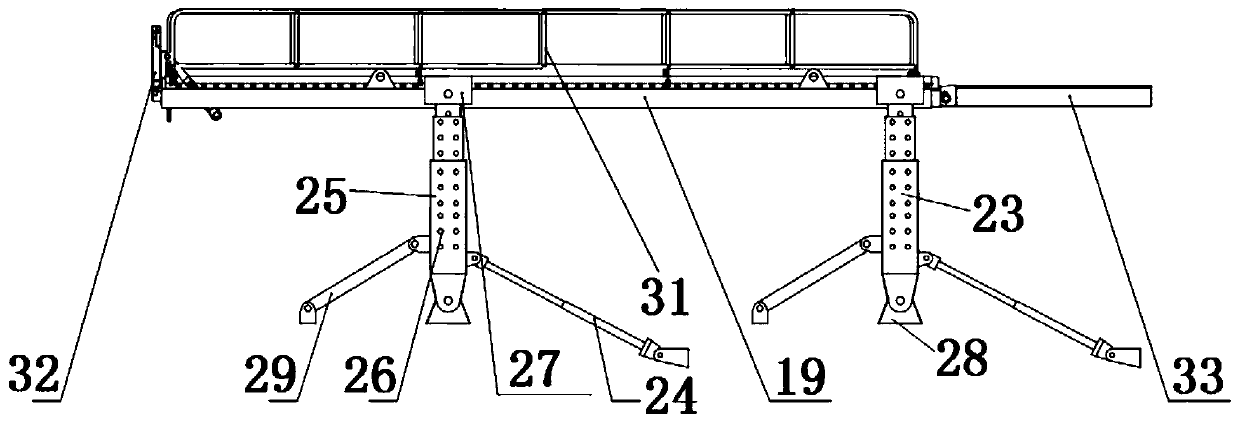

End underframe lifting device for automobile-container dual-purpose concave-bottom transport vehicle

PendingCN111391875AAvoid collisionSolve the defect that only cars can be transportedAxle-box lubricationWagons/vansRail transportationTransportation cost

Owner:CRRC MEISHAN

A pretreatment device for electrophoretic spray paint on the surface of mechanical parts

ActiveCN107904648BImprove work efficiencyImplement the placement functionElectrophoretic coatingsMechanical componentsElectrophoresis

The invention discloses an electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings. The electrophoresis paint-spraying pretreatment device comprises a housingI, wherein an inner cavity of the housing I is hollow; the bottom wall of the housing I is sequentially connected with a motor I, a motor II and a motor III in the horizontal direction; one end of themotor I, one end of the motor II and one end of the motor III are separately connected with a rotary shaft I, a rotary shaft II and a rotary shaft III; the top of the housing I is sequentially connected with a conveyor belt I, a controller, a frame body, a water tank, a barrel body, a supporting rod, a booster pump, a housing II, an electrophoresis slot and a conveyor belt II in the horizontal direction; one end, away from the housing I, of the conveyor belt I is fixedly connected with a placing plate; the placing plate is positioned on the top of the water tank; and the side wall of one side, away from the conveyor belt, of the water tank is sequentially connected with a water pump and a water introducing tube in the vertical direction. The electrophoresis paint-spraying pretreatment device is simple in structure, is convenient to operate, realizes pretreatment for electrophoresis parts and fittings and a treatment function after electrophoresis is completed, and improves electrophoresis quality.

Owner:ANHUI POLYTECHNIC UNIV

Fire fighting device for a chemical plant

ActiveCN112870603BAvoid defects that require dumpingAvoid the pitfalls of dumpingFire rescueDirt cleaningEngineeringProcess engineering

The invention discloses a fire-fighting device for a chemical plant in the field of fire-fighting engineering. The pressure suction layer includes an opening, a negative pressure machine and a smoke sensor. The opening is located on the surface of the column-type cabinet. A storage chamber is formed between the opening and the negative pressure machine. There is a one-way air intake valve at the opening, and the smoke The sensor is used to control the opening of the negative pressure machine. The smoke sensor drives the negative pressure machine to absorb the external smoke. At this time, the smoke enters the storage chamber. When the smoke and air flow in the storage chamber increase, the pressure in the storage chamber When it rises, the vibration layer is gradually lifted, which realizes the absorption of toxic smoke and reduces the possibility of people around the device being blocked by smoke.

Owner:SHANDONG GUOTAI TECH

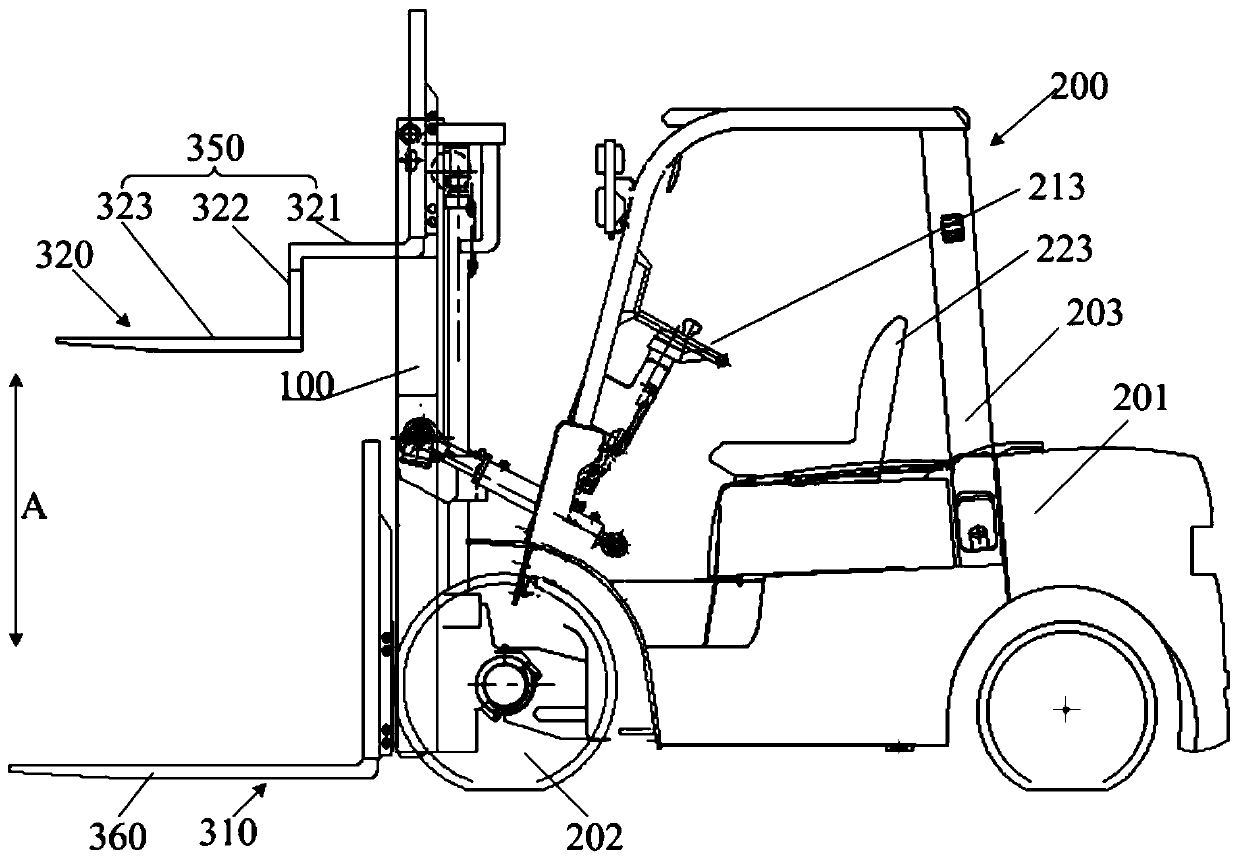

Forklifts and electrolytic transporters

ActiveCN108238569BIncreased flexibility of useRealize the transportation functionLifting devicesElectrolysisStructural engineering

The invention provides a forklift and an electrolysis transportation device. The forklift comprises a vehicle body, a lifting supporting frame, a first fork arm structure and a second fork arm structure; the lifting supporting frame is arranged on the vehicle body; the first fork arm structure is arranged on the lifting supporting frame, and can move along the lifting supporting frame; and the second fork arm structure is arranged on the lifting supporting frame. According to the forklift, the first fork arm structure and the second fork arm structure are arranged on the lifting supporting frame, and the first fork arm structure can move along the lifting supporting frame, so that compared with a forklift provided with only one fork arm structure, the forklift has the advantages that the use range is wider, the use flexibility is higher, both the first fork arm structure and the second fork arm structure can enable the forklift to achieve the transportation function, and the differentactual transportation requirements can be met by moving the first fork arm structure to a corresponding position along the lifting supporting frame; and in addition, when the first fork arm structuremoves to the horizontal plane same as the horizontal plane of the second fork arm structure, a double-fork-arm structure can be formed in the horizontal plane direction, and the stability of the forklift in the transportation process can be improved.

Owner:哈尔滨博睿创富新材料有限公司

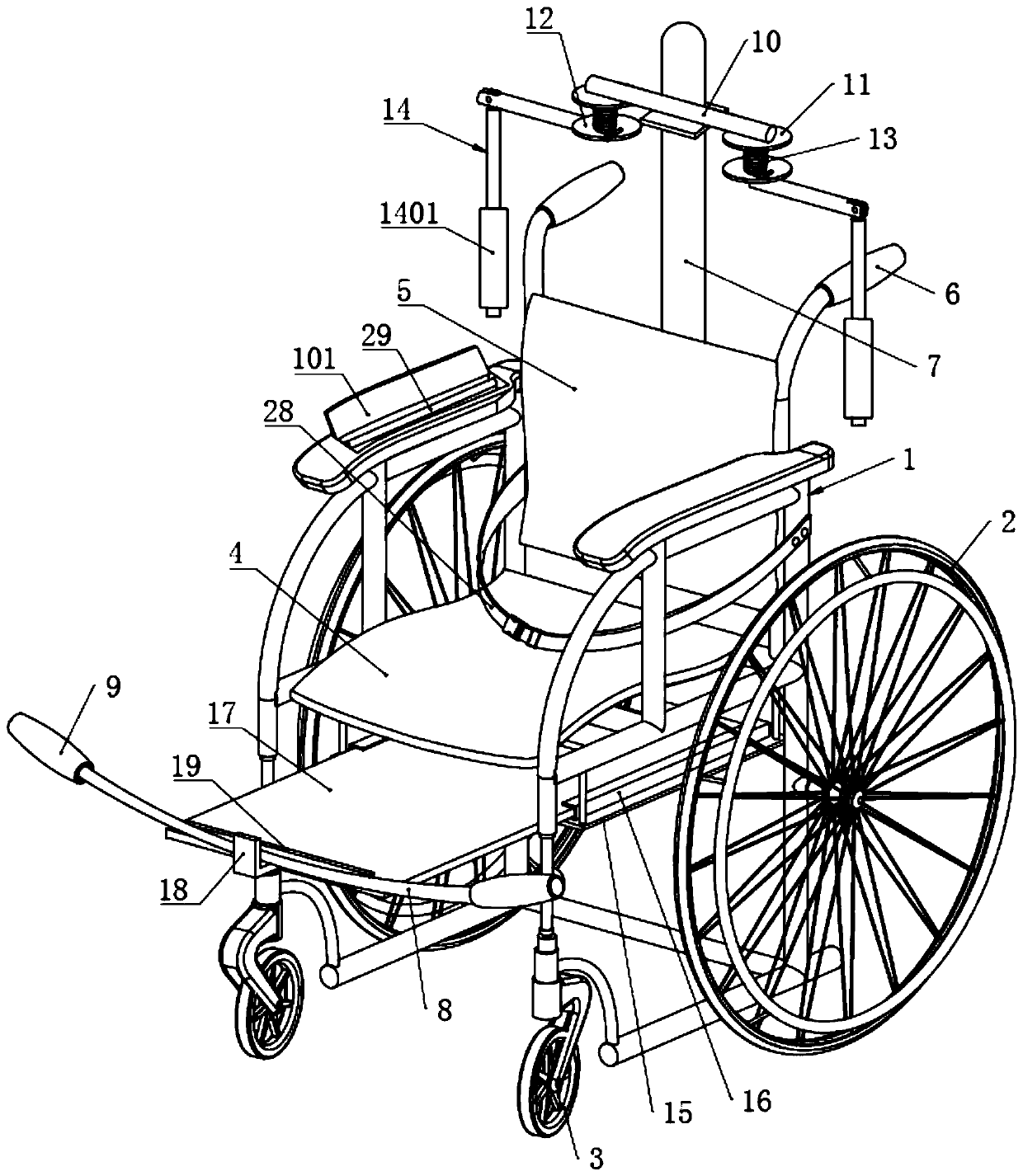

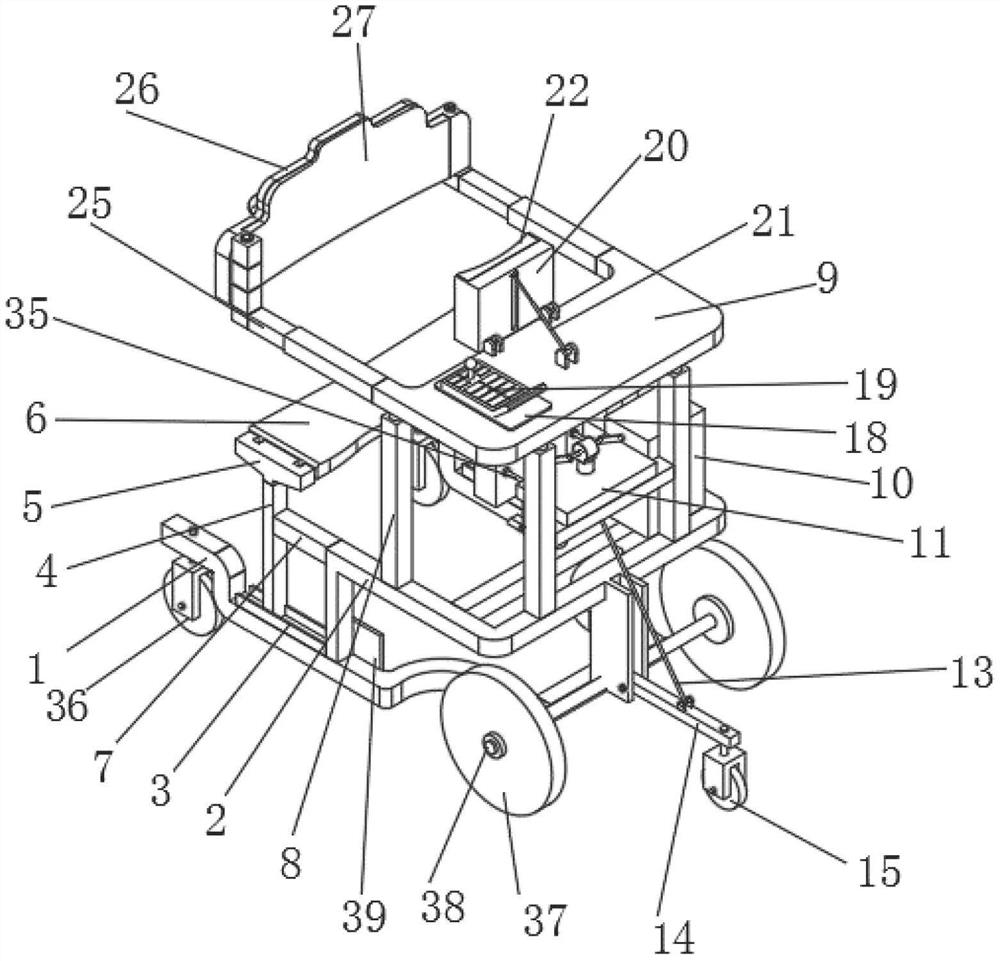

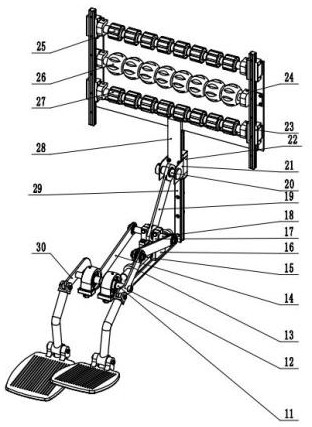

Multifunctional rehabilitation wheelchair

PendingCN112790918ARealize the transportation functionQuick changeWheelchairs/patient conveyanceWalking aidsPhysical medicine and rehabilitationWheelchair

The invention discloses a multifunctional rehabilitation wheelchair, which comprises a basic frame, a leg training device, a transmission device and a back massage device, and has the beneficial effects that the multifunctional rehabilitation wheelchair not only can realize the function of riding instead of walking of a common wheelchair, but also can perform leg rehabilitation training, and can perform back massage according to requirements while performing rehabilitation training; massage rods of different models can be rapidly replaced according to the requirements for different massage strengths, operation is easy and rapid, and the multifunctional rehabilitation wheelchair is achieved through a simple mechanical structure and is low in cost and high in popularization value.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

A control method, vehicle frame, power drive assembly and vehicle

ActiveCN107161260BReduce economic pressureHas racing featuresSpeed controllerMotorised scootersVehicle frameControl engineering

The invention discloses a control method, a vehicle frame, a power drive assembly and a vehicle, the vehicle frame is used for connecting with the power drive assembly, and the vehicle frame has a controller and a manipulation assembly for controlling the power drive assembly , the method includes: after the vehicle frame is connected to the power drive assembly and the controller establishes a communication connection with the power drive assembly, the controller detects a manipulation instruction from the manipulation assembly; the When the controller detects that the manipulation command from the manipulation component is obtained and determines that the manipulation command corresponds to the power drive component, it generates a control command for controlling the power drive component according to the manipulation command, and sends the A control command is sent to the power drive assembly.

Owner:NINEBOT (BEIJING) TECH CO LTD

Combined truck

ActiveCN106218741BHandling safetyRealize the transportation functionEndless track vehiclesPower stationGravity center

The invention discloses a combined type loading carrier. The combined type loading carrier comprises two supporting assemblies. Each supporting assembly comprises a supporting frame and two crawler type moving devices, wherein the supporting frame comprises two parallel supporting plates and a first connecting plate; the two ends of the first connecting plate are fixed to the supporting plates through bolts; the two crawler type moving devices are mounted on the lower portions of the supporting plates correspondingly. The two supporting assemblies are mutually connected through a second connecting plate. The two ends of the second connecting plate are fixed to the side walls of the supporting plates of the corresponding supporting assembly through bolts. All the parts are fixed through the bolts, dismounting and mounting are convenient, the parts can be flexibly and conveniently combined according to the shapes of workpieces, splitting is facilitated, and the combined type loading carrier is dismounted into small parts and taken to the field for assembling; and the crawler type moving devices are also called crawler type rolling wheel trolleys or ground tanks or carrying tanks and the like, the loading capacity of the crawler type moving devices is large, the gravity center is low, and the combined type loading carrier can achieve carrying safely in limited spaces, for example, the combined type loading carrier can be used in environments limited by corridors and pipelines, such as power station machine rooms.

Owner:远大工控技术(杭州)有限公司

Container with folding telescopic structure

PendingCN112141544AIncreased loading spaceRealize the transportation functionLarge containersStructural engineeringMoving frame

Owner:深圳市欣禾车联网技术装备有限公司

Combined type loading carrier

The invention discloses a combined type loading carrier. The combined type loading carrier comprises two supporting assemblies. Each supporting assembly comprises a supporting frame and two crawler type moving devices, wherein the supporting frame comprises two parallel supporting plates and a first connecting plate; the two ends of the first connecting plate are fixed to the supporting plates through bolts; the two crawler type moving devices are mounted on the lower portions of the supporting plates correspondingly. The two supporting assemblies are mutually connected through a second connecting plate. The two ends of the second connecting plate are fixed to the side walls of the supporting plates of the corresponding supporting assembly through bolts. All the parts are fixed through the bolts, dismounting and mounting are convenient, the parts can be flexibly and conveniently combined according to the shapes of workpieces, splitting is facilitated, and the combined type loading carrier is dismounted into small parts and taken to the field for assembling; and the crawler type moving devices are also called crawler type rolling wheel trolleys or ground tanks or carrying tanks and the like, the loading capacity of the crawler type moving devices is large, the gravity center is low, and the combined type loading carrier can achieve carrying safely in limited spaces, for example, the combined type loading carrier can be used in environments limited by corridors and pipelines, such as power station machine rooms.

Owner:远大工控技术(杭州)有限公司

A friction bag-taking type spindle automatic packaging and transportation device

ActiveCN105857742BAvoid difficultiesRealize the transportation functionWrapper twisting/gatheringIndividual articlesEngineeringFully automatic

The invention relates to a fully-automatic friction bag taking type spindle packaging and transporting device which comprises a machine frame, a bag taking device, an opening device, a bag opening device, a bagging device, a pushing device I, a pushing device II, a sealing device and a transporting device, wherein the bag taking device takes out a packaging bag, the opening device opens a bag mouth of the packaging bag, the bag opening device fixes and opens the packaging bag of which the bag mouth is opened, the bagging device pushes plastic-packaged spindles into the packaging bag, the pushing device I pushes the filled packaging bag to the sealing device after the packaging bag is filled, the pushing device II pushes the sealed packaging bag into the transporting device after the packaging bag is sealed, and the transporting device transports the packaging bag filled with the spindles to a designated storage area in a warehouse. The fully-automatic friction bag taking type spindle packaging and transporting device provided by the invention realizes the full automation of bag taking, bag opening, bagging, bag pushing, bag sealing and transportation in the packaging process of the spindles, saves labor, reduces the production cost and improves the production efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

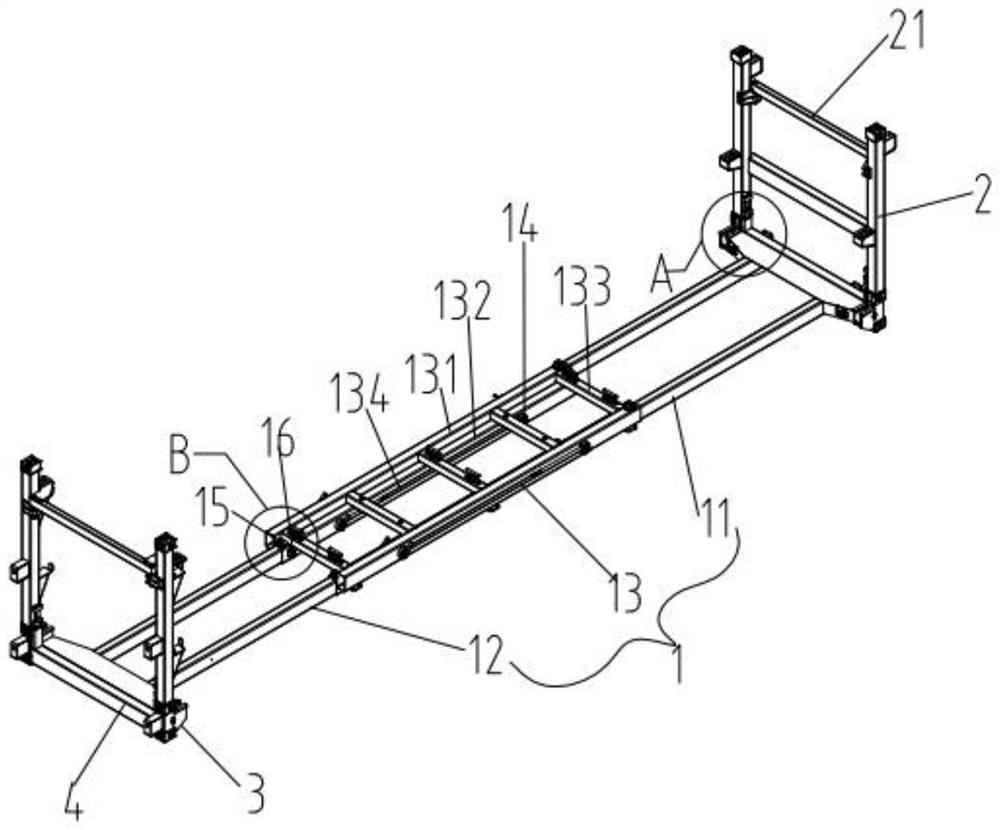

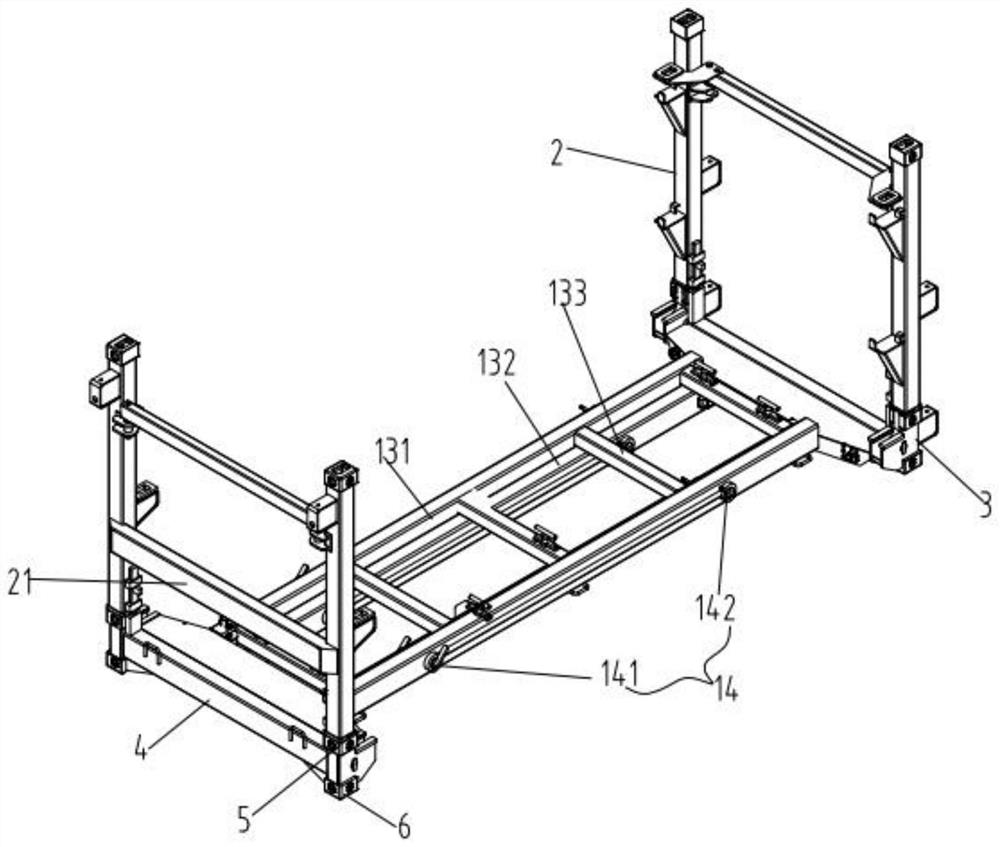

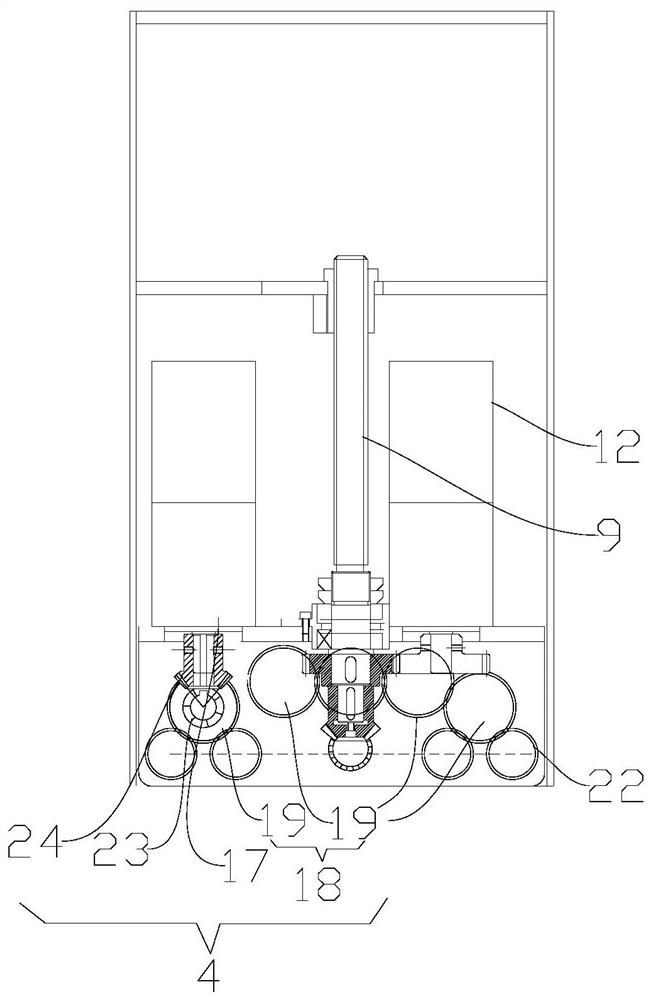

Automatic elevator equipment

PendingCN113120794AImproved shipping performanceEasily damagedConveyorsControl devices for conveyorsGear driveGear wheel

The invention provides automatic elevator equipment, and relates to the technical field of elevators. The automatic elevator equipment comprises a plurality of lifting bodies, each lifting body comprises a driving end frame, a driven end frame, a control module, a transmission assembly, a lifting assembly and a conveying assembly, each lifting assembly comprises a first lifting table, a second lifting table, a first T-shaped lead screw, a second T-shaped lead screw, a transmission rod and a lifting motor, the control modules are electrically connected with the lifting motors and the transmission assemblies, each conveying assembly comprises a knurling rolling shaft and a conveying belt arranged on the knurling rolling shaft in a covering mode, transmission gears are arranged at one ends of the knurling rolling shafts, and the transmission gears are connected with the transmission assemblies.The automatic elevator equipment has the advantages of being good in conveying effect, small in occupied area and high in applicability.

Owner:武汉右方科技有限公司

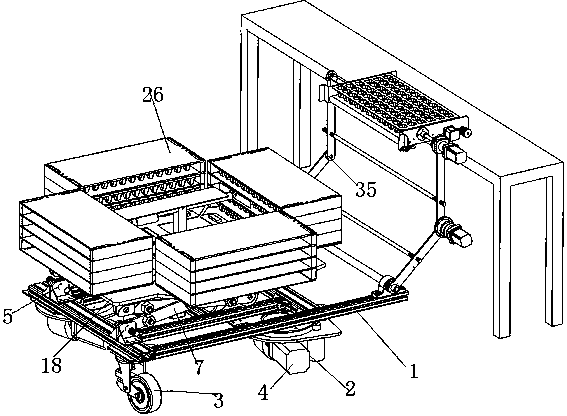

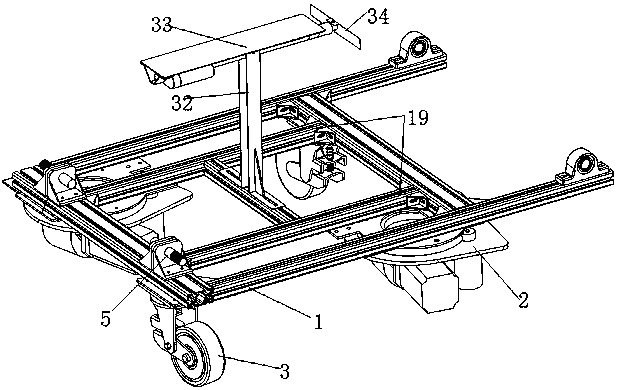

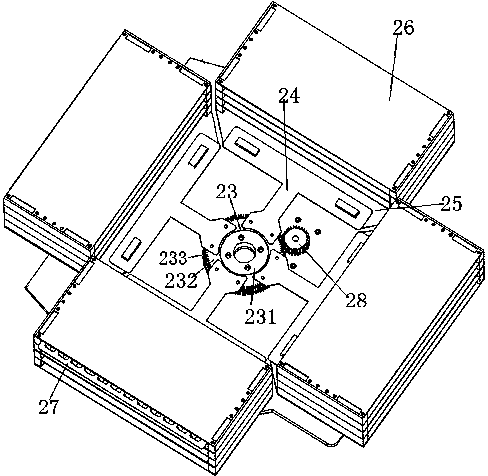

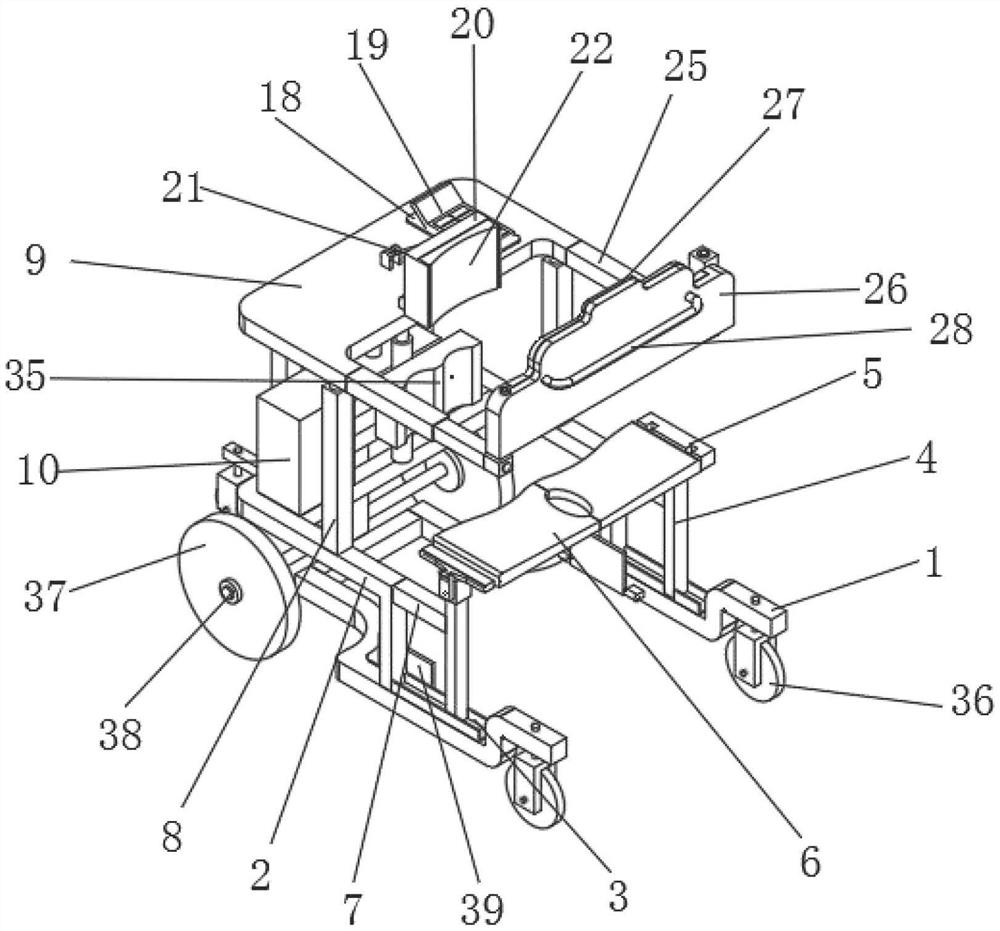

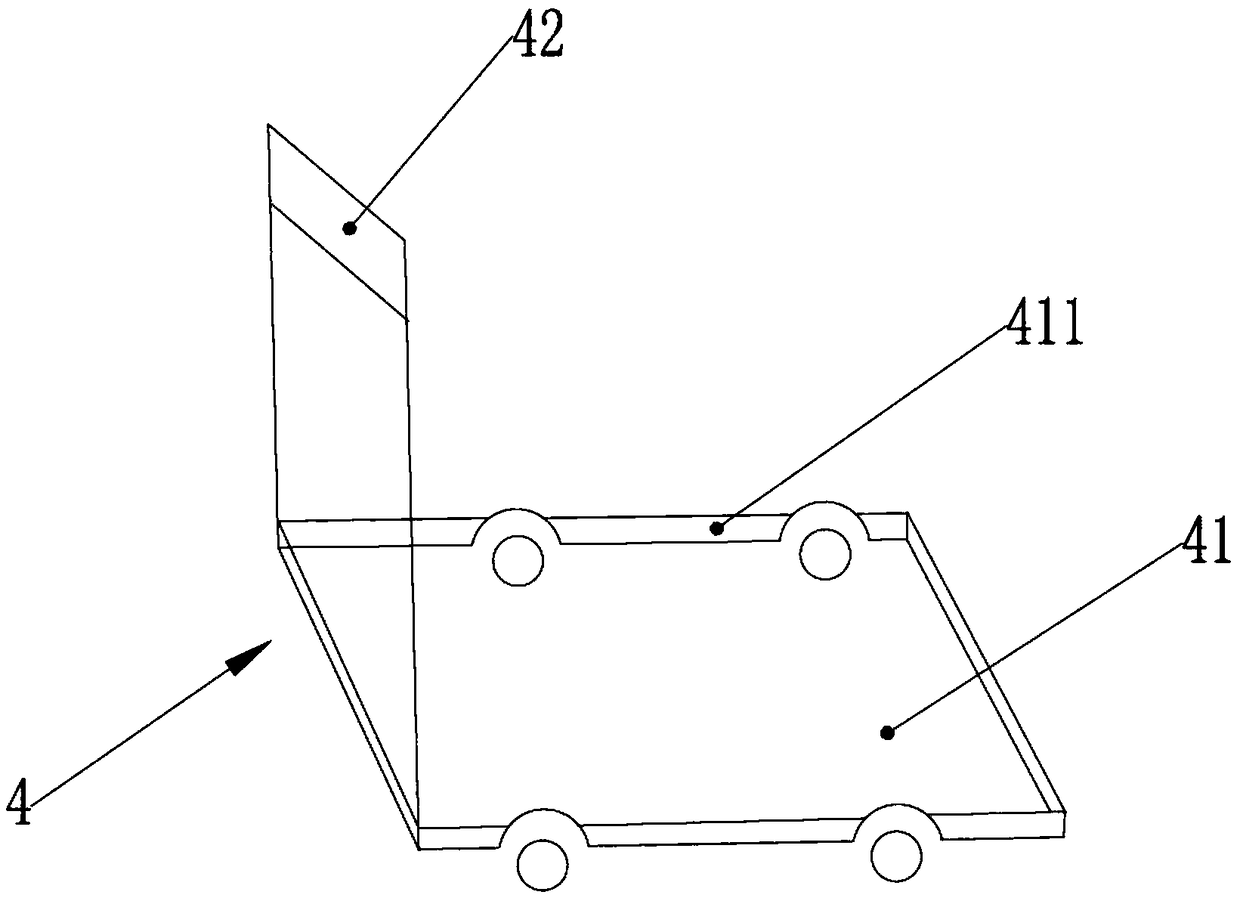

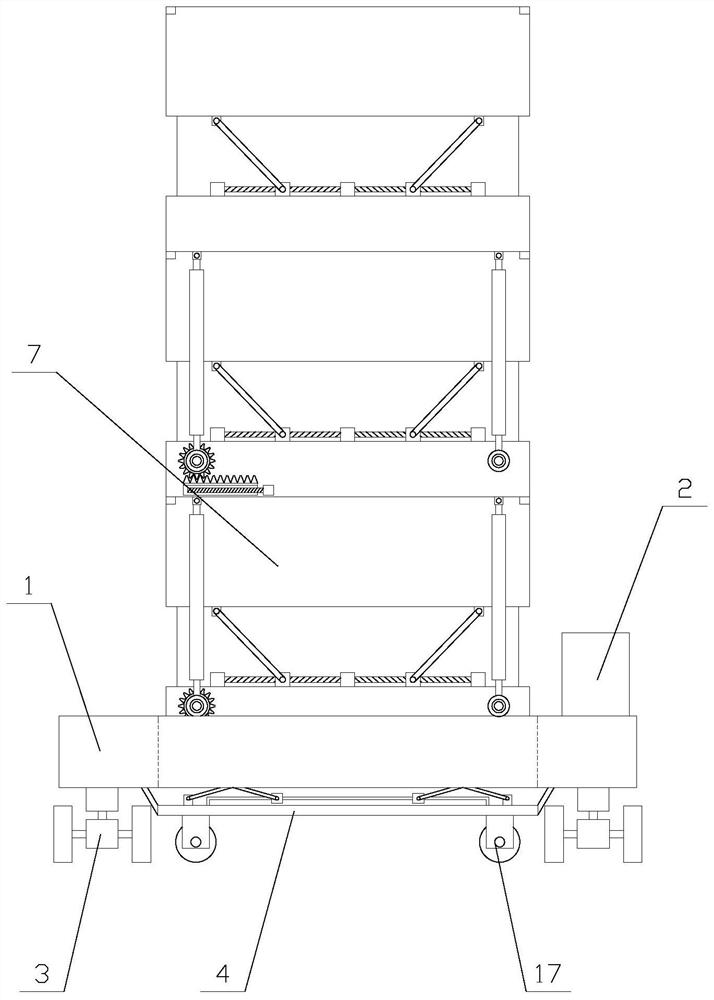

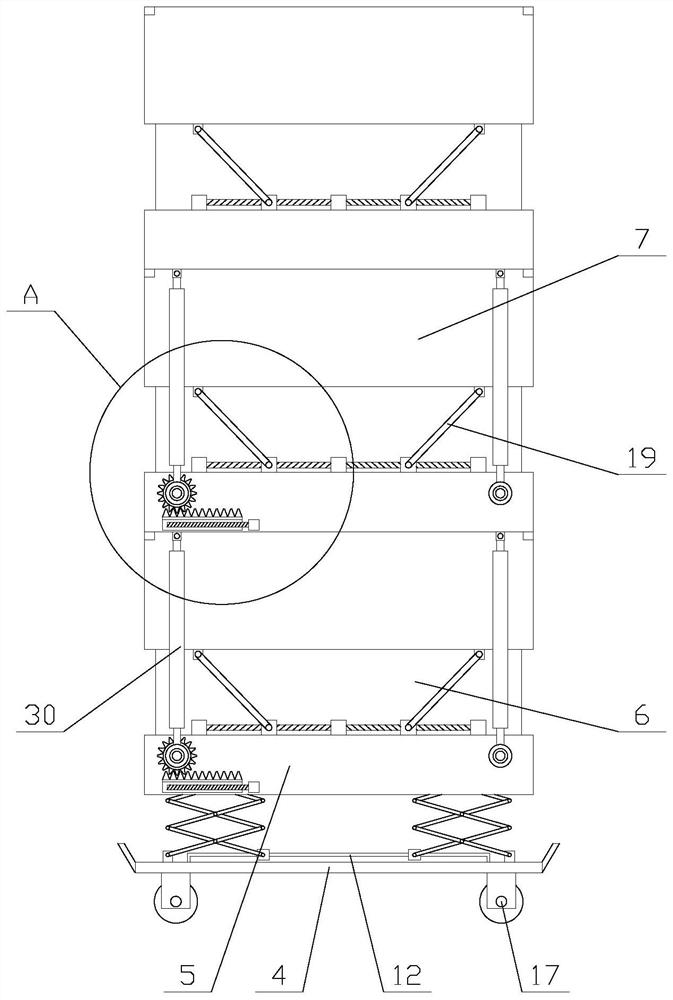

A raw material transportation system for smart factories based on 5G network

ActiveCN111003043BEnhance layeringRealize the transportation functionHand carts with multiple axesHand cart accessoriesSmart factoryTransit system

The invention relates to a 5G network-based raw material transportation system for smart factories, including a base, a transportation device and four mobile devices. The transportation device includes a bottom plate, a support mechanism, several transportation mechanisms and two booms. The transportation mechanism includes An object table, a fixed frame, a movable frame and two movable components. There are two connecting components between two adjacent stages. The connecting component includes a rotating unit and two connecting units. The supporting mechanism includes a notch, a driving component, Slide rails and two support components, this 5G network-based raw material transportation system for smart factories facilitates layered placement of raw materials through the transportation mechanism. After the equipment moves to the production link, the height of the transportation mechanism can be adjusted through the support mechanism as needed position, and use the connecting components to control the movement of the upper stage. The mechanical device at the production link obtains the raw materials in the transportation mechanism, realizes the transportation function of different raw materials, speeds up production efficiency, and improves the practicability of the equipment.

Owner:昆山科望快速印务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com