Dismantling method for building component

A technology of building components and equipment, applied in the direction of building construction, construction, building maintenance, etc., can solve the problems of high clearance requirements, large machinery occupation, time-consuming and labor-consuming, etc., achieve a high degree of integration, improve construction efficiency, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

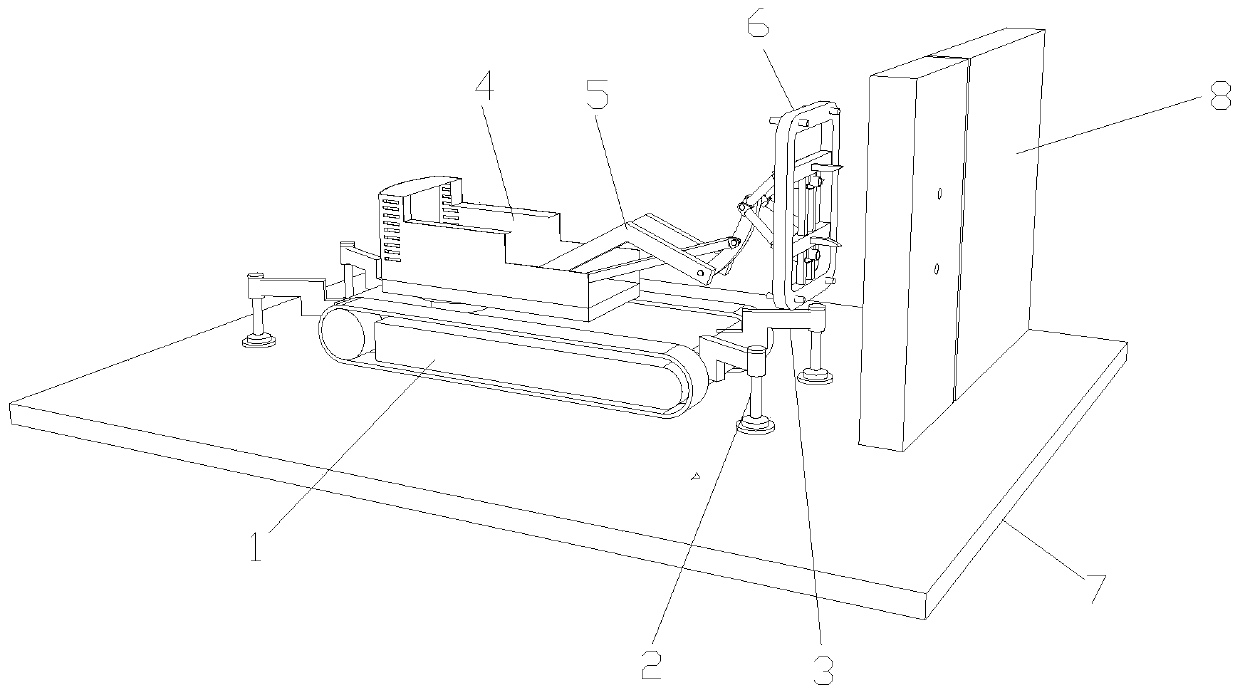

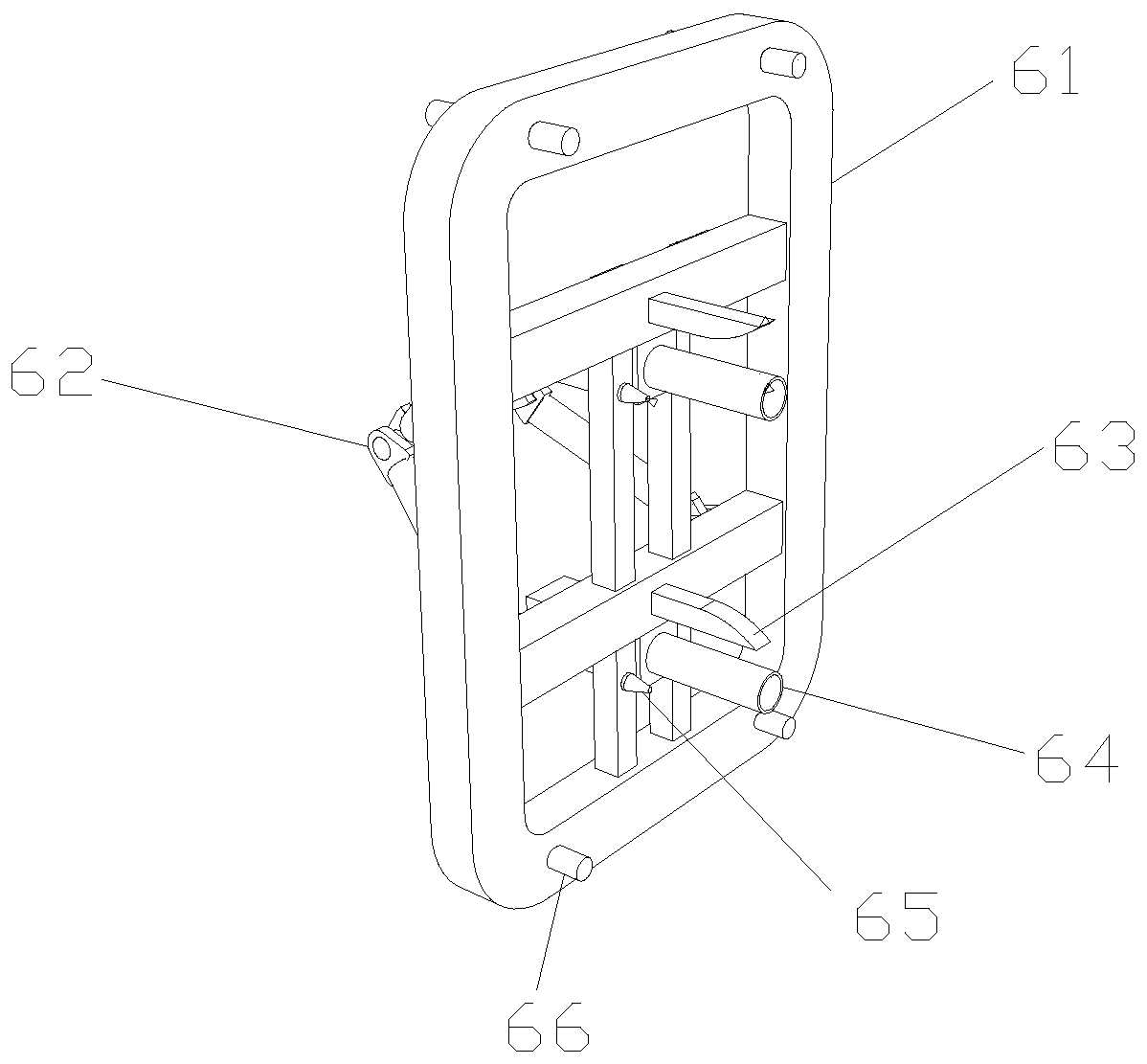

[0038] figure 1 The demolition equipment of building components is introduced, which can be used to remove building components of building beams, slabs and shear walls. Specifically, the construction component removal equipment includes a traveling device 1, a turning device 4 arranged above the traveling device 1, a mechanical arm 5 installed on the turning device 4, and a fixing device 6 arranged at the front end of the robotic arm 5. The traveling device 1 is located at On the working surface 7, the working surface can be a floor slab, and the fixing device 6 is used to dismantle the building components 8, figure 1 The middle building component 8 is a shear wall, and of course the building component can also be a beam-slab structure. The building component removal equipment can also include a number of legs 2, which can be connected to the frame of the walking device 1 through the balance arm 3, and are used to support the building component removal equipment when the buil...

Embodiment 2

[0049] This embodiment provides a method for dismantling building components. The building component removal equipment in Embodiment 1 is used to dismantle building components. The following combines Embodiment 1 and the attached Figures 1 to 4 The removal method is further described, and the removal method specifically includes the following steps:

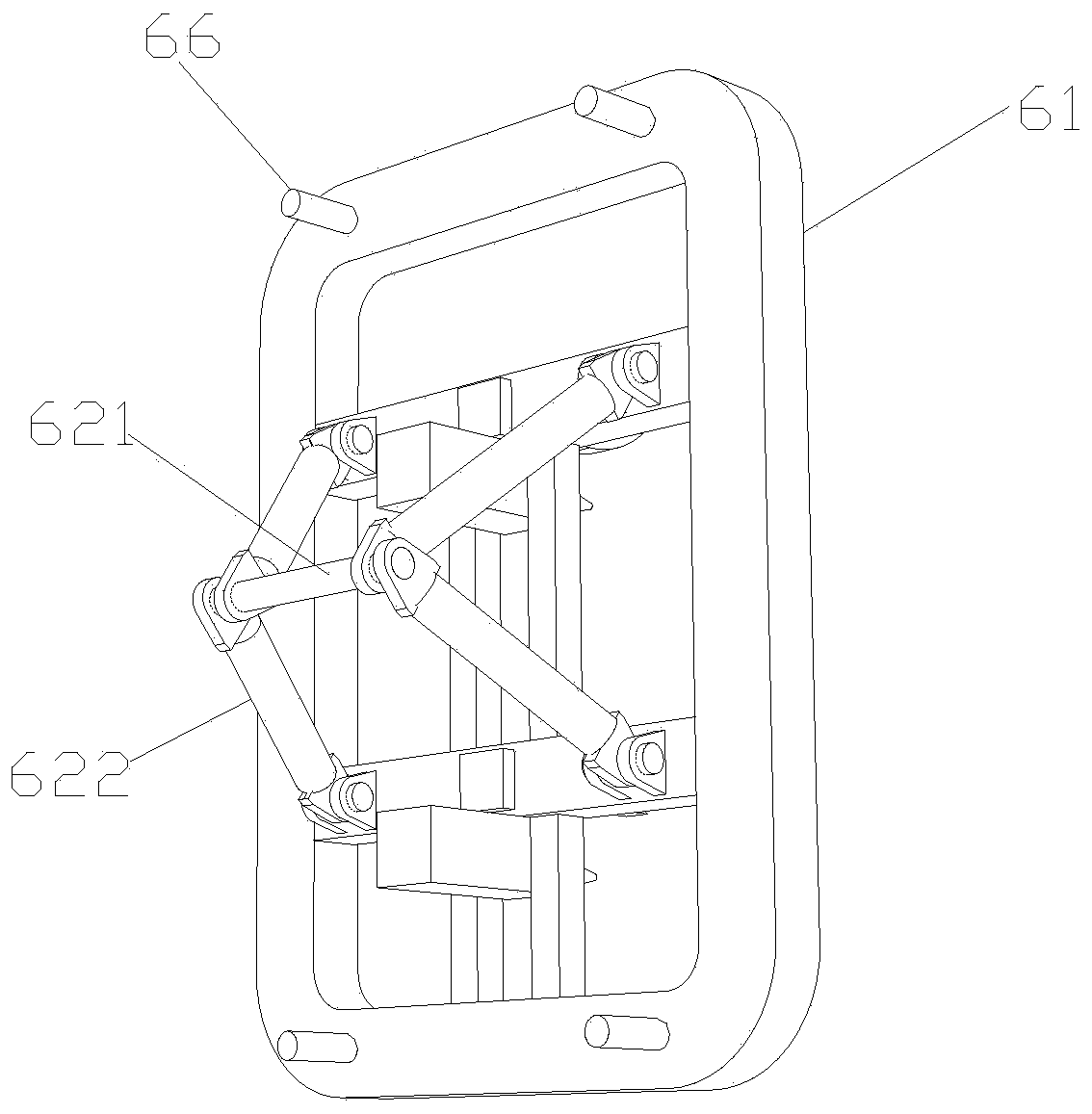

[0050] After the building component removal equipment is in place and the mechanical arm 5 makes the fixing device 6 in place, the retractable fixing pin 63 is kept retracted, and the fixing device 6 is close to and parallel to the building component 8 to be removed by adjusting the mechanical arm 5 , carry out the drilling operation, and simultaneously open the anti-flying dust water spray device 65, so that the nozzle sprays water, and the water body is recovered and clarified and reused;

[0051] After the static cutting drill bit 64 perforation is completed, the static cutting drill bit 64 is retracted so that the telescopic...

Embodiment 3

[0056] Because obstacles are often encountered on construction sites, this embodiment provides a construction component removal equipment with the function of overcoming obstacles, mainly improving the walking device in the first embodiment. combine Figure 5 and Figure 6 As shown, the traveling device includes a chassis 11 and a traveling mechanism 12 arranged on both sides of the chassis 11 . Described running mechanism 12 comprises first roller 13, second roller 14, adjustment flywheel 15, crawler belt 16, first elevator wheel system 17 and second elevator wheel system 18; Described first roller 13, first elevator wheel system 17 , the second lifting wheel system 18, and the second roller 14 are arranged on the chassis 11 in sequence; Turn and brake. combine Figure 6 and Figure 7 As shown, the first lifting wheel system 17 and the second lifting wheel system 18 both include a box body 171, a lifting device 172 arranged on the side of the box body 171, a hydraulic li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com